| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

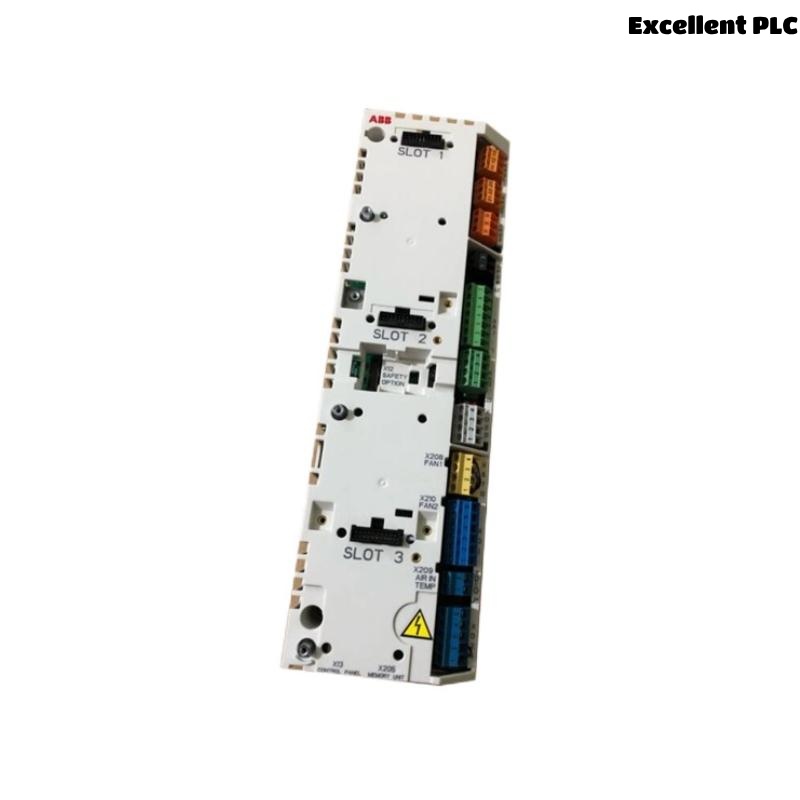

The ABB ZCU-14 Control Unit is a high-performance control device designed to deliver robust and reliable automation solutions for industrial environments. As part of ABB’s cutting-edge control unit series, the ZCU-14 is engineered to meet the increasing demands of process automation, offering advanced communication protocols, real-time processing, and flexible I/O options. With a compact yet powerful design, it is ideal for managing complex control tasks in industries such as manufacturing, process control, energy management, and automation systems integration.

This unit is a versatile control solution for controlling machinery, processes, and robotic systems. The ZCU-14 offers an intuitive user interface and advanced functionality for system integration, making it a go-to solution for both small and large-scale industrial applications.

Product Parameters

The following table highlights the key specifications of the ABB ZCU-14 Control Unit:

| Specification | Details |

|---|---|

| Model | ZCU-14 |

| Part Number | 3AXD50000005164 |

| Power Supply | 24V DC (Nominal) |

| Input Voltage Range | 20.4V to 28.8V |

| CPU Speed | 1 GHz |

| Memory (RAM) | 2 GB |

| Storage (Flash) | 16 GB |

| Communication Ports | 4 x Ethernet, 2 x RS-232, 2 x RS-485 |

| Operating Temperature | -20°C to +70°C |

| Operating Humidity | 5% to 95% (non-condensing) |

| Weight | 0.8 kg |

| Dimensions (H x W x D) | 230 x 120 x 40 mm |

Product Applications

The ABB ZCU-14 Control Unit is suitable for a wide array of industrial applications due to its flexible design and advanced capabilities. Some of its main applications include:

-

Manufacturing Automation: The ZCU-14 plays a crucial role in controlling complex manufacturing systems, ensuring high productivity and minimal downtime.

-

Process Control: It is extensively used in industries like chemical processing, petrochemical, food and beverage, and water treatment to monitor and regulate critical parameters such as pressure, flow, and temperature.

-

Building Automation: The unit can be integrated into building management systems, controlling aspects like HVAC systems, lighting, and energy management.

-

Energy Management: Used for efficient monitoring and control of energy consumption in power grids, smart grids, and renewable energy plants.

-

Robotics: The ZCU-14 helps in controlling robotic arms and automated systems for assembly, packaging, and material handling tasks.

