| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

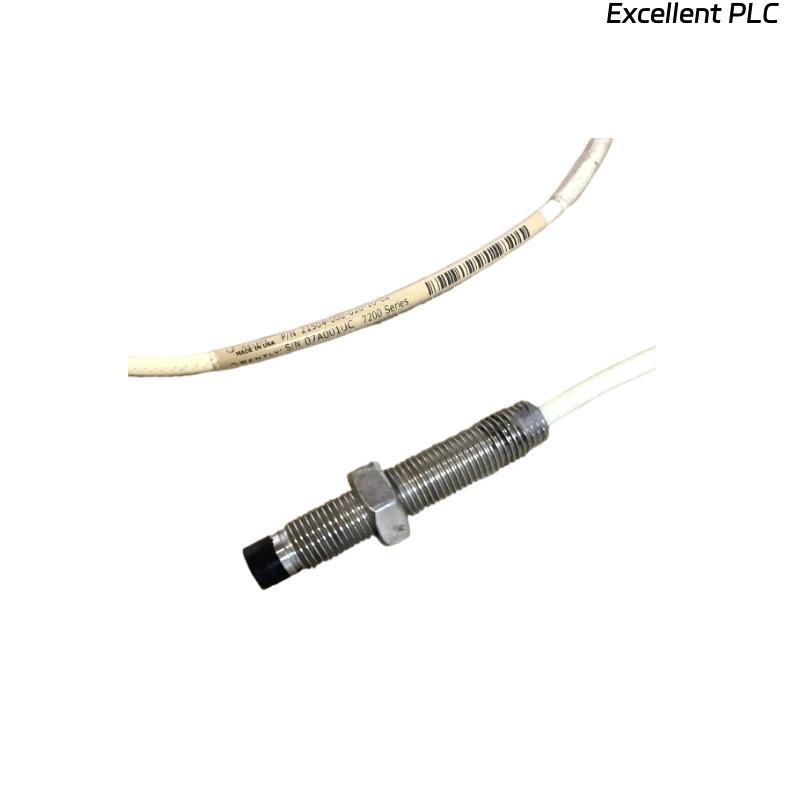

The Bently Nevada 21504-020-036-10-02 is a high-performance vibration monitoring probe from the 7200 series, designed specifically for critical industrial applications. Featuring a standard 8mm mounting and equipped with piezoelectric sensing technology, it provides real-time vibration monitoring with high sensitivity and precision. This vibration probe is ideal for measuring the vibration of machinery such as motors, pumps, compressors, and turbines. Its rugged design and advanced sensing capabilities ensure that it can handle even the harshest industrial environments, providing valuable insight into the operational health of machinery.

The 21504-020-036-10-02 probe offers high accuracy and early fault detection, helping to minimize unexpected downtime and prevent catastrophic machinery failures. Its compact form factor and simple installation make it versatile for a wide range of machinery.

Product Parameters

| Parameter | Value |

|---|---|

| Total Length | 1.0 meter |

| Weight | 0.22 kg |

| Sensing Diameter | 8 mm |

| Mounting Type | Standard mount |

| Measurement Type | Vibration sensor |

| Frequency Range | General vibration monitoring |

| Operating Temperature | -40°C to +120°C |

| Operating Principle | Piezoelectric sensor |

| Output Type | Analog (mV/g) |

| Sensitivity | 100 mV/g |

| Protection Class | IP67 |

Product Applications

The Bently Nevada 21504-020-036-10-02 probe is designed for high-precision vibration monitoring in a wide range of industrial machinery, including but not limited to:

-

Turbines: Used to detect imbalances, misalignments, or bearing wear in turbines.

-

Motors: Essential for motor condition monitoring, identifying faults like overheating or worn bearings.

-

Pumps: Monitors pumps for early signs of issues like cavitation, shaft misalignment, and unbalanced operation.

-

Compressors: Helps detect potential failures in compressors, enabling proactive maintenance to avoid breakdowns.

-

Power Generation: Crucial for ensuring reliable turbine performance and efficient power generation by continuously monitoring vibration levels.

-

Oil & Gas: Provides critical equipment health monitoring in harsh and extreme environments, such as offshore drilling rigs or refineries.

