| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

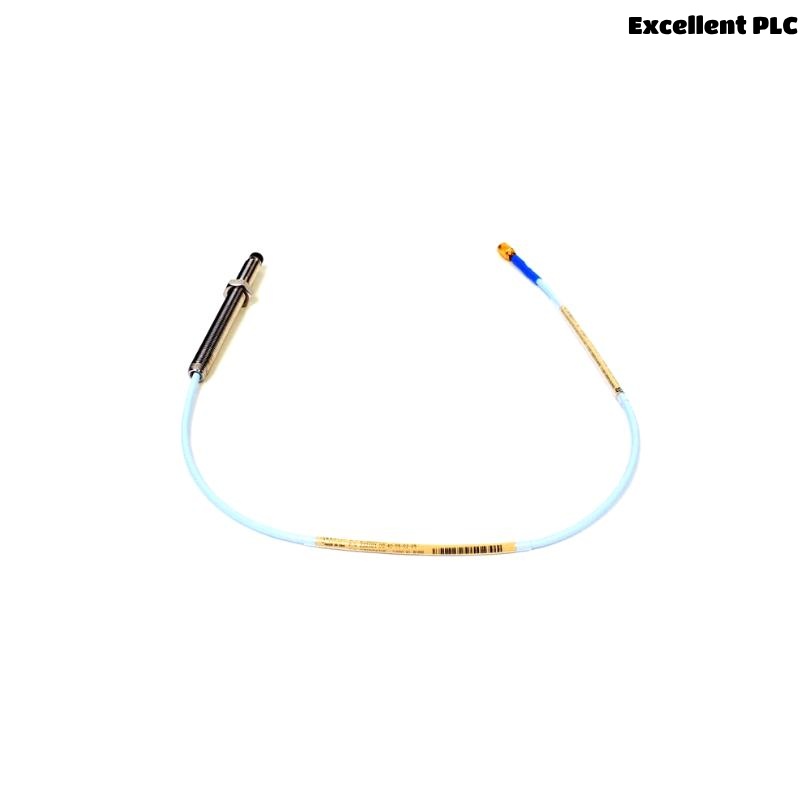

The Bently Nevada 21000-16-10-15-067-03-02 Proximity Probe Housing Assembly is a precision-engineered component designed to securely mount and protect proximity probes used in critical machinery monitoring systems. These housing assemblies ensure the probes remain stable and properly aligned, which is essential for accurate measurement of shaft displacement and vibration in rotating equipment.

Manufactured from high-quality stainless steel, this housing assembly provides robust protection against harsh industrial environments, including exposure to dust, moisture, and mechanical shocks. It is widely employed in sectors where continuous machinery health monitoring is vital, such as power generation, oil and gas, petrochemical, and heavy industry.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 21000-16-10-15-067-03-02 |

| Product Type | Proximity Probe Housing Assembly |

| Material | Stainless Steel |

| Probe Diameter Compatibility | Typically 8 mm diameter proximity probes |

| Mounting Type | Threaded or flange mount (application specific) |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Dust and moisture resistant, vibration tolerant |

| Compatible Probes | Bently Nevada proximity probes and equivalents |

| Certifications | Compliant with relevant industry standards |

Applications

The 21000-16-10-15-067-03-02 housing assembly is integral in many industries for safeguarding proximity probes used in machinery condition monitoring:

-

Power Generation: For turbines, generators, and large motors to monitor shaft position and vibration, helping to prevent failures.

-

Oil & Gas: Used on compressors, pumps, and drilling equipment for early detection of mechanical issues.

-

Petrochemical Plants: Protects probes in harsh environments, ensuring continuous monitoring of rotating equipment.

-

Manufacturing: Applies to heavy machinery such as gearboxes and conveyors where vibration monitoring is crucial.

-

Marine Industry: Suitable for use on ship engines and auxiliary systems due to corrosion-resistant construction.

-

Mining & Heavy Industry: Supports equipment monitoring in challenging and abrasive environments.

