| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

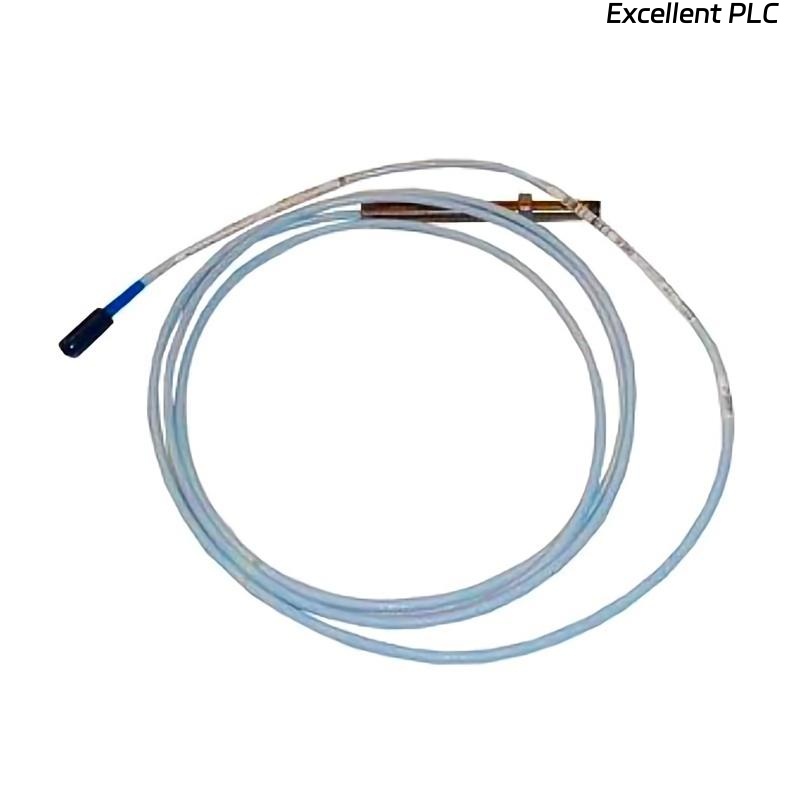

The Bently Nevada 173688-01-20-12-05 3300 XL 8 mm Proximity Probe is a precision displacement sensor designed for critical machinery monitoring. As part of the 3300 XL series, it provides accurate measurements of rotor position, vibration, and motion in high-speed rotating equipment.

This 8 mm probe is specifically engineered for high-resolution signal detection and long-term stability under harsh industrial conditions. It is widely used in turbines, compressors, generators, and pumps, ensuring reliable condition monitoring and machinery protection. The probe converts proximity signal variations into precise analog signals compatible with the 3300 XL series monitoring system.

Its robust design enables operation in high vibration, high temperature, and electrically noisy environments, maintaining measurement integrity even in extreme conditions. The 3300 XL probe series supports modular installation and is compatible with a wide range of 3300 XL modules, providing flexibility for complex monitoring setups.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 173688-01-20-12-05 |

| Type | 3300 XL Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Measurement Type | Rotor displacement / vibration |

| Output Signal | AC or DC signal compatible with 3300 XL modules |

| Probe Gap | 0.5–2.0 mm (typical) |

| Operating Temperature | -40 to 120 °C |

| Cable Type | Shielded coaxial cable |

| Total Length Option | 9 meters |

| Mounting | Threaded or clamped in probe housing |

| Frequency Response | DC to 10 kHz |

| Linearity | ±0.25% full scale |

| Insulation Resistance | >100 MΩ |

| Weight | 0.323 kg |

| Standards Compliance | IEC 61010, CE, UL |

Product Applications

The 173688-01-20-12-05 proximity probe is used for accurate rotor and vibration monitoring in critical industrial machinery:

-

Turbomachinery – Measures rotor displacement and vibration in turbines and compressors.

-

Generators – Monitors generator rotors for position deviations and vibration patterns.

-

Pumps and Motors – Provides precise feedback for condition monitoring in high-speed pumps and motors.

-

Redundant Systems – Supports dual or multi-probe configurations for critical monitoring applications.

-

Oil & Gas Industry – Installed in compressors, turbines, and rotating equipment for offshore and onshore facilities.

-

Power Generation – Enables accurate rotor monitoring in thermal, hydro, and combined-cycle power plants.

Product Advantages

-

High-Precision Measurement – Delivers ±0.25% full-scale linearity for accurate vibration and position sensing.

-

Robust Industrial Design – Withstands vibration, temperature extremes, and electrical noise.

-

Flexible Installation – Threaded or clamped mounting ensures secure positioning.

-

Compatibility – Fully compatible with 3300 XL series modules and racks.

-

Reliable Signal Transmission – Shielded coaxial cable minimizes electrical interference.

-

Wide Frequency Response – Supports DC to 10 kHz for high-speed machinery monitoring.

-

Standards Compliant – Meets IEC, CE, and UL certifications for industrial safety and reliability.

-

Modular Integration – Can be combined with other probes for multi-channel monitoring systems.

FAQ

-

What is the primary function of the 173688-01-20-12-05 probe?

It measures rotor displacement and vibration to provide accurate signals for machinery protection systems. -

What is the probe tip diameter?

The probe has an 8 mm tip, optimized for high-resolution measurement. -

Which types of machinery is this probe suitable for?

It is suitable for turbines, compressors, generators, pumps, and other high-speed rotating equipment. -

What is the typical measurement gap?

The operational probe gap ranges from 0.5 mm to 2.0 mm, depending on application requirements. -

Can this probe operate in high-temperature environments?

Yes, it is rated for -40 to 120 °C. -

What type of cable is used for signal transmission?

A shielded coaxial cable is used to minimize electrical noise and ensure accurate signal transmission. -

What is the frequency response of the probe?

It operates from DC up to 10 kHz, suitable for high-speed rotor and vibration monitoring. -

Is the probe compatible with other 3300 XL modules?

Yes, it integrates seamlessly with all 3300 XL series monitoring modules. -

Can it be used in redundant monitoring systems?

Yes, multiple probes can be installed for dual or multi-channel monitoring setups. -

How accurate is the signal output?

The probe maintains ±0.25% full-scale linearity, ensuring precise measurements for critical machinery.

Recommended Related Models (Same Series / Similar)

| Model | Description |

|---|---|

| 173688-01-10-12-05 | 3300 XL 5 mm Proximity Probe |

| 173688-01-15-12-05 | 3300 XL 6 mm Proximity Probe |

| 173688-01-25-12-05 | 3300 XL 12 mm Proximity Probe |

| 173688-02-20-12-05 | 3300 XL High-Temperature Probe |

| 173688-03-20-12-05 | 3300 XL Redundant Probe Module |

| 173688-04-20-12-05 | 3300 XL Probe with Extended Cable |

Popular Bently Nevada Models (Same Brand)

| Model | Description |

|---|---|

| 330130-040-00 | 3300 Series Vibration Transducer Module |

| 330120-010-00 | 3300 Rack Mount Analog Output Module |

| 330100-010-00 | 3300 Series Proximitor Transducer |

| 330110-020-00 | 3300 Series Internal Module for Turbine Monitoring |

| 330150-030-00 | 3300 Series Proximitor Power Supply Module |

| 330140-050-00 | 3300 Series Dual Channel Vibration Monitor |

Excellent PLC

Excellent PLC