| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

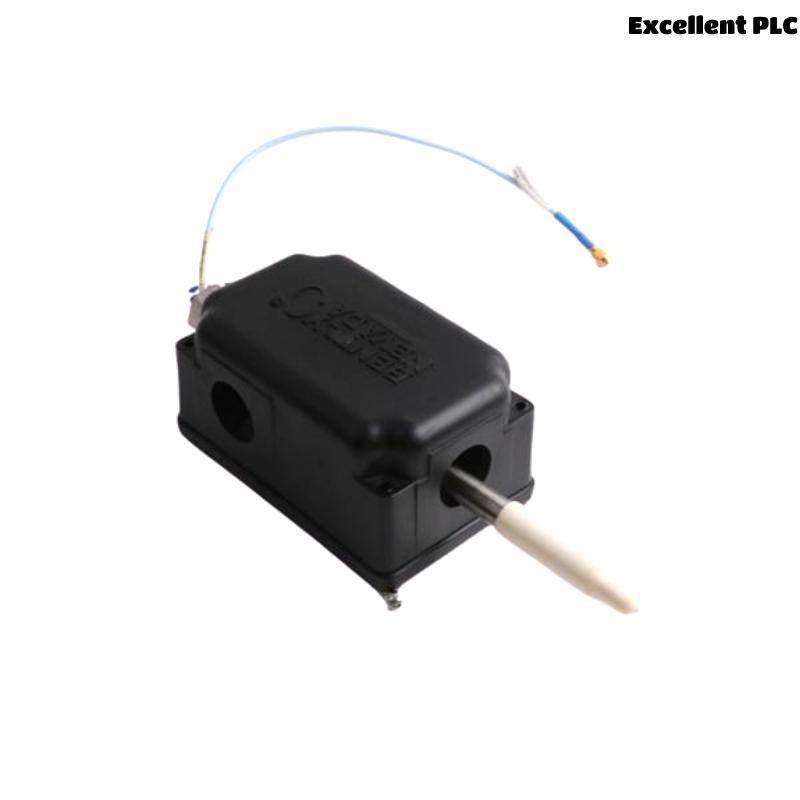

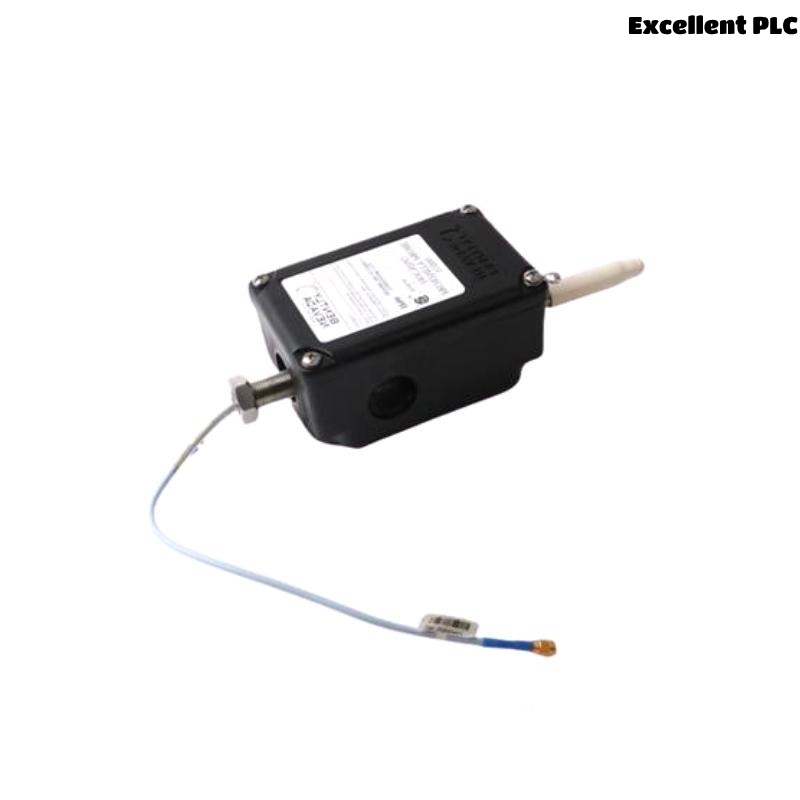

The Bently Nevada 31000-18-05-35-05-000-02 is a highly specialized proximity probe designed to deliver precise vibration and position measurements for critical rotating machinery. Engineered for demanding industrial applications, this probe embodies the rigorous standards that Bently Nevada is renowned for worldwide. Its robust design ensures reliable operation in harsh environments, making it a trusted choice in the oil & gas, power generation, and petrochemical sectors.

