| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

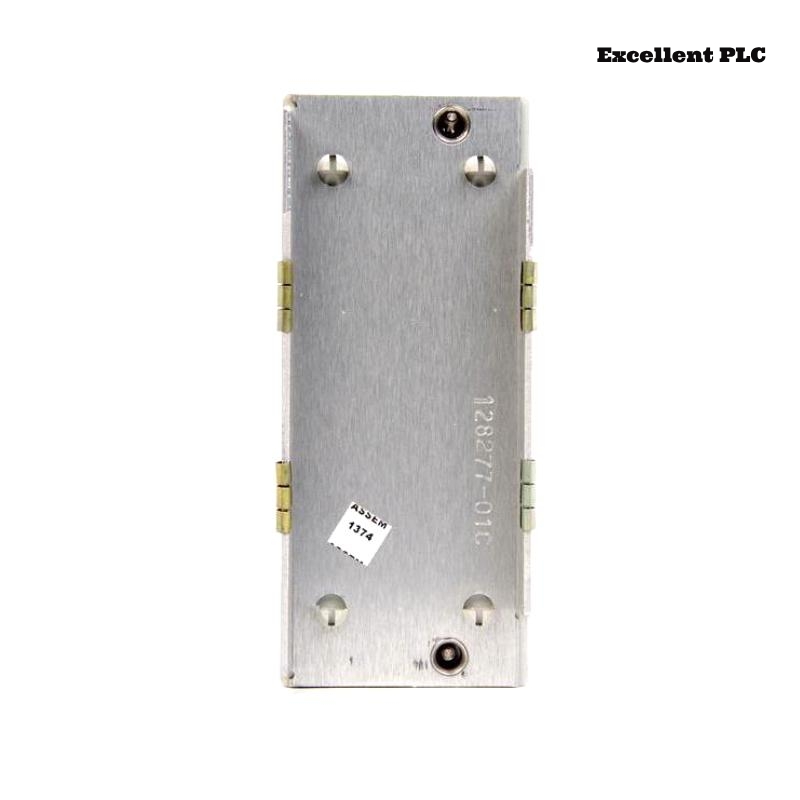

The Bently Nevada 128277-01 is a high-precision Half Height Future Expansion Panel designed to ensure the reliability and performance of critical rotating machinery. This advanced system provides real-time monitoring, early fault detection, and comprehensive diagnostics, making it an essential component in industries such as power generation, oil & gas, chemical processing, and manufacturing.

Engineered for continuous condition monitoring, the 128277-01 helps plant operators prevent costly unplanned downtime and optimize maintenance schedules. With its robust design, extensive communication capabilities, and industry-leading accuracy, this device plays a crucial role in predictive maintenance programs.

Product Specifications

| Specification | Details |

|---|---|

| Model | 128277-01 |

| Type | Half Height Future Expansion Panel |

| Operating Voltage | 24V DC |

| Power Consumption | 5W |

| Dimensions (L x W x H) | 120.7 x 50.8 mm |

| Weight | 0.5 kg |

| Temperature Range | -20°C to +65°C |

| Communication Protocols | Modbus, TCP/IP, RS485 |

| Mounting Type | DIN Rail, Surface Mount |

| Frequency Range | 5 Hz to 10 kHz |

| Sampling Rate | Up to 25,000 samples per second |

| Protection Rating | IP67 (Dustproof and Waterproof) |

| Output Signal | 4-20mA, Digital |

| Compatible Sensors | Accelerometers, Proximity Probes |

Product Applications

The Bently Nevada 128277-01 is widely used in industries that require continuous vibration monitoring for critical rotating machinery. Some of its key applications include:

-

Power Generation

- Monitors turbines, generators, and cooling fans to prevent catastrophic failures.

-

Oil & Gas

- Ensures the integrity of compressors, pumps, and drilling equipment, reducing the risk of unexpected shutdowns.

-

Petrochemical and Chemical Processing

- Provides real-time data to maintain the efficiency of reactors, agitators, and mixers.

-

Mining and Metals Processing

- Tracks the condition of crushers, conveyors, and mills, reducing maintenance costs.

-

Manufacturing and Industrial Automation

- Optimizes the performance of motors, fans, and gearboxes in production facilities.

Product Advantages

Advanced Monitoring Capabilities

- Real-time vibration data acquisition with high-speed processing ensures accurate fault detection.

