| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

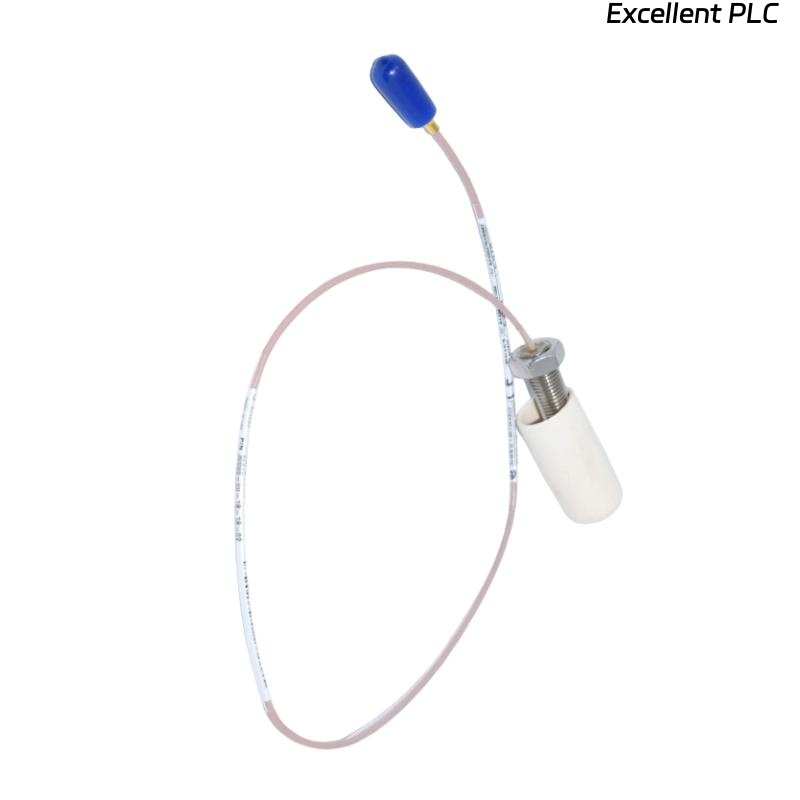

The Bently Nevada 30000-00-18-18-02 Probe Vibration Sensor is a high-precision non-contact sensor developed for vibration and displacement monitoring in critical rotating machinery. It belongs to Bently Nevada’s advanced series of vibration monitoring products, widely trusted in industries where operational reliability is paramount, such as oil & gas, petrochemical plants, and power generation facilities.

This sensor utilizes eddy-current proximity technology, enabling accurate shaft vibration and position measurements without physical contact. It is engineered to withstand harsh conditions, such as extreme temperatures, mechanical shocks, and contamination, making it ideal for long-term monitoring and preventive maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

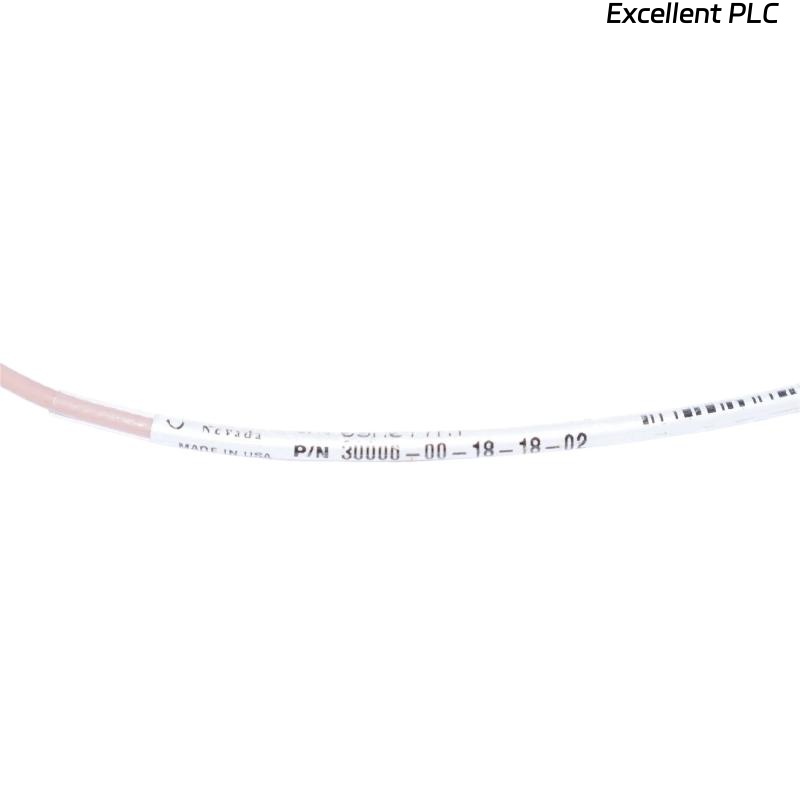

| Model Number | 30000-00-18-18-02 |

| Product Type | Probe Vibration Sensor |

| Measurement Principle | Eddy-Current Proximity Detection |

| Measurement Range | ±0.254 mm (±10 mils) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 2 mm to 4 mm |

| Frequency Response | 0 Hz to 10 kHz |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Cable Length | Optional (Factory Configurable) |