Advantages

-

Robust Construction: Made from corrosion-resistant stainless steel to ensure durability and longevity in tough industrial environments.

-

Accurate Positioning: Keeps the probe firmly in place, preventing movement that could distort measurements.

-

Wide Temperature Tolerance: Operates effectively in environments from -40°C up to +125°C.

-

Flexible Mounting Options: Designed to accommodate threaded or flange mounting for various installation setups.

-

Environmental Protection: Shields the probe from dust, moisture, and vibration, maintaining sensor integrity.

-

Lightweight: Weighing 1.1 kg, it adds minimal mass to the monitored machinery.

-

Low Maintenance: Requires minimal upkeep, with simple periodic inspections recommended.

-

Industry Trusted: Widely adopted in mission-critical applications worldwide.

-

Compatibility: Tailored to fit standard Bently Nevada proximity probes, enabling easy integration.

Frequently Asked Questions (FAQ)

-

What is the purpose of this housing assembly?

It secures and protects the proximity probe to ensure accurate monitoring of shaft displacement and vibration. -

What material is the housing made from?

The housing is made from stainless steel, offering strong resistance to corrosion and mechanical damage. -

Is it suitable for harsh industrial conditions?

Yes, it is designed to withstand dust, moisture, vibration, and temperature extremes common in industrial settings. -

Which probe sizes does it accommodate?

It is compatible with proximity probes of approximately 8 mm diameter. -

How is the housing installed on machinery?

It can be mounted using either threaded fittings or flange mounts depending on the equipment requirements. -

Does the housing impact the accuracy of the probe?

When installed correctly, it ensures the probe remains stable, thereby maintaining measurement precision. -

What temperature range can it operate within?

It supports operational temperatures from -40°C to +125°C. -

How often should the housing be inspected or maintained?

Regular visual inspections for corrosion or physical damage are advised; routine maintenance is minimal. -

Is this housing suitable for marine environments?

Yes, its stainless steel design makes it resistant to corrosion from saltwater and suitable for marine applications. -

What should I do if the housing is damaged?

Replace the housing immediately to prevent inaccurate readings or probe damage.

Recommended Related Models (Same Series or Related)

| Model Number | Description | Length (mm) | Diameter (mm) | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 21000-16-10-15-057-03-02 | Standard Proximity Probe Housing | 110 | 28 | 0.20 | Common industrial use |

| 21000-16-10-15-057-04-02 | Housing with Flange Mount | 115 | 29 | 0.22 | Flange mounting option |

| 21000-16-10-15-067-05-03 | High-Temperature Housing | 120 | 31 | 0.25 | For elevated temperature environments |

| 21000-16-10-15-067-06-01 | Compact Housing for Space-Limited Areas | 95 | 26 | 0.18 | Fits tight installation spots |

| 21000-16-10-15-067-07-02 | Heavy-Duty Environmental Seal Housing | 125 | 32 | 0.27 | Enhanced environmental seals |

| 21000-16-10-15-067-08-01 | Rugged Industrial Use Housing | 130 | 33 | 0.28 | Built for extreme conditions |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Type | Key Feature | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 330105-00-02 | 3500 Series Proximity Probe | Proximity Probe | High accuracy and durability | 0.10 | Widely used in turbine monitoring |

| 330103-00-02 | 3500 Series Vibration Sensor | Vibration Sensor | Piezoelectric technology | 0.12 | Reliable for vibration analysis |

| 134-680-00 | 3500/50 Vibration Monitor Module | Monitor Module | Real-time vibration monitoring | 0.25 | Integrated condition monitoring |

| 134-126-00 | 3500/46 Vibration Monitor Module | Monitor Module | High sensitivity | 0.22 | Power generation applications |

| 330120-00 | 3500 Series Speed Sensor | Speed Sensor | Accurate shaft speed detection | 0.08 | Essential for rotating machinery |

| 330110-00 | 3500/22 Proximitor Sensor | Proximitor Sensor | Shaft displacement measurement | 0.11 | Core sensor in monitoring systems |

Excellent PLC

Excellent PLC