| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

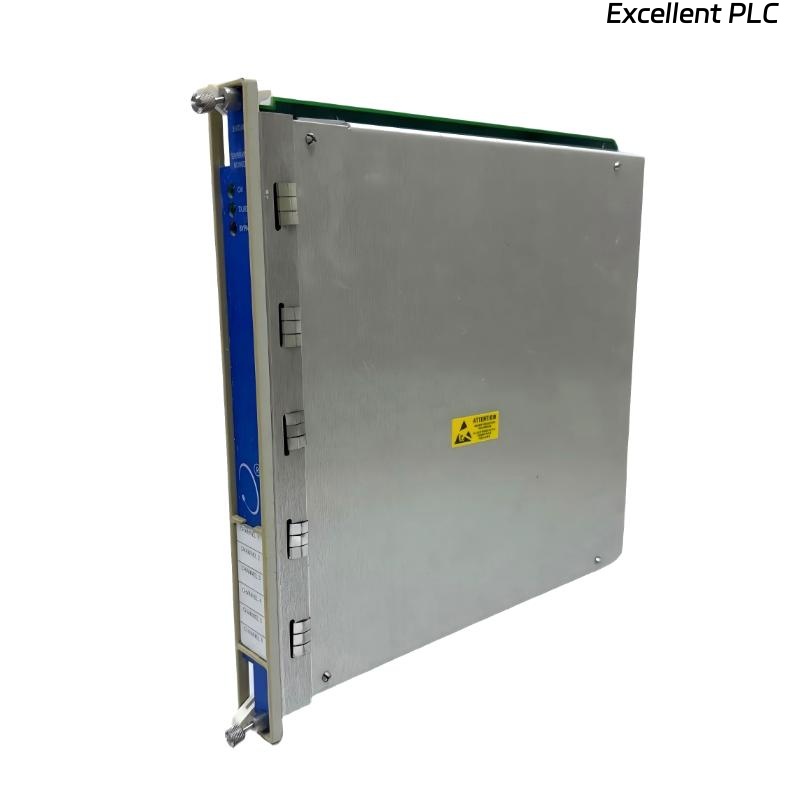

The Bently Nevada 133811-01 Temperature Monitor is a high-performance module designed to provide precise temperature measurement, monitoring, and protection for industrial equipment operating under critical conditions. It forms an integral part of the Bently Nevada machinery protection and condition monitoring system, ensuring safe and reliable plant operation.

This module is engineered for use with resistance temperature detectors (RTDs) or thermocouples, delivering accurate and continuous temperature data to the monitoring system. With its advanced signal conditioning and fault diagnostics, the 133811-01 enhances reliability in applications where precise thermal control is essential — such as turbines, compressors, generators, and other rotating machinery.

Built on Bently Nevada’s field-proven design, the module offers seamless integration with 3500 and 3300 monitoring systems, ensuring consistency and compatibility within existing infrastructure. The module’s rugged construction and superior isolation capabilities make it ideal for harsh environments, offering stable operation even under strong electrical noise or mechanical vibration.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 133811-01 |

| Product Type | Temperature Monitor Module |

| Measurement Inputs | RTD and Thermocouple (Type J, K, T, E supported) |

| Number of Channels | 2 independent temperature channels |

| Input Range | -200°C to +1200°C (depending on sensor type) |

| Accuracy | ±0.25% of reading or ±1°C (whichever is greater) |

| Input Impedance | >10 MΩ |

| Sampling Rate | 1 sample/second per channel |

| Isolation | 1500 VDC channel-to-channel and channel-to-ground |

| Output Type | 4–20 mA analog or digital via system bus |

| Power Supply | 24 VDC nominal (18–32 VDC operating range) |

| Power Consumption | 5 W typical |

| Operating Temperature | -20°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5%–95% non-condensing |

| Mounting Type | Rack-mounted |

| Interface Compatibility | Bently Nevada 3500 Series Monitoring System |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The Bently Nevada 133811-01 Temperature Monitor is widely used in industrial process automation, particularly in applications where accurate thermal data is essential for machinery protection. Common applications include:

-

Turbine temperature monitoring in power generation plants.