-

Industrial Machinery: Suitable for monitoring other large industrial equipment in industries like mining, chemical processing, and manufacturing.

Product Advantages

-

High Sensitivity and Accuracy: With 100 mV/g sensitivity, this probe can detect even the smallest vibrations, providing precise and accurate vibration data.

-

Durable and Reliable: Designed for harsh industrial environments, the probe has an IP67 protection rating, ensuring it is resistant to dust and water ingress, making it suitable for outdoor or tough conditions.

-

Easy Integration: It can be easily integrated into existing vibration monitoring systems for real-time data collection, making it adaptable to a variety of applications.

-

Wide Temperature Range: The probe can operate in a temperature range of -40°C to +120°C, ensuring consistent performance even in extreme conditions.

-

Cost-Effective Predictive Maintenance: By continuously monitoring vibrations, the probe enables early detection of mechanical issues, allowing for predictive maintenance that reduces the likelihood of unplanned downtime.

-

Compact Design: With a total length of 1.0 meter and a weight of 0.22 kg, the probe is compact and lightweight, making it easy to install and use in confined spaces.

-

Analog Output: The probe provides an analog mV/g output, which can be easily connected to standard vibration monitoring systems, enabling real-time vibration analysis.

-

Real-Time Fault Detection: Continuous monitoring allows for immediate identification of faults such as misalignment, imbalance, or bearing degradation, helping to avoid catastrophic failures.

-

Enhanced Operational Efficiency: By providing real-time vibration data, the probe helps operators make informed decisions, leading to better maintenance practices and improved equipment reliability.

-

Versatile Mounting Options: The standard mount design makes the probe easy to install on a variety of machines, enhancing its versatility.

FAQ

-

What is the sensitivity of the 21504-020-036-10-02 probe?

The sensitivity of the probe is 100 mV/g. -

What type of output does the probe provide?

The probe provides an analog mV/g output. -

What is the protection class of the 21504-020-036-10-02 probe?

The protection class of the probe is IP67, providing resistance to dust and water. -

What is the total length of the 21504-020-036-10-02 probe?

The total length of the probe is 1.0 meter. -

What kind of vibration monitoring is the probe suitable for?

The probe is ideal for general vibration monitoring in applications like turbines, motors, pumps, and compressors. -

Can the probe operate in extreme temperatures?

Yes, the probe operates in a temperature range from -40°C to +120°C. -

Is the probe compatible with existing vibration monitoring systems?

Yes, the probe provides analog output, making it compatible with most existing vibration monitoring systems. -

What types of machinery can the 21504-020-036-10-02 probe monitor?

The probe can be used to monitor turbines, motors, pumps, compressors, and other critical machinery. -

How does the probe help with predictive maintenance?

The probe provides continuous vibration monitoring, enabling early detection of faults and proactive maintenance to prevent costly downtime. -

What is the weight of the 21504-020-036-10-02 probe?

The probe Weight 0.22 kg.

Related Models

| Model | Description |

|---|---|

| 21504-00-08-05-02 | 8mm probe optimized for smaller machines with precision vibration monitoring. |

| 21504-00-12-06-02 | A larger 12mm probe designed for high-vibration environments. |

| 21504-00-10-10-02 | A 10mm version for high-speed machinery applications requiring detailed data. |

| 21504-00-06-10-02 | A 6mm version designed for compact spaces with high-frequency vibration analysis. |

| 21504-00-12-12-02 | A high-sensitivity probe for measuring vibration in large industrial machines. |

| 21504-00-08-14-02 | An 8mm rugged version for high-shock applications in heavy-duty machinery. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 21504-00-08-10-02 | A versatile 8mm probe for standard vibration monitoring in various industrial applications. |

| 21504-00-12-10-02 | A larger 12mm version for high-vibration environments requiring higher precision. |

| 21504-00-06-10-02 | A 6mm probe designed for compact spaces and high-precision vibration analysis. |

| 21504-00-10-12-02 | A 10mm probe for high-speed machinery and heavy-duty equipment. |

| 21504-00-12-08-02 | A high-precision 12mm probe for industrial machinery requiring detailed vibration data. |

| 21504-00-06-15-02 | A 6mm version optimized for smaller equipment with high-frequency vibration monitoring. |

Excellent PLC

Excellent PLC