-

Industrial Networks: It can be integrated with larger control systems to ensure seamless operation and management of distributed assets across large industrial sites.

Product Advantages

-

High Performance: The ZCU-14’s powerful 1 GHz CPU ensures fast processing speeds and smooth operation, even in high-demand automation environments.

-

Scalability: Its modular design and support for a wide range of I/O configurations make the ZCU-14 highly scalable, catering to both small and large systems.

-

Reliability: Designed for harsh industrial environments, the ZCU-14 operates reliably across a broad temperature range from -20°C to +70°C.

-

Advanced Communication: With multiple communication ports, including Ethernet and RS protocols, the ZCU-14 facilitates easy integration with other control systems and devices.

-

Enhanced Memory and Storage: The unit’s 2 GB of RAM and 16 GB of flash storage offer ample resources for handling data-heavy tasks and storing critical configurations.

-

Energy Efficiency: The ZCU-14 is designed with low power consumption in mind, contributing to energy savings in large automation systems.

-

User-Friendly Interface: The intuitive user interface allows for easy programming and system monitoring, making it accessible even to non-expert operators.

-

Wide Operating Range: With a temperature range of -20°C to +70°C and resistance to high humidity, the ZCU-14 can be used in a variety of industrial settings, from hot factories to damp environments.

FAQ (Frequently Asked Questions)

-

What industries can benefit from using the ABB ZCU-14 Control Unit?

-

The ZCU-14 is suitable for industries such as manufacturing, energy management, process control, robotics, and building automation.

-

-

What is the power supply requirement for the ZCU-14?

-

The ZCU-14 requires a 24V DC power supply, with a voltage range between 20.4V to 28.8V.

-

-

How much RAM does the ZCU-14 have?

-

The ZCU-14 is equipped with 2 GB of RAM for fast data processing.

-

-

What is the storage capacity of the ZCU-14?

-

The ZCU-14 comes with 16 GB of flash storage for storing configuration files and operating data.

-

-

What communication protocols does the ZCU-14 support?

-

It supports Ethernet, RS-232, and RS-485 communication protocols, ensuring compatibility with various systems.

-

-

Can the ZCU-14 operate in high-temperature environments?

-

Yes, it is designed to operate in environments with temperatures ranging from -20°C to +70°C.

-

-

What is the weight of the ZCU-14?

-

The ZCU-14 weighs 0.8 kg.

-

-

Is the ZCU-14 suitable for use in humid environments?

-

Yes, it can operate in environments with humidity levels from 5% to 95% (non-condensing).

-

-

What are the dimensions of the ZCU-14?

-

The dimensions are 230 x 120 x 40 mm.

-

-

How can I integrate the ZCU-14 with other ABB products?

-

The ZCU-14 offers easy integration with other ABB products using its extensive communication capabilities, including Ethernet and serial ports.

-

Recommended Models (Same Series / Related Models)

| Model | Part Number | Key Features |

|---|---|---|

| ABB ZCU-12L | 3AXD50000794058 | Compact design, lower processing power, ideal for small systems |

| ABB ZCU-16 | 3AXD50000005165 | Enhanced I/O support, additional communication ports |

| ABB ZCU-18 | 3AXD50000005166 | Increased memory and storage, higher processing speed |

| ABB ZCU-14S | 3AXD50000005167 | Optimized for energy management applications |

| ABB ZCU-20 | 3AXD50000005168 | High-performance control unit, designed for larger automation systems |

| ABB ZCU-22 | 3AXD50000005169 | Advanced version with integrated safety functions |

Popular Models (Same Brand)

| Model | Part Number | Key Features |

|---|---|---|

| ABB AC500 | 3BSE050086R1 | Modular PLC, scalable with a wide variety of I/O options |

| ABB AC800M | 3BSE050086R2 | High-performance controller for process automation |

| ABB 800xA | 3BSE050086R4 | Integrated system for advanced automation and control |

| ABB DCS System | 3BSE050086R3 | Distributed control system designed for large-scale operations |

| ABB PM800 | 3BSE050086R5 | Power management system with real-time control and monitoring capabilities |

| ABB S800 I/O System | 3BSE050086R6 | Robust I/O system suitable for industrial automation in challenging environments |

Excellent PLC

Excellent PLC