| Power Requirements | Supplied via Monitoring System |

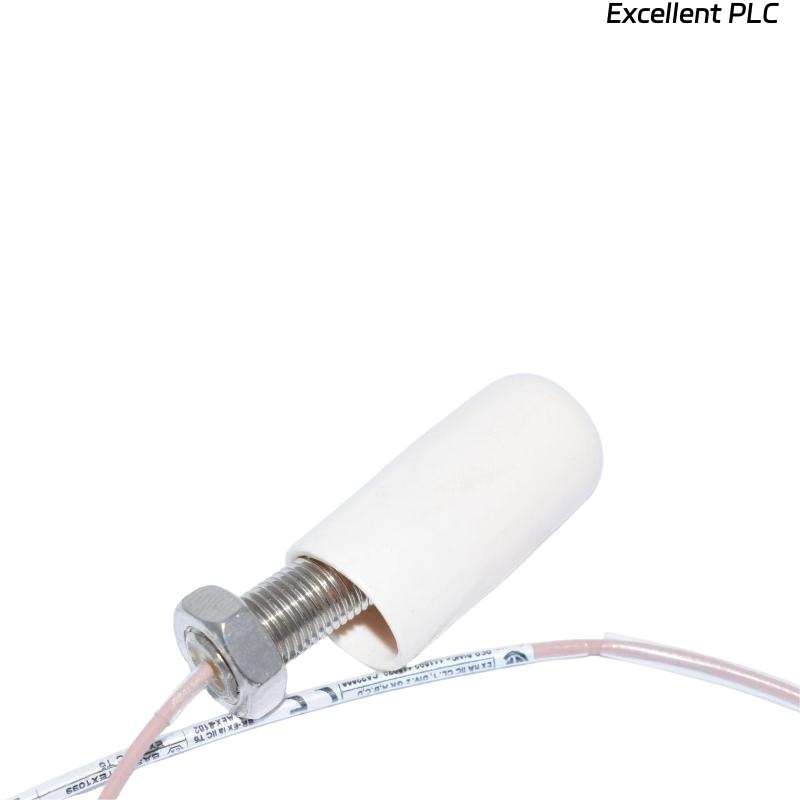

| Material | Stainless Steel Housing |

| Environmental Protection | IP65 / NEMA 4 |

| Connector Type | Compatible with Bently Nevada 3300/7200 Series |

| Cable Length | Optional |

| Shipping Weight | 3 kg |

Applications

The 30000-00-18-18-02 Probe Vibration Sensor is widely applied in critical machinery protection and condition monitoring systems. Key applications include:

-

Turbines – Monitoring shaft displacement and vibration to avoid costly downtime.

-

Compressors – Detecting imbalance or bearing wear for early intervention.

-

Generators – Ensuring operational stability and preventing mechanical failure.

-

Pumps – Detecting cavitation or misalignment conditions early.

-

Petrochemical Equipment – For continuous monitoring under hazardous conditions.

This probe plays an essential role in predictive maintenance strategies, reducing unplanned outages and extending machine life.

Advantages

-

Non-Contact Measurement – Ensures zero wear and tear on critical machine components.

-

High Accuracy & Stability – Maintains consistent performance even in severe industrial conditions.

-

Wide Operating Temperature Range – Suitable for extreme environments, from cryogenic to high-temperature applications.

-

Seamless Integration – Fully compatible with Bently Nevada’s monitoring systems like 3500 and 7200 series.

-

Customizable Cable Lengths – Allows flexible installation across various machine setups.

-

Robust Build Quality – Resistant to vibration, moisture, and contamination for long service life.

FAQ

1. What is the sensitivity of the Bently Nevada 30000-00-18-18-02 probe?

The sensitivity is 200 mV/mil (7.87 mV/μm), ensuring precise vibration readings.

2. Can this probe handle high-frequency vibration signals?

Yes, it supports a frequency response range of 0 Hz to 10 kHz, making it suitable for dynamic monitoring.

3. Is the probe compatible with the Bently Nevada 3500 Monitoring System?

Yes, it is fully compatible with the 3500 series as well as legacy 7200 systems.

4. What is the recommended linear range for this probe?

The linear range typically falls between 2 mm and 4 mm for accurate displacement readings.

5. Does the probe require external power supply?

No, it is powered through the associated monitoring system.

6. How does the probe maintain accuracy under temperature variations?

It uses advanced thermal compensation materials and design to ensure stable readings across a range of -35°C to +177°C.

7. Can the cable length be customized?

Yes, the cable length is optional and can be configured based on installation requirements.

8. What is the environmental rating of the sensor?

The probe complies with IP65 / NEMA 4 standards, providing dust and moisture protection.

9. How does the probe resist electrical noise interference?

It features shielded cables and grounding to minimize electromagnetic interference (EMI).

10. Is it possible to integrate this probe into older vibration monitoring systems?

Yes, it is designed for backward compatibility with older Bently Nevada systems.

Recommended Related Models (Same Series)

| Model Number | Description |

|---|---|

| 30000-00-08-18-02 | Probe Vibration Sensor with shorter length |

| 30000-00-12-18-02 | Mid-range probe for standard applications |

| 30000-00-20-18-02 | Extended length for deeper installations |

| 30000-00-24-18-02 | High-temperature variant |

| 30000-00-28-18-02 | Long-range probe with extended cabling |

| 30000-00-32-18-02 | Heavy-duty probe for harsh conditions |

Popular Models from Bently Nevada

| Model Number | Description |

|---|---|

| 330103-00-05-10-02-00 | Proximity Probe for 3300 series |

| 330104-00-09-10-02-00 | Standard probe for general vibration sensing |

| 3500/22M | Machine Condition Monitoring Module |

| 330130-040-00 | Extension Cable for Proximity Probes |

| 330500-02-00 | Velocity Transducer for slow-speed machines |

| 330180-91-00 | Proximitor Sensor for advanced applications |

Excellent PLC

Excellent PLC