| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

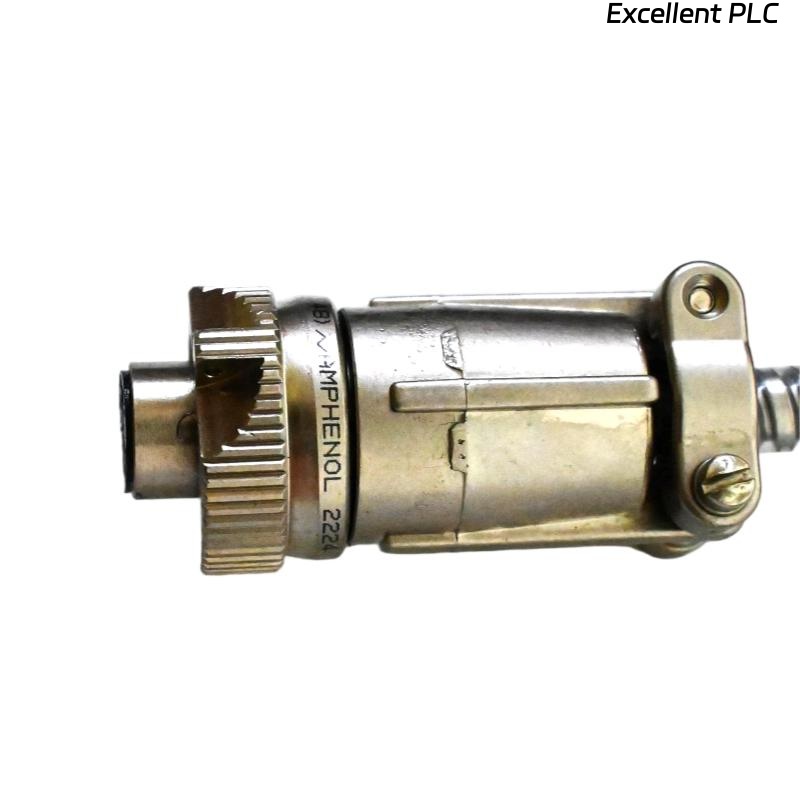

The Bently Nevada 16710-64 is a high-performance interconnect cable designed for use in vibration monitoring and condition-based maintenance systems. This rugged cable is specifically engineered to ensure the accurate and reliable transmission of signals between vibration sensors and monitoring systems in various industrial environments.

Manufactured by Bently Nevada, a global leader in condition monitoring solutions, the 16710-64 interconnect cable plays a crucial role in the vibration monitoring, machinery protection, and condition monitoring systems. It ensures that critical machinery is continually monitored, and its health can be assessed in real-time, allowing operators to detect faults or potential failures before they lead to costly downtimes.

The cable is designed to meet the stringent requirements of industries such as power generation, oil and gas, and manufacturing, where operational continuity and equipment reliability are of utmost importance. Its durable construction and excellent signal integrity make it an ideal choice for connecting various monitoring sensors to control systems.

Product Parameters

The table below outlines the key technical specifications of the Bently Nevada 16710-64 Interconnect Cable:

| Parameter | Specification |

|---|---|

| Model Number | 16710-64 |

| Cable Length | 64 ft (19.5 meters) |

| Shipping Weight | 3 kg |

| Conductor Material | Copper |

| Insulation Material | PVC |

| Shielding | Yes, for noise reduction |

| Operating Temperature | -40°C to +85°C |

| Cable Type | Multiconductor, shielded |

| Connector Type | Compatible with Bently Nevada monitoring systems |

| Application | Machinery protection, vibration monitoring, condition monitoring |

Product Applications

The Bently Nevada 16710-64 interconnect cable is specifically designed for various industrial applications where high-quality signal transmission is necessary for machinery health and operational monitoring. The key applications include:

-

Vibration Monitoring Systems: The cable connects vibration sensors to data collectors and monitoring units, ensuring that machinery performance can be continuously analyzed and potential issues can be detected early.

-

Machinery Protection: It is used in machinery protection systems that monitor critical equipment such as turbines, compressors, and motors, alerting operators to any faults or abnormalities before they cause damage or failure.

-

Condition Monitoring Systems: This cable is employed in condition monitoring systems, helping industries maintain operational efficiency by continuously monitoring machinery health and predicting when maintenance is required.

-

Power Generation Plants: The 16710-64 cable is ideal for use in power generation plants, where it connects various monitoring systems that track the performance of turbines, generators, and transformers.

