| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

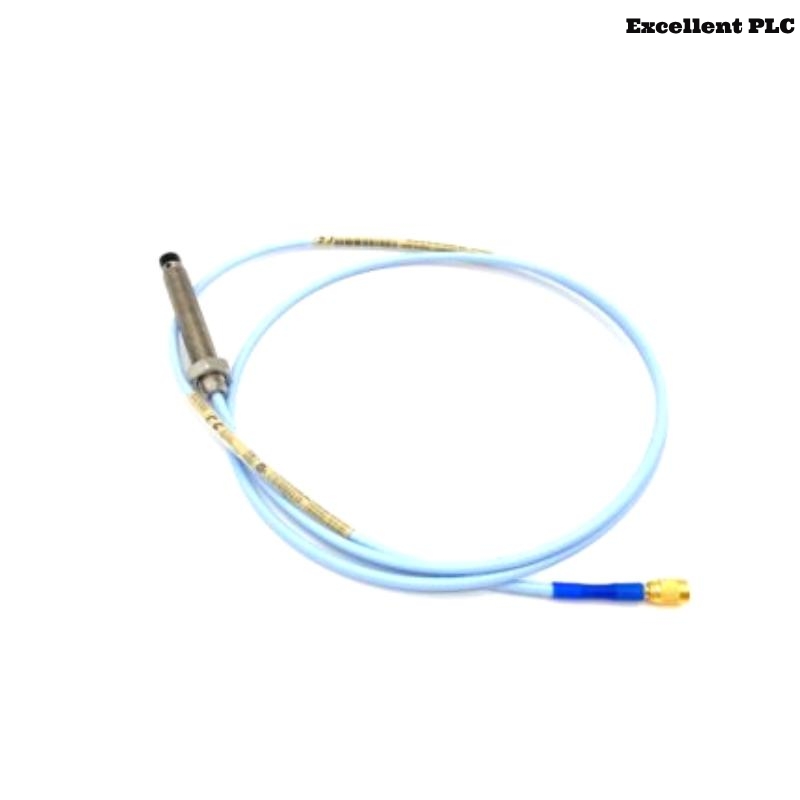

The Bently Nevada 16710-99 Interconnect Cable is a high-quality, industrial-grade cable designed to provide reliable and secure data transmission between vibration sensors and monitoring systems. Manufactured by Bently Nevada, a trusted name in machinery monitoring and predictive maintenance, this cable plays an essential role in monitoring the health and performance of critical industrial equipment. The 16710-99 interconnect cable is engineered for use in various harsh industrial environments, ensuring that real-time sensor data is reliably transmitted to monitoring systems for analysis and decision-making.

This cable is designed to meet the rigorous demands of industries like power generation, oil and gas, heavy manufacturing, and more. It supports the continuous monitoring of rotating machinery such as turbines, pumps, compressors, and motors, ensuring that any early signs of failure can be detected and addressed before they result in costly downtime or catastrophic failures.

Product Specifications

Below are the key specifications of the Bently Nevada 16710-99 Interconnect Cable:

| Parameter | Value |

|---|---|

| Product Type | Interconnect Cable |

| Model Number | 16710-99 |

| Cable Length | 99 feet |

| Conductor Material | Copper |

| Insulation Material | PVC or equivalent |

| Shielding | Double Shielded (for protection against noise) |

| Operating Temperature | -40°C to +80°C |

| Voltage Rating | 600V |

| Weight | 2.5 kg |

| Diameter | 7.0 mm (nominal) |

| Compliance | UL Listed, CE Certified |

| Connector Type | Compatible with Bently Nevada vibration sensors |

| Durability | Resistant to chemicals, moisture, and harsh conditions |

Product Applications

The Bently Nevada 16710-99 Interconnect Cable is used in several critical industrial applications. Its primary function is to connect vibration sensors to monitoring systems, ensuring the reliable transmission of data for machinery health monitoring. Below are the key applications:

-

Vibration Monitoring: This cable connects vibration sensors to data acquisition systems, enabling the monitoring of machinery such as turbines, pumps, motors, and compressors. By detecting early signs of wear or failure, it helps prevent unplanned downtime and extend equipment life.

-

Predictive Maintenance: The 16710-99 cable plays a key role in predictive maintenance systems, where real-time data from vibration sensors is used to predict potential failures and plan maintenance activities. This approach helps avoid the high costs associated with unscheduled repairs.

-

Industrial Automation: In automated industrial settings, this interconnect cable ensures that sensor data is reliably transmitted to control systems for analysis and feedback, helping optimize machine performance and system efficiency.

-

Power Generation: In power plants, this cable is used to connect vibration sensors on turbines, generators, and other critical equipment to monitoring systems, ensuring smooth and uninterrupted power production.

