| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

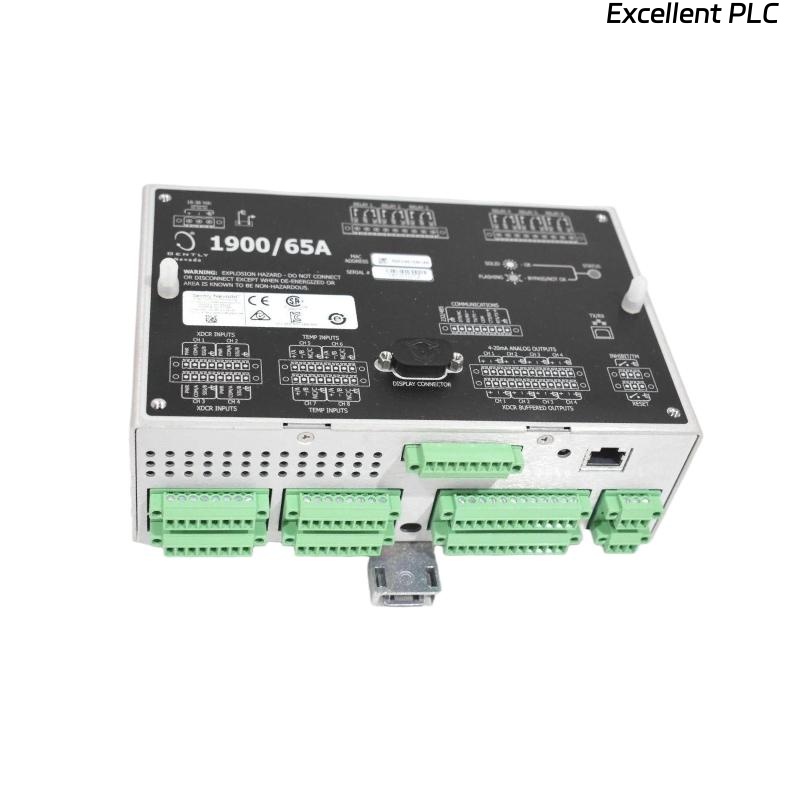

The Bently Nevada 1900/65A-01-01-03-00-00 is a versatile, reliable, and robust General Equipment Monitor designed to provide real-time monitoring for critical equipment in industrial environments. This advanced monitoring solution is ideal for detecting potential problems early, preventing costly downtime, and optimizing the performance of machinery. Part of the Bently Nevada 1900 series, the 1900/65A model offers a range of features that improve equipment performance, ensure safety, and streamline maintenance efforts.

Suitable for industries such as oil and gas, power generation, and manufacturing, this model integrates seamlessly into existing control systems and helps monitor a wide range of equipment, including pumps, compressors, turbines, and other rotating machinery. By providing data on parameters like vibration, temperature, and pressure, it helps to continuously assess the health of critical assets and supports effective predictive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 1900/65A-01-01-03-00-00 |

| Dimensions (H x W x D) | 196.9 x 149.4 x 74.4 mm |

| Weight | 0.77 kg |

| Input Voltage | 24 VDC |

| Input Current | 0.5 A |

| Output Voltage | 24 VDC |

| Communication Protocols | Modbus RTU, Ethernet/IP, Profibus |

| Operating Temperature | -10°C to +60°C |

| Mounting Type | DIN Rail / Panel Mount |

| Certifications | CE, UL |

Product Applications

The 1900/65A-01-01-03-00-00 is designed for a wide range of industrial monitoring applications:

-

Rotating Machinery Monitoring: It helps track the performance of rotating equipment such as turbines, motors, compressors, and pumps by monitoring key parameters such as vibration, temperature, and pressure.

-

Predictive Maintenance: By continuously analyzing the health of machinery, this monitor detects potential failures before they occur, allowing for proactive maintenance and reducing downtime.

-

Condition Monitoring: Continuous real-time monitoring of equipment condition ensures that any changes in performance are detected early, enabling timely corrective action.

-

Process Optimization: It enables the optimization of processes by providing data that helps operators improve system efficiency and overall production.

-

Safety Monitoring: With built-in safety features, the 1900/65A provides alerts for abnormal operating conditions, helping to prevent equipment failure and ensuring the safety of personnel and machinery.

-

Energy Efficiency: By identifying energy inefficiencies, this monitor helps in optimizing energy consumption and reducing operational costs.

Product Advantages

-

Accurate Data and Real-time Monitoring: The 1900/65A-01-01-03-00-00 provides precise, real-time monitoring data, enabling quick identification of equipment health issues, improving decision-making, and ensuring reliable operations.

-

Seamless Integration: Supporting Modbus RTU, Ethernet/IP, and Profibus, the device offers flexible communication options, making it easy to integrate into existing control and monitoring systems.

