| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

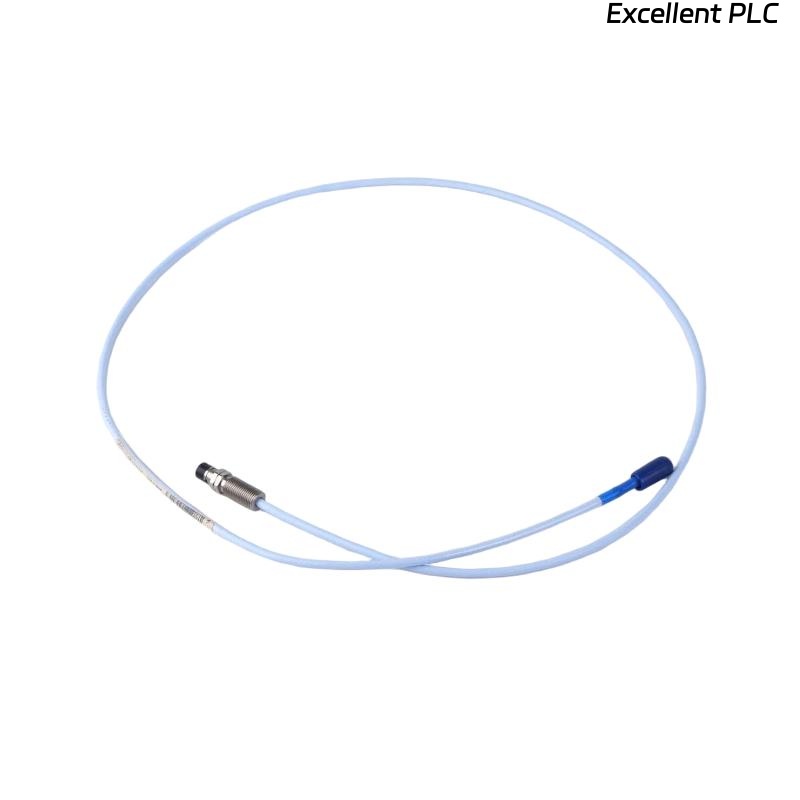

The Bently Nevada 21000-16-10-00-228-03-02 is a high-quality proximity probe housing assembly designed to protect proximity probes in industrial machinery condition monitoring systems. As a vital component in vibration and shaft displacement measurement, this housing ensures the probe remains securely positioned and shielded from environmental hazards such as dust, moisture, and mechanical vibration.

Known for its robust construction and precision engineering, this assembly supports accurate and reliable data acquisition critical for predictive maintenance in heavy-duty rotating equipment. It is widely utilized across industries such as power generation, oil and gas, manufacturing, and marine applications to extend machinery life and avoid unexpected failures.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 21000-16-10-00-228-03-02 |

| Product Type | Proximity Probe Housing Assembly |

| Material | Stainless Steel |

| Supported Probe Diameter | Typically 8 mm (standard proximity probes) |

| Mounting Style | Threaded or flange mount (application dependent) |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Resistant to dust, moisture, and vibration |

| Compatible Probes | Bently Nevada proximity probes and equivalents |

| Certifications | Meets industrial and safety standards |

Applications

The housing assembly plays an essential role in protecting proximity probes across various industries and equipment types, including:

-

Power Generation: Monitoring turbines, generators, and large motors for vibration and shaft position.

-

Oil & Gas: Securing probes in pumps, compressors, and drilling equipment operating in extreme environments.

-

Manufacturing: Monitoring critical rotating machinery to detect wear, misalignment, or imbalance early.

-

Marine and Offshore: Corrosion-resistant housing suitable for shipboard engines and auxiliary machinery.

-

Aerospace: Supporting condition monitoring in specialized rotating equipment.

-

Heavy Industry: Protecting probes in cement, steel, and paper mill machinery.

Advantages

-

Robust Construction: Built from corrosion-resistant stainless steel, providing long-term durability in harsh conditions.