-

Compressor bearing and casing temperature monitoring in petrochemical facilities.

-

Generator and alternator temperature control in large-scale energy systems.

-

Motor winding and bearing temperature measurement in manufacturing and mining industries.

-

Thermal profiling of process reactors in refineries and chemical processing units.

-

Condition-based maintenance systems, integrating with vibration and position sensors for full machinery health diagnostics.

Product Advantages

-

High Measurement Precision – Ensures exceptional temperature accuracy and stability, reducing false alarms and enhancing system reliability.

-

Dual-Channel Design – Allows simultaneous monitoring of two temperature points for redundancy or multiple location coverage.

-

Comprehensive Sensor Support – Compatible with multiple RTD and thermocouple types for flexible use in various industrial processes.

-

Advanced Signal Conditioning – Minimizes noise interference and signal distortion, ensuring clean and reliable readings.

-

Easy Integration – Fully compatible with Bently Nevada 3500 systems for seamless operation within existing monitoring setups.

-

Built-In Self Diagnostics – Continuously monitors module performance and reports faults, ensuring maximum uptime.

-

Industrial-Grade Build – Resistant to vibration, humidity, and temperature variations for robust field performance.

-

Modular Replacement Design – Simplifies maintenance and reduces system downtime during module replacement.

FAQ

1. What types of temperature sensors can be connected to the 133811-01 module?

The 133811-01 supports both RTD and thermocouple sensors, including types J, K, T, and E. This flexibility allows it to be used in diverse industrial monitoring environments with different sensor configurations.

2. How does the module transmit temperature measurement data?

Temperature data is transmitted through analog 4–20 mA outputs or digitally via the Bently Nevada system backplane. This ensures compatibility with centralized monitoring and control systems.

3. Can the module function accurately in high electromagnetic interference (EMI) conditions?

Yes, the module features robust signal isolation and advanced filtering that minimize noise influence, maintaining accurate temperature readings even in environments with strong EMI or variable frequency drives.

4. What is the benefit of having a dual-channel configuration in this module?

The dual-channel design allows the module to monitor two temperature points simultaneously, which can be used for redundant measurements or to monitor different machine zones independently.

5. Is calibration required after installation or maintenance?

Although the module is factory-calibrated, periodic recalibration is recommended after maintenance, sensor replacement, or extended operation to maintain measurement accuracy and compliance with quality standards.

6. What protection features are included in the 133811-01 design?

The module provides overvoltage, overcurrent, and reverse polarity protection to safeguard both the internal electronics and connected sensors from electrical faults or transient events.

7. Can this module communicate with older Bently Nevada monitoring systems?

Yes, it offers backward compatibility with certain legacy systems in the 3300 and 3500 series. However, system configuration updates may be required for optimal communication and functionality.

8. How does the 133811-01 detect and report sensor faults?

The module continuously checks input resistance and sensor continuity. When an open circuit or abnormal resistance is detected, it automatically issues a diagnostic alert to the monitoring system.

9. What communication protocol is used between the module and the monitoring rack?

The module uses a proprietary Bently Nevada high-speed data protocol over the system backplane, ensuring reliable real-time data transmission without interference or latency.

10. What is the recommended installation orientation to ensure optimal performance?

The module should be installed vertically within the rack assembly to allow proper air circulation and efficient heat dissipation, ensuring long-term stable operation under industrial conditions.

Related Models in the Same Series

| Model | Description |

|---|---|

| 133810-01 | Dual-Channel Temperature Monitor, standard version |

| 133812-01 | Enhanced Temperature Monitor with advanced diagnostics |

| 133813-01 | Multi-Input Temperature Module supporting up to 4 channels |

| 133814-01 | RTD-only version for precision monitoring |

| 133815-01 | Thermocouple-only version with expanded range |

| 133816-01 | High-Temperature Module designed for furnace applications |

Other Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500/22M | Transient Data Interface Module |

| 3500/42M | Proximitor/Seismic Monitor |

| 3500/92 | Communication Gateway Module |

| 3500/32M | Relay Module |

| 330103-00-05-10-02-00 | Proximity Probe |

| 3500/25 | Keyphasor Module |

Excellent PLC

Excellent PLC