| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

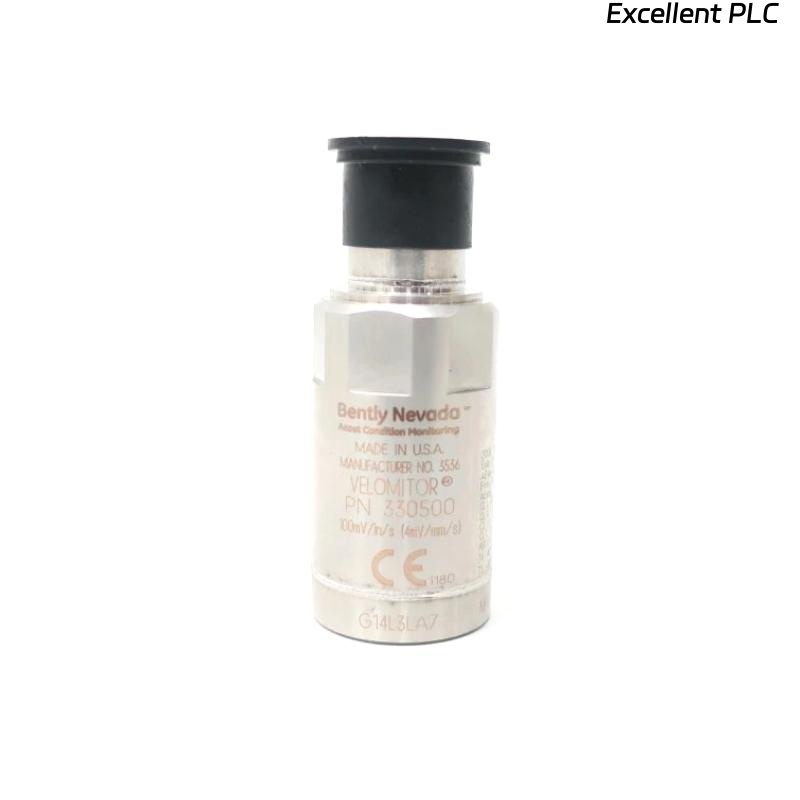

The Bently Nevada 30500-04-01 Velomitor Piezoelectric Velocity Sensor is a rugged vibration monitoring device engineered to provide accurate velocity measurements for critical rotating machinery. Using piezoelectric sensing elements, it converts mechanical vibration into a proportional electrical signal. This model is part of the trusted Velomitor family, designed to deliver reliable performance across a wide frequency spectrum, making it ideal for machinery protection and predictive maintenance.

Key Features

-

High-sensitivity piezoelectric vibration velocity sensor

-

Broad frequency response for reliable machine condition monitoring

-

Direct integration with Bently Nevada monitoring systems

-

Compact, cylindrical, and robust design for harsh environments

-

Long operational life with minimal maintenance

-

Suitable for a wide range of industrial rotating equipment

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 30500-04-01 |

| Type | Velomitor Piezoelectric Velocity Sensor |

| Sensing Principle | Piezoelectric |

| Measurement | Vibration velocity |

| Sensitivity | 100 mV/in/sec (nominal) |

| Frequency Response | 4.5 Hz to 5,000 Hz |

| Power Supply | 18–24 VDC (supplied via monitor) |

| Operating Temperature | -55 °C to +100 °C |

| Storage Temperature | -65 °C to +120 °C |

| Humidity | Up to 95% RH, non-condensing |

| Dimensions | Diameter 25.3 mm |

| Weight | 0.142 kg |

| Mounting | Stud or adhesive |

| Output | Compatible with Bently Nevada monitoring systems |

| Certification | CE, UL, CSA, industrial compliance |

Industry Applications

-

Power generation (turbines, motors, and generators)

-

Oil & gas equipment (compressors, pumps, and rotating assets)

-

Petrochemical plants and refineries

-

Metals, mining, and materials processing machinery

-

Pulp and paper manufacturing equipment

-

General industrial rotating machinery requiring vibration protection

Advantages

-

Accurate monitoring of velocity for machinery protection

-

Early detection of imbalance, looseness, misalignment, and bearing wear

-

Robust construction ensures reliability in demanding environments

-

Cost-effective condition monitoring solution

-

Easy integration with existing Bently Nevada monitoring systems

Frequently Asked Questions (FAQ)

Q1: What does the 30500-04-01 measure?

It measures vibration velocity using piezoelectric sensing.

Q2: How does it differ from the 330500 series?

While the functionality is similar, the 30500 series represents an earlier Velomitor line. The 330500 series is the newer evolution with additional configuration options.

Q3: What is the sensor’s sensitivity?

It provides a nominal output of 100 mV/in/sec.

Q4: What frequency range does it support?

4.5 Hz to 5,000 Hz.

Q5: Can it be used with standard Bently Nevada monitors?

Yes, it is designed for seamless integration.

Q6: What industries typically use this model?

It is used in oil & gas, power generation, petrochemical, pulp & paper, and heavy industries.

Q7: What is its operational temperature range?

-55 °C to +100 °C.

Q8: How is the sensor mounted?

It can be mounted using a stud or adhesive.

Q9: What makes this sensor reliable in harsh conditions?

Its rugged piezoelectric design ensures stability under vibration, temperature, and humidity stress.

Q10: Is the 30500 series still supported by Bently Nevada?

Yes, but in many cases, it is replaced by the 330500 Velomitor series for new installations.

Related Bently Nevada Models

| Model Number | Description |

|---|---|

| 30500-04-01 | Velomitor Piezoelectric Velocity Sensor |

| 330500-00-04 | Velomitor Piezoelectric Velocity Sensor |

| 330500-00-20 | Velomitor Piezoelectric Velocity Sensor |

| 330500-01-05 | Velomitor Piezoelectric Velocity Sensor |

| 330500-02-05 | Velomitor Piezoelectric Velocity Sensor |

| 330500-02-CN | Velomitor Piezoelectric Velocity Sensor |

Popular Bently Nevada Modules

| Model Number | Description |

|---|---|

| 3500/22M 288055-01 | Transient Data Interface Module |

| 3500/42M 176449-02 | Proximitor/Seismic Monitor |

| 3500/32M 149986-02 | 4-Channel Relay Module |

| 3500/33 149986-01 | 16-Channel Relay Module |

| 330104-00-05-10-02-05 | 3300 XL 8 mm Proximity Probe |

Excellent PLC

Excellent PLC