| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

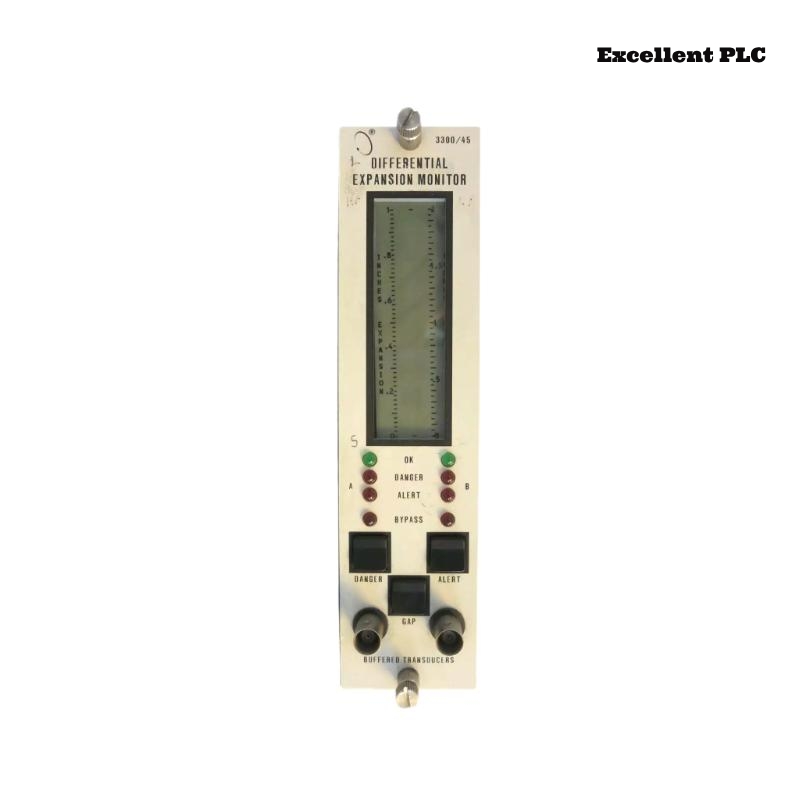

The Bently Nevada 3300/45-03-02-00-00 Dual Differential Expansion Monitor is a specialized and advanced equipment designed to monitor the differential expansion between two key points in rotating machinery such as turbines and compressors. It is part of the trusted 3300 Series from Bently Nevada, known for offering precise and reliable measurements that are critical for machinery health monitoring and predictive maintenance.

This model is designed to capture data on differential expansion and provide valuable insights into the condition of the rotating equipment. The 3300/45-03-02-00-00 utilizes advanced sensors and algorithms to provide highly accurate and real-time data, helping operators prevent potential failures and ensure the longevity and efficiency of their machines. It is widely used in industries such as power generation, oil and gas, petrochemical, and large-scale manufacturing, where the integrity of rotating machinery is crucial for operational safety and efficiency.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 3300/45-03-02-00-00 |