-

Precision Fit: Designed for stable and accurate probe placement, enhancing data accuracy.

-

Wide Operating Range: Functions reliably between -40°C and +125°C, accommodating diverse industrial environments.

-

Flexible Mounting Options: Offers both threaded and flange mounting for ease of installation.

-

Environmental Protection: Shields probes from moisture, dust, and vibration to maintain performance integrity.

-

Lightweight: Weighs just 1.1 kg, minimizing added load on machinery.

-

Reduced Maintenance: Durable materials and construction lower maintenance frequency and costs.

-

Proven Performance: Trusted by industry leaders worldwide in critical machinery monitoring applications.

-

Compatibility: Seamlessly integrates with Bently Nevada standard proximity probes for optimized system performance.

Frequently Asked Questions (FAQ)

-

What is the main role of the proximity probe housing?

It holds and protects the proximity probe, making sure it stays securely in place to provide accurate vibration and shaft displacement readings. -

Can this housing withstand tough industrial environments?

Yes, it’s made from stainless steel and designed to resist dust, moisture, and mechanical shocks common in industrial settings. -

What is the size of probes that this housing supports?

It’s designed to fit standard proximity probes with a diameter of around 8 mm. -

How do I install this housing on my equipment?

You can mount it either by threading or using a flange, depending on your machine’s design. -

Will using this housing affect the accuracy of my measurements?

When installed properly, it stabilizes the probe, ensuring consistent and accurate readings. -

What temperature conditions can this housing operate in?

It works reliably in a temperature range from -40°C up to +125°C, suitable for most industrial applications. -

Does the housing require any special maintenance?

Generally, just routine checks for signs of wear or corrosion are enough to keep it in good condition. -

Is this housing suitable for outdoor or marine environments?

Yes, the corrosion-resistant material makes it suitable for harsh environments, including marine applications. -

How do I know if this housing fits my specific probe model?

Check your probe’s diameter and mounting type against the housing specifications, or consult with technical support if unsure. -

What should I do if the housing gets damaged?

Replace it promptly to avoid compromising probe stability and measurement accuracy.

Recommended Related Models (Same Series or Related)

| Model Number | Description | Length (mm) | Diameter (mm) | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 21000-16-10-00-228-03-01 | Proximity Probe Housing Assembly | 115 | 29 | 0.20 | Slightly smaller variant |

| 21000-16-10-00-228-04-01 | Housing with Flange Mount | 125 | 30 | 0.23 | Flange mounting option |

| 21000-16-10-00-228-05-01 | High Temperature Housing Assembly | 120 | 30 | 0.21 | For use in elevated temperature conditions |

| 21000-16-10-00-228-06-01 | Compact Housing Assembly | 95 | 25 | 0.17 | For installations with space constraints |

| 21000-16-10-00-228-07-01 | Housing with Enhanced Seal | 120 | 32 | 0.22 | Additional environmental sealing |

| 21000-16-10-00-228-08-01 | Heavy Duty Housing Assembly | 130 | 33 | 0.25 | Designed for heavy industrial use |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Type | Key Feature | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 330105-00-02 | 3500 Series Proximity Probe | Proximity Probe | High accuracy, rugged design | 0.10 | Commonly used in turbine monitoring |

| 330103-00-02 | 3500 Series Vibration Sensor | Vibration Sensor | Piezoelectric technology | 0.12 | Reliable for vibration measurement |

| 134-680-00 | 3500/50 Vibration Monitor Module | Monitor Module | Real-time vibration analysis | 0.25 | Integrated monitoring solution |

| 134-126-00 | 3500/46 Vibration Monitor Module | Monitor Module | High sensitivity monitoring | 0.22 | Popular in power generation plants |

| 330120-00 | 3500 Series Speed Sensor | Speed Sensor | Precise shaft speed detection | 0.08 | Essential in rotating machinery |

| 330110-00 | 3500/22 Proximitor Sensor | Proximitor Sensor | Shaft displacement detection | 0.11 | Core component in condition monitoring systems |

Excellent PLC

Excellent PLC