| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

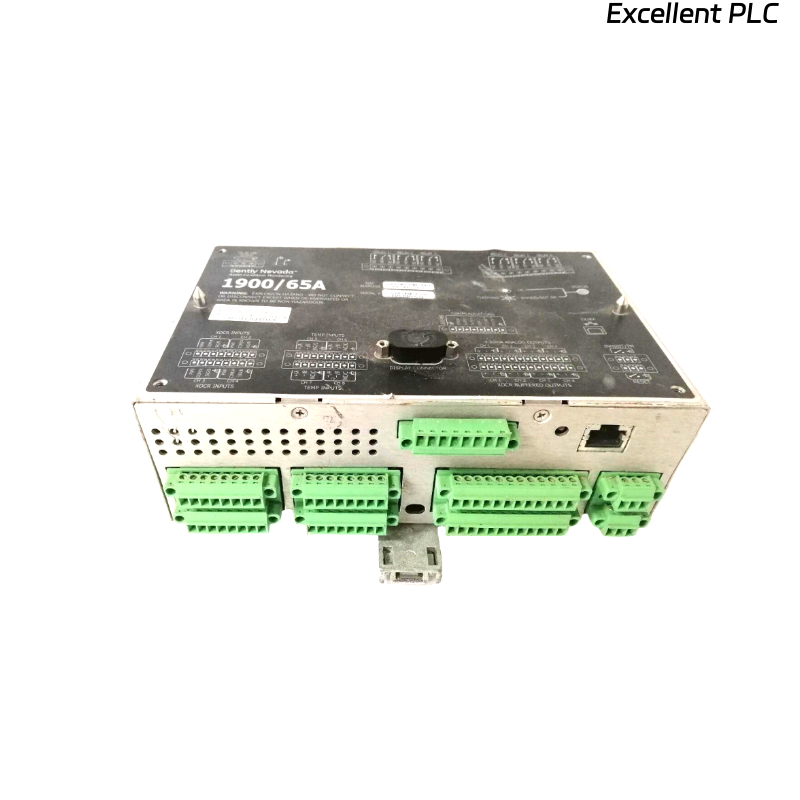

The Bently Nevada 1900/65A-01-00-01-00-00 Universal Device Monitor is an advanced, high-performance condition monitoring solution designed to provide real-time insights into the health and efficiency of industrial equipment. Whether used in critical applications such as turbines, compressors, or pumps, the 1900/65A-01-00-01-00-00 excels at monitoring key parameters like vibration, temperature, and pressure. This enables users to proactively manage maintenance schedules, reduce downtime, and extend equipment lifespans.

This model is built for environments where operational reliability is essential. It supports various industrial systems through its versatile communication protocols, and its rugged design ensures it can function under extreme industrial conditions. With its real-time data collection capabilities, the device contributes significantly to predictive maintenance strategies, enhancing the overall operational efficiency of manufacturing, power generation, and other industrial sectors.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 1900/65A-01-00-01-00-00 |

| Dimensions (L x W x H) | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.77 kg |

| Input Voltage | 24 VDC |

| Power Consumption | 2.5 W |

| Temperature Range | -20°C to +60°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Communication Protocol | Modbus, Ethernet, TCP/IP, Serial RS-232/485 |

| Mounting Type | Wall mount or DIN rail |

| Approvals | CE, UL, ATEX (optional) |

Product Applications

The Bently Nevada 1900/65A-01-00-01-00-00 Universal Device Monitor is ideal for industries that rely on continuous, real-time monitoring of machinery to ensure operational efficiency and prevent unexpected failures. Key applications include:

-

Rotating Equipment Monitoring: The device is perfect for monitoring essential rotating machinery like motors, pumps, turbines, and compressors.

-

Predictive Maintenance: By continuously monitoring vital machine health parameters, the device can detect problems early, allowing for maintenance to be scheduled before costly failures occur.