| Product Type | Dual Differential Expansion Monitor |

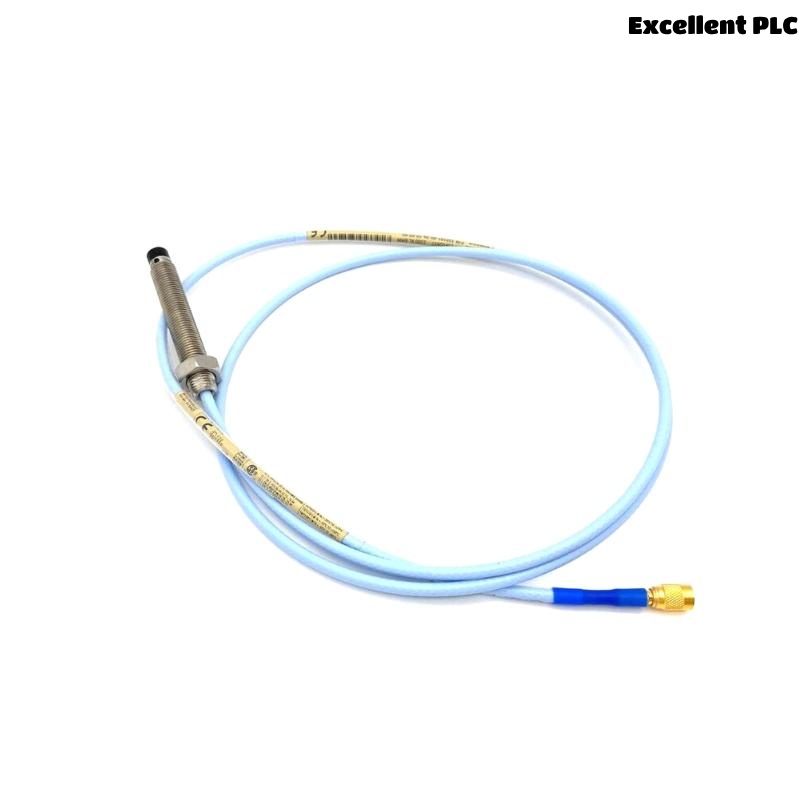

| Input Type | Differential Expansion Transducers |

| Measurement Type | Differential Expansion |

| Output | 4-20 mA (two analog output channels) |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

| Response Time | < 100 ms |

| Mounting | Wall or panel mounting |

| Protection Features | Overvoltage, short-circuit, reverse polarity protection |

| Display Type | LCD (optional) |

| Certification | CE, UL, RoHS, ATEX (optional) |

Applications:

The Bently Nevada 3300/45-03-02-00-00 Dual Differential Expansion Monitor is designed for use in a variety of applications where critical rotating machinery requires accurate condition monitoring. The following are some of its most common applications:

-

Turbomachinery Monitoring: It is particularly effective in monitoring steam turbines, gas turbines, and compressors to prevent mechanical failures due to excessive differential expansion.

-

Power Generation: In power plants, this monitor ensures that turbines and other machinery operate within safe limits, avoiding downtime and costly repairs.

-

Oil & Gas: The system is essential for maintaining drilling rigs, compressors, and pumps, which are critical for continuous operations in the oil and gas industry.

-

Refining and Chemical Processing: In refineries, the 3300/45-03-02-00-00 helps monitor equipment like pumps and motors to optimize maintenance and ensure safe operations.

-

Petrochemical Plants: The monitor is widely used in petrochemical plants where differential expansion monitoring is vital to prevent operational hazards and equipment failure.

-

Industrial Automation: Used to monitor critical machinery in large-scale industrial automation systems, it helps identify issues before they lead to catastrophic failures.

-

Critical Process Systems: Ideal for monitoring the machinery in applications that require high reliability and safety, such as food processing, pharmaceuticals, and automotive production lines.

-

Vibration and Expansion Monitoring Systems: Often used as part of a broader machinery health monitoring system that tracks various operational parameters, including vibration, temperature, and expansion.

Product Advantages:

-

High Precision and Accuracy: The 3300/45-03-02-00-00 provides precise differential expansion measurements, ensuring that machinery operates within safe and optimal limits.

-

Real-Time Monitoring: The monitor provides real-time feedback on the health of machinery, enabling operators to take corrective actions before any damage occurs.

-

Durable and Reliable: Built to withstand harsh industrial environments, the 3300/45-03-02-00-00 is rugged and reliable, ensuring long-term use without frequent failures.

-

Advanced Protection Features: Includes overvoltage, short-circuit, and reverse polarity protection to safeguard against electrical issues in challenging environments.

-

Wide Temperature Range: Operating in a broad temperature range from -40°C to +70°C, the monitor can be used in various industrial settings, including extreme environments.

-

Cost Savings through Predictive Maintenance: By identifying potential issues early, the monitor reduces the need for costly unscheduled maintenance and downtime.

-

Easy Installation and Integration: The compact design and easy-to-use mounting options (wall or panel mounting) make installation straightforward and cost-effective.

-

Improved Safety: Real-time monitoring of differential expansion reduces the risk of catastrophic machinery failures, which could lead to safety hazards for personnel and equipment.

-

Optional LCD Display: The optional LCD display allows for easy visual diagnostics and monitoring without requiring additional software or systems.

-

Versatile for Multiple Applications: Whether in power generation, refining, or industrial manufacturing, the monitor is versatile and adapts to a range of machinery health monitoring needs.

Latest News Titles:

-

“Bently Nevada Launches the 3300/45-03-02-00-00 for Real-Time Differential Expansion Monitoring”

-

“Bently Nevada’s Latest Innovation: 3300/45-03-02-00-00 Dual Differential Expansion Monitor Ensures Safe Turbine Operations”

-

“Revolutionizing Industrial Safety with the 3300/45-03-02-00-00 Differential Expansion Monitor”

-

“How the Bently Nevada 3300/45-03-02-00-00 Reduces Unplanned Downtime in Power Plants”

-

“Bently Nevada Expands Machinery Health Monitoring Capabilities with New 3300/45-03-02-00-00 Model”

-

“Bently Nevada’s 3300/45-03-02-00-00 Keeps Oil and Gas Operations Running Smoothly”

-

“New Bently Nevada Monitor Protects Critical Industrial Equipment from Differential Expansion Failures”

-

“The 3300/45-03-02-00-00 Monitor: Preventing Failures and Enhancing Maintenance in Chemical Processing Plants”

FAQ:

-

What does the 3300/45-03-02-00-00 monitor?