-

Oil and Gas: The cable is essential in oil and gas operations, where equipment reliability is crucial to safety and efficiency. It is used in both upstream and downstream sectors to monitor rotating machinery, pumps, and compressors.

-

Heavy Manufacturing: In industries that rely on large machinery, such as steel mills, paper mills, and chemical plants, the 16710-99 cable helps monitor critical equipment to prevent unplanned outages and improve operational efficiency.

Product Advantages

The Bently Nevada 16710-99 Interconnect Cable offers several key advantages, making it an ideal choice for industrial applications:

-

High Durability: The 16710-99 cable is built to withstand the harshest industrial environments. It is resistant to chemicals, moisture, high temperatures, and mechanical stress, ensuring that it continues to perform in challenging conditions.

-

Reliable Data Transmission: With double shielding and high-quality copper conductors, the cable ensures that sensor data is transmitted with minimal interference or signal degradation. This ensures accurate and consistent data, which is critical for real-time monitoring.

-

Long Cable Length: With a length of 99 feet, the cable can easily connect sensors to monitoring systems in large or distributed industrial setups, allowing for greater flexibility in installation.

-

Wide Temperature Range: Operating in temperatures from -40°C to +80°C, the cable is suitable for a wide range of environments, from freezing cold to high-temperature industrial applications.

-

Easy Installation: The cable is designed for quick and easy installation, reducing downtime during setup and enabling efficient integration with existing monitoring systems.

-

Cost-Effective Maintenance: By enabling early detection of faults, the cable helps reduce the cost of emergency repairs and unplanned downtime, contributing to a more efficient and cost-effective maintenance program.

FAQ (Frequently Asked Questions)

-

What is the primary function of the Bently Nevada 16710-99 Interconnect Cable?

-

The primary function of the cable is to connect vibration sensors to monitoring systems in industrial machinery to enable real-time monitoring of equipment health.

-

-

How long is the Bently Nevada 16710-99 cable?

-

The cable is 99 feet in length, making it suitable for large industrial applications.

-

-

What materials are used in the construction of the cable?

-

The cable features copper conductors with PVC or equivalent insulation and double shielding for noise protection.

-

-

What is the weight of the Bently Nevada 16710-99 cable?

-

The cable weighs 2.5 kg for the 99 feet length.

-

-

What is the voltage rating of the 16710-99 cable?

-

The cable has a voltage rating of 600V, which is suitable for most industrial systems.

-

-

Can the 16710-99 cable be used in outdoor environments?

-

Yes, the cable is built to withstand harsh environmental conditions, including exposure to moisture and extreme temperatures, making it suitable for outdoor use.

-

-

What is the maximum operating temperature for the 16710-99 cable?

-

The cable can operate in temperatures ranging from -40°C to +80°C.

-

-

What type of equipment is the 16710-99 cable used to monitor?

-

The cable is typically used to monitor rotating machinery such as turbines, pumps, motors, and compressors in industrial settings.

-

-

Is the 16710-99 cable compatible with other Bently Nevada sensors?

-

Yes, it is specifically designed to work with Bently Nevada vibration sensors and monitoring systems.

-

-

What are the benefits of using the 16710-99 cable in predictive maintenance?

-

The cable ensures reliable data transmission from vibration sensors, enabling early detection of equipment faults and reducing the need for costly emergency repairs and downtime.

-

Related Models from the Same Series

Below are six related models from the same product category:

| Model Number | Product Type | Key Features |

|---|---|---|

| 16710-30 | Interconnect Cable | 30-meter length for medium-range applications |

| 16710-50 | Interconnect Cable | 50-meter length for large-scale machinery monitoring |

| 16710-100 | Interconnect Cable | 100-meter length for extensive industrial setups |

| 16710-200 | Interconnect Cable | 200-meter length for very large installations |

| 16710-10 | Interconnect Cable | 10-meter length, suitable for short-distance setups |

| 16710-33 | Interconnect Cable | 33-meter length for various industrial applications |

Popular Models from Bently Nevada

Here are six popular models from Bently Nevada used in machinery monitoring and predictive maintenance:

| Model Number | Product Type | Key Features |

|---|---|---|

| 330130-040-00 | Vibration Sensor | Advanced sensor for monitoring rotating machinery |

| 3300 XL | Vibration Monitoring System | Customizable solution for machinery health monitoring |

| 3500/22 | Vibration Transmitter | High-performance transmitter for industrial systems |

| 3300/01 | Proximity Transducer | Measures displacement in rotating equipment |

| 3500/42 | Vibration Monitor | Monitors vibration and temperature in critical assets |

| 330500-01-12-10 | Vibration Probe | High-accuracy sensor for machinery health monitoring |

Excellent PLC

Excellent PLC