| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

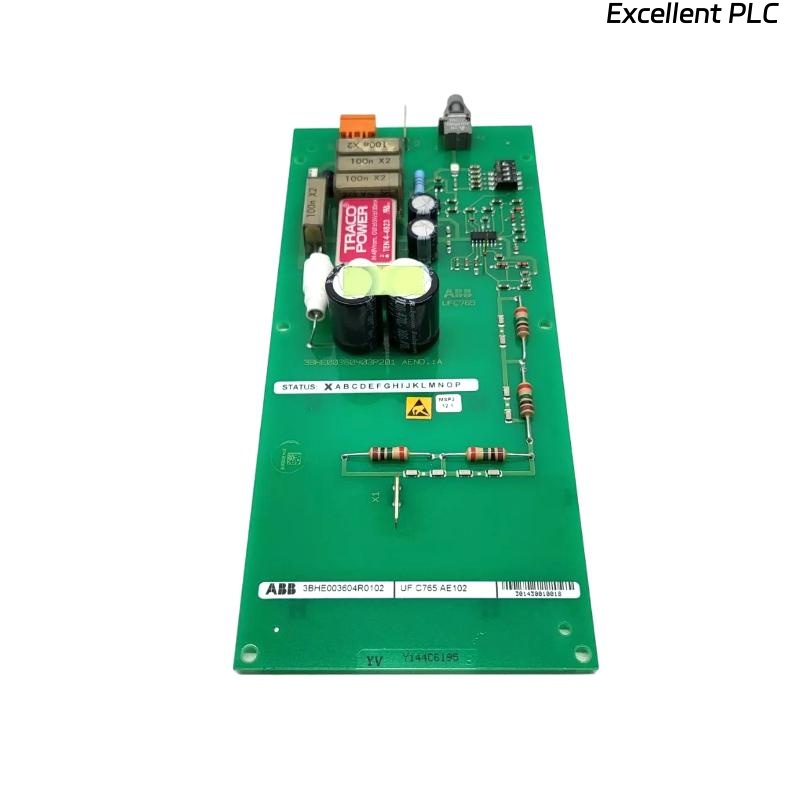

The ABB UF C765 AE102 3BHE003604R0102 Printed Circuit Board (PCB) is a vital hardware component designed for use within ABB’s sophisticated control and automation systems. This PCB serves as a key platform for mounting and interconnecting electronic components necessary to manage control functions effectively.

Manufactured with high-quality materials and precision engineering, the UF C765 AE102 PCB is optimized to support stable and reliable electrical connections, signal transmission, and processing within ABB control modules. Its design ensures compatibility with ABB’s system architectures, contributing to seamless performance in demanding industrial environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | UF C765 AE102 / 3BHE003604R0102 |

| Functionality | Printed Circuit Board (PCB) |

| Board Type | Multi-layer PCB |

| Operating Voltage | Compatible with system voltage levels |

| Signal Types | Digital and analog signal support |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions (HxWxD) | 150 x 90 x 50 mm |

| Weight | 0.2 kg |

| Mounting | Integrated within ABB control modules |

| Compliance | CE, UL, IEC standards |

Product Applications

The UF C765 AE102 PCB finds application wherever ABB control modules are deployed, providing the electrical foundation for critical automation functions. Typical usage includes:

-

Distributed Control Systems: Core board within control units responsible for managing industrial processes.

-

Power Generation Facilities: Supporting control electronics for turbines, generators, and auxiliary systems.

-

Oil & Gas Industry: Embedded in control modules for monitoring and automation of upstream and downstream equipment.

-

Chemical Processing Plants: Integral to systems controlling reactors, mixers, and safety equipment.

-

Water and Wastewater Treatment: Provides reliable platform for sensor data acquisition and process control.

-

Manufacturing Automation: Forms the backbone for motor control, robotics, and process monitoring electronics.

Product Advantages

The ABB UF C765 AE102 PCB offers several benefits essential for dependable and efficient automation hardware:

-

High-Quality Manufacturing: Uses premium materials and precise layering to ensure durability and signal integrity.

-

Stable Electrical Performance: Designed to minimize noise and interference for accurate signal transmission.

-

Compatibility: Fully compatible with ABB control system hardware, ensuring easy integration and system coherence.

-

Thermal Stability: Maintains performance within wide temperature ranges common in industrial environments.

-

Compact Form Factor: Space-efficient design facilitating integration in various module sizes.

-

Reliability: Robust construction reduces the risk of failure and downtime.

-

Ease of Maintenance: Facilitates troubleshooting and replacement due to standardized design.

-

Industry Compliance: Meets global standards for safety and electromagnetic compatibility.

-

Flexibility: Supports multiple signal types and communication interfaces.

-

Cost-Effective: Provides a reliable hardware base with long-term serviceability.

Frequently Asked Questions (FAQ)

-

What signal types does the UF C765 AE102 PCB support?

It supports both analog and digital signals used within ABB control systems. -

How does this PCB manage electromagnetic interference (EMI)?

The board design includes shielding and careful trace layout to minimize EMI and signal noise. -

What kind of communication interfaces can be supported on this PCB?

It supports interfaces compatible with ABB’s control modules, including protocols like PROFIBUS and Ethernet when integrated. -

Is the PCB designed to handle high-speed signal processing?

Yes, it is optimized for stable, high-speed data transmission within the system. -

What materials and manufacturing standards are used to ensure PCB reliability?

The PCB uses high-grade fiberglass, copper layers, and protective coatings compliant with IEC and UL standards. -

How is signal integrity maintained across this PCB?

Through multilayer construction, controlled impedance traces, and noise-reducing design features. -

Can the PCB operate reliably under industrial temperature and humidity ranges?

Yes, it is engineered to function correctly in environments from -20 °C to +70 °C and up to 95% humidity (non-condensing). -

What diagnostic capabilities are supported related to this PCB?

The PCB supports integration with control system diagnostics to monitor signal quality and detect faults. -

How is this PCB integrated into larger ABB control modules?

It is designed for modular assembly inside ABB control units, providing essential interconnections for control electronics. -

Are there specific maintenance requirements to ensure the PCB’s operational stability?

Periodic functional testing and inspection for signs of electrical degradation or contamination are recommended.

Related Models from the Same Series

| Model Number | Description | Key Features |

|---|---|---|

| UF C765 AE103 | Printed Circuit Board with enhanced shielding | Improved EMI resistance |

| UF C765 AE104 | PCB with extended signal layers | Supports additional signal channels |

| UF C765 AE105 | High-speed PCB | Designed for faster signal processing |

| UF C765 AE106 | PCB with integrated connectors | Simplifies wiring and connections |

| UF C765 AE107 | Compact PCB variant | Smaller footprint for limited space |

| UF C765 AE108 | PCB with thermal reinforcement | Enhanced heat dissipation |

Popular ABB Models from the Same Brand

| Model Number | Description | Typical Application |

|---|---|---|

| AC500 PLC | Programmable Logic Controller | Industrial automation |

| DCS800 Drive | Variable Frequency Drive | Motor control |

| PCS100 Inverter | Power Conversion System | Renewable energy applications |

| RTU540 | Remote Terminal Unit | Remote monitoring and control |

| S800 I/O Modules | Distributed Input/Output Modules | Modular system expansion |

| Freelance DCS | Distributed Control System | Process automation |

Excellent PLC

Excellent PLC