The model number itself reflects key specifications and configurations, signifying its place within the broader 31000 series—a line recognized for accuracy, stability, and durability.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 31000-18-05-35-05-000-02 |

| Series | 31000 Series |

| Probe Length | 18 inches |

| Sensitivity | 200 mV/mil (±5%) |

| Frequency Response | 0 to 10 kHz (±3 dB) |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Mounting Thread | 3/8-24 UNF |

| Operating Temperature | -35°C to +175°C |

| Storage Temperature | -40°C to +200°C |

| Weight | 1.2 kg |

| Dimensions | 91.4x 144.8mm |

| Power Supply | ±15 V DC (from associated Proximitor) |

| Output Signal | Voltage proportional to shaft displacement |

Note: Measurements may vary slightly based on final assembly.

Applications

The Bently Nevada 31000-18-05-35-05-000-02 proximity probe is widely applied in:

-

Monitoring shaft vibration and axial thrust in turbines, compressors, and motors

-

Detecting early signs of mechanical degradation such as misalignment or imbalance

-

Providing essential data for predictive maintenance systems

-

Supporting safety interlocks that protect expensive machinery from damage

-

Integrating with Bently Nevada’s monitoring systems for centralized diagnostics

It plays a crucial role in industries including power generation, oil & gas production, chemical manufacturing, and steel processing, where continuous condition monitoring is vital.

Product Advantages

-

High Precision: Offers stable, repeatable measurements under varying environmental conditions.

-

Robust Construction: Engineered to withstand high temperatures and vibration without signal drift.

-

Wide Frequency Range: Capable of accurately capturing a broad spectrum of machine vibration.

-

Compatibility: Seamlessly integrates with Bently Nevada Proximitor sensors and monitoring systems.

-

Ease of Installation: Designed with standard mounting threads and durable cable assemblies for straightforward installation and maintenance.

-

Long Service Life: Built with high-quality materials, minimizing downtime and replacement costs.

-

Trusted Brand: Supported by Bently Nevada’s decades of innovation and field-proven reliability.

FAQs (10 Questions & Answers)

Q1: What makes this probe suitable for high-temperature environments?

A1: Its use of PPS probe tip material and high-temperature-rated cable allow it to operate reliably up to +175°C.

Q2: How does the probe measure shaft displacement?

A2: It senses changes in the eddy current field as the shaft moves, converting them into a proportional voltage signal.

Q3: Is it compatible with all Proximitor modules?

A3: Yes, it’s specifically designed to work with compatible Bently Nevada Proximitor modules, ensuring precise signal conditioning.

Q4: What industries commonly use this probe?

A4: Oil & gas, power generation, chemical processing, paper mills, and steel production.

Q5: Can the probe cable be extended beyond 5 meters?

A5: Cable length is factory configured to maintain signal integrity; custom lengths should be ordered from the manufacturer.

Q6: How does it help prevent machinery failure?

A6: By providing real-time vibration and position data, it enables early detection of mechanical issues before they lead to costly downtime.

Q7: What mounting options are available?

A7: It features a 3/8-24 UNF mounting thread, allowing installation in standard probe mounting brackets or directly into threaded holes.

Q8: Is calibration required?

A8: Factory calibration ensures accuracy, but periodic system calibration is recommended for long-term reliability.

Q9: How long is its operational lifespan?

A9: With proper installation and maintenance, service life can exceed 5 years.

Q10: Does it support dynamic vibration monitoring?

A10: Yes, its frequency response up to 10 kHz captures both static displacement and dynamic vibration.

Recommended Related Models (Same Series or Similar)

| Model Number | Probe Length | Cable Length | Sensitivity | Temperature Range |

|---|---|---|---|---|

| 31000-12-05-25-05-000-02 | 12 in | 5 m | 200 mV/mil | -35°C to +175°C |

| 31000-24-05-25-05-000-02 | 24 in | 5 m | 200 mV/mil | -35°C to +175°C |

| 31000-18-10-25-05-000-02 | 18 in | 10 m | 200 mV/mil | -35°C to +175°C |

| 31000-18-05-45-05-000-02 | 18 in | 5 m | 300 mV/mil | -35°C to +175°C |

| 31000-24-10-35-05-000-02 | 24 in | 10 m | 200 mV/mil | -35°C to +175°C |

| 31000-12-05-45-05-000-02 | 12 in | 5 m | 300 mV/mil | -35°C to +175°C |

Other Popular Bently Nevada Models

| Model Number | Type | Sensitivity / Key Spec | Typical Application |

|---|---|---|---|

| 330103-00-05-10-02-00 | Proximity Probe | 200 mV/mil | Turbine vibration monitoring |

| 330104-00-05-10-02-00 | Extension Cable | 5 m | Connects probe to proximitor module |

| 330130-040-00-00 | Proximitor Sensor | ±15 V DC supply | Signal conditioning for probes |

| 330180-91-05 | Velomitor Sensor | 100 mV/in/sec | Velocity measurement in pumps/compressors |

| 3500/22M | Transient Data Interface | Modbus RTU & TCP | Real-time machinery protection |

| 3500/42M | Proximitor / Seismic Monitor | Dual channel | Monitors vibration and axial position |

Excellent PLC

Excellent PLC