-

Condition Monitoring: Provides detailed insights into the condition of machinery in real-time, including data on vibration, temperature, and pressure, allowing operators to act quickly on abnormal readings.

-

Energy Efficiency: Helps identify and rectify inefficiencies in equipment operation, contributing to improved energy consumption across industrial facilities.

-

Harsh Environments: Built to endure the challenges posed by high temperatures, humidity, and vibrations, it is suitable for use in harsh industrial environments such as power plants, chemical refineries, and manufacturing units.

Product Advantages

-

High Precision and Sensitivity: This model offers highly sensitive data collection, which helps detect even the smallest changes in the equipment’s operational health.

-

Real-Time Monitoring: It offers live data acquisition, providing immediate insights into machinery performance and allowing operators to take corrective actions without delay.

-

Flexible Installation Options: The device can be mounted on a wall or installed on a DIN rail, providing a variety of installation options for ease of integration.

-

Durable and Reliable: Designed for the toughest industrial conditions, the monitor’s rugged build ensures long-term reliability and low maintenance requirements.

-

Comprehensive Communication Compatibility: With support for Modbus, Ethernet, TCP/IP, and Serial RS-232/485, it ensures easy integration with various industrial control systems.

-

Predictive Maintenance: The monitor’s real-time diagnostics help prevent costly repairs by identifying issues before they lead to equipment failure.

-

Scalable and Adaptable: The device can be easily scaled to monitor multiple pieces of equipment, making it suitable for both small and large industrial setups.

Frequently Asked Questions (FAQ)

-

What is the power consumption of the 1900/65A-01-00-01-00-00 device?

The device uses 2.5 watts of power during operation. -

Can this device be used in hazardous environments?

Yes, with optional ATEX certification, it is suitable for use in hazardous environments. -

What is the operational temperature range?

The operational temperature range is between -20°C and +60°C. -

How can the device be mounted?

The device can be mounted either on a wall or attached to a DIN rail for flexibility during installation. -

Does it support multiple communication protocols?

Yes, it supports Modbus, Ethernet, TCP/IP, and Serial RS-232/485 communication protocols. -

What is the weight of the 1900/65A-01-00-01-00-00?

The device weighs 0.77 kg, making it lightweight and easy to install. -

Can this device monitor multiple pieces of equipment?

Yes, it is designed to integrate into larger systems for the centralized monitoring of several devices. -

Does the device provide real-time diagnostic data?

Yes, the device continuously monitors the condition of equipment, providing real-time diagnostics and alerts. -

How does this device contribute to energy efficiency?

By monitoring machinery performance, it helps optimize operation, reducing unnecessary energy consumption. -

Is the 1900/65A-01-00-01-00-00 compatible with third-party systems?

Yes, it is compatible with a wide range of third-party control systems through its multiple communication protocols.

Additional Models from the Same Series or Related:

| Model | Description |

|---|---|

| 1900/65A-01-00-01-00-01 | Enhanced version with wireless capabilities |

| 1900/65A-01-00-01-02-00 | Designed for high-temperature environments |

| 1900/65A-01-01-01-00-00 | With extended diagnostic features for detailed monitoring |

| 1900/66A-01-00-01-00-00 | Marine-specific model for offshore applications |

| 1900/65A-01-01-02-00-00 | Includes additional vibration monitoring sensors |

| 1900/67A-01-00-01-00-00 | For critical applications requiring vibration and pressure monitoring |

Popular Bently Nevada Models:

| Model Number | Description |

|---|---|

| 190501-12-99-00 | Standard Monitoring System for Equipment |

| 200151-60-03-00 | High-Performance Diagnostic Monitoring Device |

| 190501-12-99-01 | Compact Monitoring Solution for Machinery |

| 190501-12-99-02 | Advanced Equipment Diagnostic Monitoring |

| 200151-60-03-01 | Industrial Equipment Monitoring with Alarms |

| 200151-60-03-02 | Comprehensive Monitoring System for Equipment |

Excellent PLC

Excellent PLC