-

The 3300/45-03-02-00-00 monitors the differential expansion between two points in rotating machinery, such as turbines or compressors, to ensure they remain within safe operational limits.

-

-

How does the 3300/45-03-02-00-00 provide output?

-

The monitor provides a 4-20 mA output signal for each of its two channels, which can be used to send data to other monitoring or control systems.

-

-

What is the operating temperature range for this product?

-

The 3300/45-03-02-00-00 operates within a temperature range of -40°C to +70°C, making it suitable for diverse industrial environments.

-

-

Can the 3300/45-03-02-00-00 be used in hazardous environments?

-

Yes, with certifications such as CE, UL, and RoHS, the 3300/45-03-02-00-00 is designed to meet the standards for use in potentially hazardous environments.

-

-

What type of mounting options are available for this module?

-

The 3300/45-03-02-00-00 can be wall-mounted or panel-mounted for flexible installation in various industrial setups.

-

-

Is the 3300/45-03-02-00-00 compatible with other Bently Nevada products?

-

Yes, the monitor integrates seamlessly with other Bently Nevada machinery health monitoring systems for comprehensive condition monitoring.

-

-

What happens if the differential expansion exceeds safe limits?

-

The monitor will provide immediate feedback, enabling operators to take corrective action before damage to the machinery occurs.

-

-

Does the 3300/45-03-02-00-00 have a display?

-

An optional LCD display is available for this model, allowing operators to visually monitor real-time data and diagnostics.

-

-

What protection features are built into the 3300/45-03-02-00-00?

-

The monitor includes overvoltage, short-circuit, and reverse polarity protection to ensure safe operation under harsh conditions.

-

-

What industries typically use the 3300/45-03-02-00-00?

-

This model is widely used in industries such as power generation, oil and gas, petrochemical, and refining, where machinery monitoring is critical to operational safety.

-

Related Models of Bently Nevada 3300/45-03-02-00-00:

| Model | Description | Measurement Type | Channels |

|---|---|---|---|

| Bently Nevada 3300/45-03-02-00-01 | Dual Differential Expansion Monitor with LCD Display | Differential Expansion | 2 |

| Bently Nevada 3300/45-03-03-00-00 | High-Sensitivity Differential Expansion Monitor | Differential Expansion | 2 |

| Bently Nevada 3300/20-12-01-01 | Dual Thrust Position Monitor | Thrust Position | 2 |

| Bently Nevada 3300/25-01-02-00 | Vibration & Expansion Measurement Module | Vibration & Expansion | 2 |

| Bently Nevada 3300/26-03-02-00 | Dual Channel Proximity Monitor | Proximity | 2 |

| Bently Nevada 3300/35-02-00-00 | Dual Radial Vibration Monitor | Radial Vibration | 2 |

| Bently Nevada 3300/36-01-01-00 | Axial Position Monitor | Axial Position | 1 |

| Bently Nevada 3300/50-01-00-00 | Dual Acceleration Monitor | Acceleration | 2 |

Popular Models from Bently Nevada:

| Model | Description | Measurement Type | Channels |

|---|---|---|---|

| Bently Nevada 3500/22M | Vibration Monitoring System | Vibration | 8 |

| Bently Nevada 3500/42M | Keyphasor™ Speed Sensor | Speed Measurement | 1 |

| Bently Nevada 3500/53 | Tachometer / Speed Monitor | Speed Measurement | 2 |

| Bently Nevada 3500/71 | Machine Monitor for Large Equipment | Vibration, Expansion | 12 |

| Bently Nevada 3500/72 | Expansion and Vibration Monitoring System | Expansion & Vibration | 8 |

| Bently Nevada 3500/90 | Machinery Protection System | Vibration, Expansion | 6 |

| Bently Nevada 3300/16 | Vibration Monitoring System | Vibration | 4 |

| Bently Nevada 3300/25 | Vibration and Expansion Measurement System | Vibration & Expansion | 2 |

Excellent PLC

Excellent PLC