-

Oil and Gas Industry: The cable is widely used in the oil and gas industry to monitor machinery and equipment in remote or challenging environments, ensuring that performance issues are detected early.

-

Manufacturing and Industrial Applications: In manufacturing settings, the cable is used for connecting vibration sensors and monitoring equipment to ensure the smooth operation of machinery such as pumps, motors, and conveyors.

Product Advantages

-

High Signal Integrity: The Bently Nevada 16710-64 ensures the reliable and accurate transmission of signals, which is critical for detecting faults and maintaining the health of machinery.

-

Shielded Design: The cable features shielding to minimize electromagnetic interference (EMI), providing stable and interference-free data transmission even in environments with high levels of electrical noise.

-

Durable and Rugged Construction: The PVC insulation provides excellent durability and protection, ensuring that the cable can withstand harsh industrial environments with high levels of vibration, heat, and mechanical wear.

-

Wide Temperature Range: With an operating temperature range from -40°C to +85°C, this cable can be used in extreme temperature conditions without compromising its performance.

-

Long Cable Length: The 64 ft (19.5 meters) cable length allows for installation in large systems or distant machinery where flexibility in cable management is required.

-

Compatible with Bently Nevada Systems: The 16710-64 is designed to work seamlessly with Bently Nevada monitoring systems, making it easy to integrate into existing setups and ensuring high compatibility and reliability.

-

Reduced Downtime: By enabling real-time monitoring and early detection of equipment issues, this cable helps reduce the risk of unexpected failures and unscheduled downtime, leading to more efficient operations.

-

Versatile Application: The cable can be used across various industries, from oil and gas to power generation, and in applications like vibration monitoring, condition monitoring, and machinery protection.

FAQ

1. What is the cable length of the Bently Nevada 16710-64?

The 16710-64 has a cable length of 64 ft (19.5 meters), providing flexibility for larger installations and longer cable runs.

2. What type of insulation is used in the 16710-64 cable?

The cable features PVC insulation, which ensures durability and resistance to wear and tear in industrial environments.

3. Is the Bently Nevada 16710-64 cable shielded?

Yes, the 16710-64 cable is shielded to minimize electromagnetic interference (EMI), ensuring stable data transmission in environments with high electrical noise.

4. What is the operating temperature range for the 16710-64 cable?

The 16710-64 operates within a temperature range of -40°C to +85°C, making it suitable for use in extreme cold and hot conditions.

5. What is the shipping weight of the 16710-64?

The shipping weight of the 16710-64 cable is 3 kg, making it easy to handle during installation and transportation.

6. Can the 16710-64 cable be used for vibration monitoring?

Yes, the cable is designed for use in vibration monitoring systems, ensuring accurate data transmission from vibration sensors to monitoring units.

7. Is the 16710-64 cable suitable for use in power plants?

Yes, the 16710-64 is ideal for use in power generation plants to connect vibration sensors and monitoring systems that track the performance of turbines, generators, and transformers.

8. How does the 16710-64 reduce signal interference?

The shielded design of the cable helps prevent electromagnetic interference (EMI), ensuring stable and high-quality signal transmission in noisy environments.

9. How does the 16710-64 cable improve machinery protection?

By enabling real-time transmission of sensor data, the 16710-64 allows monitoring systems to detect potential machinery issues early, thus reducing the risk of costly failures and unplanned downtime.

10. Can the 16710-64 be used in industrial automation systems?

Yes, the 16710-64 cable is suitable for use in industrial automation systems, where reliable data transmission is crucial for maintaining efficient and safe operations.

Recommended Models

| Model Number | Description |

|---|---|

| 16710-65 | Vibration and Condition Monitoring Cable |

| 16710-66 | High-Performance Shielded Cable for Machinery Protection |

| 16710-67 | Multiconductor Cable for Harsh Industrial Environments |

| 16710-68 | Interconnect Cable for Industrial Vibration Systems |

| 16710-69 | Shielded Signal Transmission Cable for Monitoring Systems |

| 16710-70 | High-Integrity Cable for Critical Equipment Monitoring |

Popular Models

| Model Number | Description |

|---|---|

| 16925-10 | High-Performance Shielded Cable for Vibration Monitoring |

| 16925-12 | Multiconductor Cable for Machinery Protection Systems |

| 16925-14 | Flexible Signal Cable for Condition Monitoring |

| 16925-15 | Heavy-Duty Shielded Cable for Industrial Monitoring |

| 16925-17 | Robust Vibration Monitoring Cable for Harsh Environments |

| 16925-18 | High-Integrity Cable for Equipment Condition Monitoring |

Excellent PLC

Excellent PLC