-

Predictive Maintenance Capabilities: The monitor’s ability to detect potential equipment failures before they occur helps avoid unplanned downtime, reducing repair costs and increasing the lifespan of machinery.

-

Compact and Durable: The compact size of 196.9 x 149.4 x 74.4 mm and a weight of 0.77 kg makes it easy to install in confined spaces, while its rugged design ensures it can withstand harsh industrial environments.

-

Wide Temperature Range: With an operating temperature range of -10°C to +60°C, it is well-suited for various industrial applications, from extreme heat to cold environments.

-

Versatile Monitoring Capabilities: It is designed to monitor a range of equipment, providing the flexibility to meet the needs of diverse industries and operational setups.

-

Safety and Compliance: Certified with CE and UL, this model adheres to global safety and quality standards, making it a reliable choice for critical industrial applications.

-

Energy Efficiency: The monitor identifies and helps resolve inefficiencies, contributing to a reduction in energy consumption and overall operational costs.

-

Cost Savings: By enabling timely maintenance and preventing catastrophic failures, the 1900/65A-01-01-03-00-00 contributes to significant cost savings in the long run.

FAQ

-

What types of machinery can the Bently Nevada 1900/65A-01-01-03-00-00 monitor?

The device is ideal for monitoring rotating machinery such as turbines, pumps, compressors, and motors, providing real-time data on parameters like vibration, pressure, and temperature. -

How does the 1900/65A-01-01-03-00-00 help with predictive maintenance?

By continuously tracking key performance metrics, the device helps identify early signs of wear or malfunction, allowing for maintenance before failures occur, thus preventing downtime and costly repairs. -

What communication protocols does the 1900/65A-01-01-03-00-00 support?

The device supports Modbus RTU, Ethernet/IP, and Profibus, enabling it to integrate easily with a wide range of industrial control systems. -

How does the 1900/65A-01-01-03-00-00 contribute to safety?

The device includes safety monitoring features that trigger alerts when abnormal operating conditions are detected, helping to prevent equipment failures and ensuring the safety of operators and machinery. -

Can the 1900/65A-01-01-03-00-00 be used in extreme temperature environments?

Yes, the device operates within a temperature range of -10°C to +60°C, making it suitable for use in both cold and hot industrial environments. -

What kind of alerts can the 1900/65A-01-01-03-00-00 provide?

The device provides real-time alerts for various issues such as abnormal vibrations, temperature fluctuations, and pressure irregularities, helping operators take immediate corrective actions. -

Can the device monitor multiple machines simultaneously?

Yes, the 1900/65A-01-01-03-00-00 can monitor multiple machines at once, allowing for centralized monitoring and better control over your entire system. -

How does the 1900/65A-01-01-03-00-00 optimize energy usage?

By identifying inefficiencies in machinery performance, the device provides actionable insights that help reduce energy consumption, ultimately leading to lower operational costs. -

Is the 1900/65A-01-01-03-00-00 suitable for harsh industrial environments?

Yes, the device is designed with durability in mind and can withstand harsh industrial conditions, including extreme temperatures, vibrations, and harsh chemicals. -

Can I integrate the 1900/65A-01-01-03-00-00 with a SCADA system?

Yes, the device is designed for seamless integration with SCADA systems, providing centralized monitoring and control capabilities for industrial processes.

Additional Models from the Same Series or Related:

| Model | Description |

|---|---|

| 1900/65A-01-01-01-01-01 | A version with advanced vibration monitoring and diagnostics capabilities |

| 1900/65A-01-01-02-00-00 | A model optimized for high-pressure systems, with extended monitoring capabilities |

| 1900/65A-01-01-03-00-01 | A version with added communication features for complex industrial setups |

| 1900/65A-01-01-01-01-02 | A model with enhanced data storage and reporting capabilities |

| 1900/65A-01-01-02-01-01 | A version designed for extreme temperature environments, ensuring better heat resistance |

| 1900/65A-01-01-03-01-00 | A model with integrated safety shutdown features for critical applications |

Popular Bently Nevada Models:

| Model Number | Description |

|---|---|

| 1900/65A-01-01-01-02-01 | Advanced Industrial Monitoring System |

| 1900/65A-01-01-01-BR-01 | High-performance Equipment Diagnostic Device |

| 1900/65A-01-01-02-02-01 | Robust Diagnostic Monitoring Solution |

| 1900/65A-01-01-02-BR-01 | Compact Monitoring Device for Machinery |

| 1900/65A-01-01-03-04-01 | Comprehensive Equipment Monitoring with Alarms |

| 1900/65A-01-01-03-BR-01 | Industrial Monitoring System with Enhanced Features |

Excellent PLC

Excellent PLC