Early Fault Detection

- Detects bearing wear, imbalance, and misalignment before they cause severe damage, reducing maintenance costs.

Seamless Integration

- Supports Modbus, TCP/IP, and RS485 for easy connectivity with SCADA and DCS systems.

Durable and Reliable

- IP67-rated enclosure provides protection against dust, moisture, and harsh industrial environments.

Scalable Design

- Can be deployed as a standalone unit or integrated into larger condition monitoring networks.

Flexible Installation Options

- Supports DIN rail and surface mounting, making it suitable for various installation scenarios.

Latest News Titles

- “Bently Nevada 128277-01: The Next Evolution in Vibration Monitoring”

- “How the 128277-01 is Revolutionizing Predictive Maintenance in Power Plants”

- “Cutting Costs and Improving Reliability: The Impact of Bently Nevada’s 128277-01”

- “Bently Nevada Expands Industrial IoT Capabilities with New Vibration Monitoring System”

- “Early Fault Detection: How the 128277-01 Prevents Equipment Failures”

- “Optimizing Maintenance Strategies with Bently Nevada’s Advanced Vibration Monitoring”

- “Ensuring Safe Operations in the Oil & Gas Industry with 128277-01”

- “The Role of Vibration Analysis in Modern Industrial Automation”

- “A Deep Dive into the Features of Bently Nevada’s 128277-01”

- “How Real-Time Condition Monitoring Reduces Downtime in Manufacturing”

FAQ (Frequently Asked Questions)

-

What is the primary function of the Bently Nevada 128277-01?

- It is a Half Height Future Expansion Panel used to detect early signs of machinery failure.

-

Which industries commonly use this product?

- Power plants, oil & gas, mining, chemical processing, and manufacturing industries.

-

What is the operating temperature range?

- The device operates between -20°C to +65°C.

-

Can this unit be integrated with SCADA or DCS systems?

- Yes, it supports Modbus, TCP/IP, and RS485 for seamless integration.

-

Does it work with both accelerometers and proximity probes?

- Yes, it is compatible with both accelerometers and proximity probes.

-

What kind of output signals does it provide?

- It offers both 4-20mA analog output and digital outputs.

-

Is the 128277-01 suitable for outdoor use?

- Yes, it has an IP67 rating, making it dustproof and waterproof.

-

How does the device help reduce maintenance costs?

- By detecting faults early, it helps prevent unplanned downtime and costly repairs.

-

Can multiple units be networked together?

- Yes, it supports multi-device networking for large-scale monitoring.

-

What mounting options are available?

- It supports DIN rail and surface mounting.

Recommended Models

10 Related Models (Same Series or Related)

| Model | Description | Key Features |

|---|---|---|

| 128277-02 | Advanced Vibration Monitoring System | High-speed processing |

| 128277-03 | Wireless Vibration Sensor | Remote monitoring |

| 128277-04 | Multi-Channel Vibration Monitor | Supports multiple inputs |

| 128277-05 | Explosion-Proof Vibration Sensor | Designed for hazardous areas |

| 128277-06 | Compact Vibration Monitoring Device | Space-saving design |

| 128277-07 | High-Precision Data Logger | Advanced fault detection |

| 128277-08 | Portable Vibration Analyzer | Handheld diagnostics |

| 128277-09 | Turbine-Specific Vibration Monitoring | Optimized for turbines |

| 128277-10 | Marine-Grade Vibration Sensor | Designed for offshore use |

| 128277-11 | AI-Powered Condition Monitoring System | Predictive analytics |

10 Popular Models from Bently Nevada

| Model | Description | Key Features |

|---|---|---|

| 330130-040-00 | Vibration Sensor for Large Machinery | High sensitivity |

| 330130-050-00 | Digital Vibration Monitoring System | User-friendly interface |

| 330180-040-00 | Compressor Vibration Monitor | Critical equipment safety |

| 330160-045-00 | Low-Frequency Vibration Monitoring | Optimized for large motors |

| 330120-30-10 | Machine Protection Module | Advanced diagnostics |

| 330170-050-00 | Remote Monitoring Sensor for Gas Turbines | Supports remote access |

| 330010-02 | Vibration Data Collector | Easy integration |

| 3500/22M | Machine Condition Monitoring Rack | Modular design |

| 3500/42M | Multi-Channel Monitoring Module | Expandable capabilities |

| 2300/20 | Compact Protection Monitor | Entry-level vibration monitoring |

Excellent PLC

Excellent PLC