| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

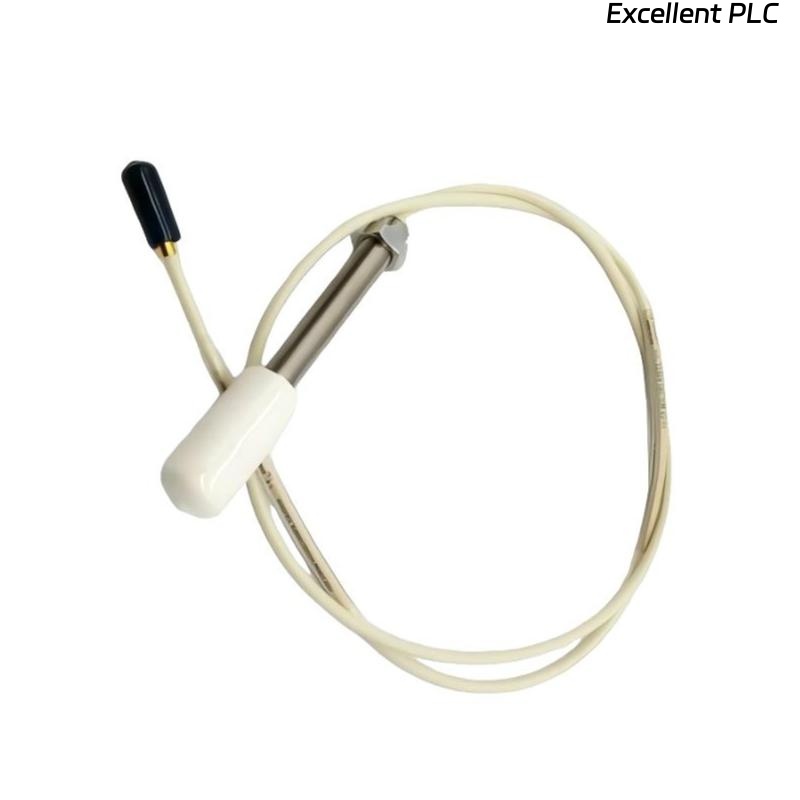

The Bently Nevada 21504-000-052-10-02 7200 8mm Standard Mount Probe is a precision displacement probe designed for rotating machinery monitoring and vibration analysis. As part of the 7200 Series, it provides reliable, high-fidelity measurements of shaft position and vibration, which are critical for machinery protection, condition monitoring, and predictive maintenance programs.

This probe features an 8 mm tip diameter with a 1.0-metre integrated cable, offering flexibility for sensor placement and installation. Its design ensures accurate signal transmission to 7200 Series monitoring systems, maintaining high-resolution readings even in challenging industrial environments. The robust construction allows it to withstand mechanical vibration, temperature variations, and electromagnetic interference.

The 21504-000-052-10-02 is widely used in turbines, compressors, motors, pumps, and other rotating equipment, enabling operators to detect early signs of mechanical problems such as unbalance, misalignment, or bearing wear.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 21504-000-052-10-02 |

| Series | 7200 Series |

| Probe Type | Standard mount displacement probe |

| Tip Diameter | 8 mm |

| Total Length | 1.0 metre |

| Weight | 0.22 kg |

| Cable Type | Shielded for low-noise signal transmission |

| Operating Temperature Range | -40°C to +85°C |

| Material | Stainless steel probe body, durable insulated cable |

| Signal Type | Analog displacement signal compatible with 7200 Series monitors |

| Mounting Style | Standard threaded or clamp mount |

| Frequency Response | Suitable for high-speed rotating machinery |

| Compatibility | Bently Nevada 7200 Series monitoring system |

| Certifications | CE marked, RoHS compliant |

Product Applications

The 21504-000-052-10-02 probe is ideal for industrial machinery vibration monitoring and condition assessment:

-

Rotating Machinery Monitoring: Turbines, motors, compressors, and pumps to measure shaft displacement and vibration.

