| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

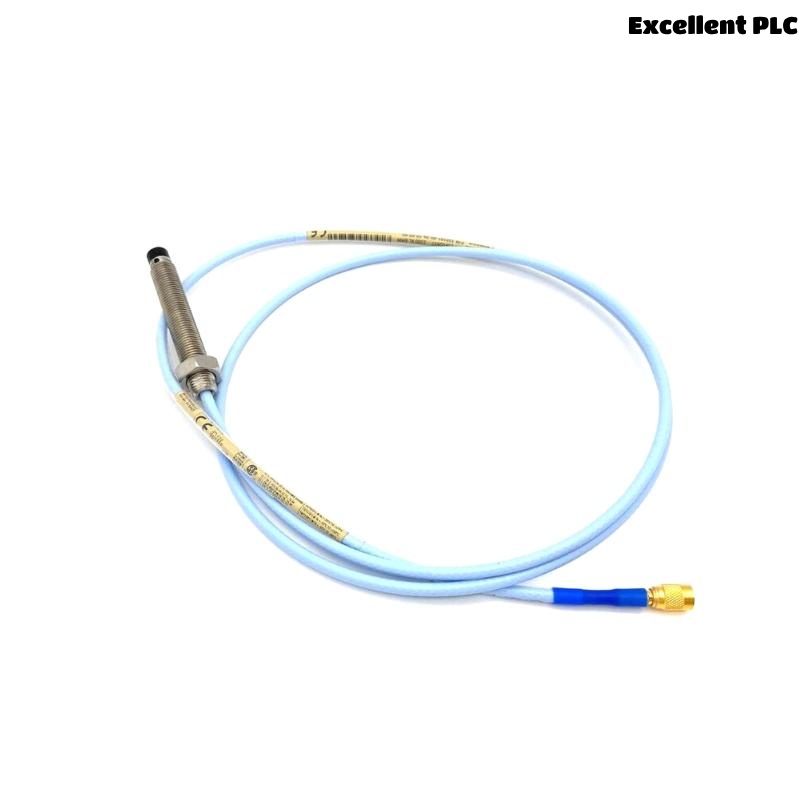

The Bently Nevada 21000-16-10-15-072-03-02 Proximity Probe Housing Assembly is a high-quality mechanical component engineered to protect and securely mount proximity probes used for precise monitoring of rotating machinery. Designed with durability and precision in mind, this housing ensures that the proximity probes maintain optimal positioning, thereby delivering accurate measurements of shaft displacement and vibration critical to machinery condition monitoring.

Constructed from corrosion-resistant stainless steel, the housing withstands demanding industrial environments — including extreme temperatures, moisture, dust, and mechanical shocks. This assembly is a key part of condition monitoring systems widely used in industries where equipment reliability and uptime are vital, such as power plants, oil and gas facilities, petrochemical plants, and heavy manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 21000-16-10-15-072-03-02 |

| Product Type | Proximity Probe Housing Assembly |

| Material | Stainless Steel |

| Probe Diameter Compatibility | Typically 8 mm diameter proximity probes |

| Mounting Type | Threaded or flange mounting depending on setup |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Resistant to dust, moisture, and vibration |

| Compatible Probes | Standard Bently Nevada proximity probes and equivalents |

| Certifications | Meets industry standards for rugged industrial use |

Applications

This housing assembly plays a critical role in a broad range of machinery monitoring applications:

-

Power Generation: Ensures stable probe installation for turbines, generators, and motors, allowing precise vibration and position sensing.

-

Oil & Gas: Used on compressors, pumps, and rotating equipment to monitor mechanical health and prevent costly failures.

-

Petrochemical Plants: Protects probes in harsh chemical environments, helping maintain continuous machine monitoring.

-

Heavy Manufacturing: Fits large industrial machinery such as gearboxes and conveyors requiring reliable vibration analysis.

-

Marine Industry: Stainless steel construction offers corrosion resistance, ideal for engine and auxiliary system monitoring on ships.

-

Mining Industry: Supports probe protection in abrasive and rough environmental conditions common in mining operations.

Advantages

-

Durability: Manufactured from high-grade stainless steel to resist corrosion, mechanical stress, and harsh environmental factors.

-

Precision: Secures the probe firmly, maintaining accurate positioning critical for reliable measurements.

-

Temperature Resilience: Effective operation across a broad temperature range from -40°C to +125°C.

-

Versatile Mounting: Compatible with multiple mounting configurations, including threaded and flange mounts.

-

Environmental Shield: Protects probes from dust ingress, moisture, and mechanical vibration, prolonging probe lifespan.

-

Lightweight Design: Weighs 1.1 kg, contributing minimal additional load to machinery.

-

Low Maintenance: Requires minimal upkeep, with simple periodic inspections to ensure performance.

-

Widely Used: Trusted in industries where machine uptime and reliability are paramount.

-

Compatibility: Designed for seamless integration with Bently Nevada proximity probes, simplifying installation and replacement.

Frequently Asked Questions (FAQ)

-

What is the main function of this housing assembly?

It secures and protects proximity probes to ensure accurate and reliable shaft position and vibration monitoring. -

What materials are used in its construction?

The housing is made from stainless steel, providing excellent corrosion resistance and durability. -

Can this housing assembly withstand harsh environments?

Yes, it is designed to resist dust, moisture, vibration, and a wide temperature range. -

Which size probes are compatible with this housing?

It typically fits proximity probes with an 8 mm diameter. -

What types of mounting methods are supported?

Both threaded and flange mounting options are supported depending on the application requirements. -

Does the housing affect the accuracy of the probe readings?

When installed correctly, it ensures probe stability, helping maintain accurate measurements. -

What is the operational temperature range?

It can operate safely between -40°C and +125°C. -

How often should the housing be checked or maintained?

Regular inspections for damage or corrosion are recommended, but overall maintenance requirements are low. -

Is it suitable for use in marine or corrosive environments?

Yes, its stainless steel build makes it resistant to corrosion typical in marine or chemical environments. -

What should be done if the housing shows signs of damage?

The housing should be replaced immediately to prevent compromised probe performance.

Recommended Related Models (Same Series or Related)

| Model Number | Description | Length (mm) | Diameter (mm) | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 21000-16-10-15-067-03-02 | Standard Probe Housing Assembly | 115 | 30 | 0.22 | Industrial standard use |

| 21000-16-10-15-057-03-02 | Compact Housing for Tight Spaces | 110 | 28 | 0.20 | Space-constrained areas |

| 21000-16-10-15-072-04-02 | Flanged Mount Housing Assembly | 120 | 31 | 0.24 | Flange mounting version |

| 21000-16-10-15-067-06-01 | High-Temperature Resistant Housing | 125 | 33 | 0.26 | For elevated temperature |

| 21000-16-10-15-067-07-02 | Heavy-Duty Housing with Enhanced Seal | 130 | 32 | 0.27 | Improved environmental seal |

| 21000-16-10-15-072-05-02 | Rugged Housing for Extreme Environments | 135 | 34 | 0.28 | Designed for harshest conditions |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Type | Key Feature | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 330105-00-02 | 3500 Series Proximity Probe | Proximity Probe | High accuracy and durability | 0.10 | Standard turbine monitoring |

| 330103-00-02 | 3500 Series Vibration Sensor | Vibration Sensor | Piezoelectric technology | 0.12 | Reliable vibration detection |

| 134-680-00 | 3500/50 Vibration Monitor Module | Monitor Module | Real-time monitoring | 0.25 | Comprehensive monitoring |

| 134-126-00 | 3500/46 Vibration Monitor Module | Monitor Module | High sensitivity | 0.22 | For power generation equipment |

| 330120-00 | 3500 Series Speed Sensor | Speed Sensor | Accurate shaft speed detection | 0.08 | Key for rotating machinery |

| 330110-00 | 3500/22 Proximitor Sensor | Proximitor Sensor | Shaft displacement measurement | 0.11 | Core sensor in monitoring |

Excellent PLC

Excellent PLC