-

Predictive Maintenance Programs: Provides continuous data to anticipate equipment failures and reduce downtime.

-

Vibration Analysis: Works with 7200 Series systems for real-time monitoring and fault detection.

-

Industrial Automation: Ensures reliable shaft position measurements for manufacturing, chemical, and power industries.

-

Energy Sector Applications: Hydro turbines, steam turbines, and gas turbines monitoring.

-

Pulp and Paper, Mining, and Steel Industries: Monitors high-speed rotating machinery to maintain operational safety and efficiency.

Product Advantages

-

High-Precision Measurement: Accurate displacement readings for critical machinery monitoring.

-

Robust Industrial Design: Stainless steel construction and shielded cable ensure durability in harsh conditions.

-

Flexible Installation: 1.0-metre cable allows placement flexibility and easy routing.

-

Standard Mount Compatibility: 8 mm tip supports threaded or clamp mounting.

-

Low-Noise Transmission: Shielded cable reduces electromagnetic interference for clear signal acquisition.

-

Predictive Maintenance Support: Enables continuous condition monitoring for early fault detection.

-

Wide Temperature Range: Operates reliably between -40°C and +85°C.

-

Vibration Resistant: Maintains accuracy under high-speed machinery vibration.

-

System Integration: Fully compatible with Bently Nevada 7200 Series monitoring systems.

-

Ease of Installation: Designed for simple mounting and integration into existing machinery monitoring setups.

FAQ

1. What is the tip diameter of the 21504-000-052-10-02 probe?

It features an 8 mm tip diameter, which is standard for most 7200 Series mountings.

2. What is the total cable length for this probe?

The probe includes a 1.0-metre cable, providing flexible placement options.

3. Is the probe cable shielded?

Yes, the cable is shielded to minimize electromagnetic interference and ensure accurate signal transmission.

4. What type of signal does the probe generate?

It generates an analog displacement signal, compatible with 7200 Series monitoring systems.

5. What temperature range can this probe operate in?

The operating range is -40°C to +85°C, making it suitable for harsh industrial environments.

6. Can this probe be used with high-speed rotating machinery?

Yes, it is designed for high-speed turbine, motor, and pump monitoring, maintaining signal integrity under vibration.

7. How is this probe mounted on machinery?

It supports standard threaded or clamp mounting, allowing flexible installation options.

8. Is this probe compatible with Bently Nevada 7200 Series monitors?

Yes, it is fully compatible with 7200 Series monitoring systems for shaft vibration and displacement measurements.

9. Can this probe support predictive maintenance programs?

Yes, it provides continuous displacement data to enable predictive maintenance and early fault detection.

10. Does this probe maintain accuracy in environments with electrical noise?

Yes, the shielded cable design ensures accurate signal transmission even in high EMI environments.

Related Models (Same Series)

| Model | Description |

|---|---|

| 21504-000-052-10-01 | 7200 Series probe with shorter cable |

| 21504-000-052-10-03 | 7200 Series probe with longer cable |

| 21504-000-052-12-02 | Probe with 12 mm tip diameter for larger shaft clearances |

| 21504-000-052-08-05 | Flexible mount probe for tight spaces |

| 21504-000-052-10-05 | High-temperature 7200 Series probe |

| 21504-000-052-10-06 | Probe with reinforced shielding for EMI-prone areas |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL Proximitor | Proximity sensor for high-precision shaft monitoring |

| 3300 XL Accelerometer | Standard accelerometer for vibration monitoring |

| 2300 Vibration Transducer | Industrial vibration monitoring sensor |

| 3500 Series Monitoring System | Complete machinery protection and monitoring system |

| 7200 Series Wireless Sensor | Wireless monitoring for rotating machinery |

| 9500 Series Wireless Sensor | Compact sensor for predictive maintenance and vibration monitoring |

Excellent PLC

Excellent PLC