| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

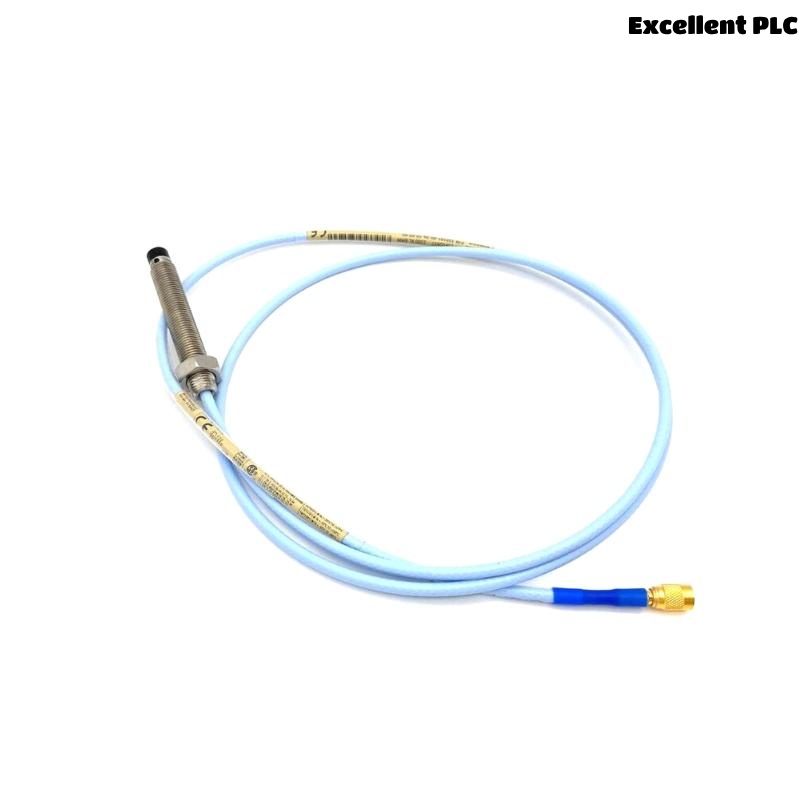

The Bently Nevada 3300/46 Differential Expansion Monitor is a specialized device engineered to measure the differential expansion between a machine’s rotor and its casing. This measurement is crucial for large rotating machinery, such as turbines, compressors, and generators, where thermal growth and mechanical movements can significantly impact operational integrity. By employing two proximity probes that observe ramp surfaces on the rotor, the 3300/46 provides a comprehensive assessment of both the magnitude and direction of differential expansion, ensuring enhanced machinery protection and performance.

Product Specifications:

| Parameter | Description |

|---|---|

| Measurement Range | 0.5-0-0.5 inches |

| Transducer Input | 35 mm |

| Alarm Relays | Configurable; options include no relays |

| Display | LCD indicating magnitude and direction of differential expansion |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

-

Differential Expansion Monitoring: Essential for large rotating machines where traditional measurement methods may be inadequate.

-

Mechanical Issue Detection: Facilitates early identification of misalignment, thermal growth, or other mechanical anomalies.

-

Equipment Protection: Safeguards critical machinery from potential damage, thereby reducing downtime and maintenance costs.

Advantages:

-

Enhanced Monitoring Range: Utilizes ramp surfaces on the rotor, allowing for increased monitoring ranges with standard transducers.

-

Flexible Installation: The ability to use ramp surface targets provides added flexibility in choosing transducer mounting locations, especially when conventional methods are not feasible.

-

Comprehensive Display: The LCD provides clear indications of both the magnitude and direction of differential expansion, aiding in prompt decision-making.

-

Configurable Alarms: Offers four alarm setpoints (two over and two under) to alert operators to potential issues, enhancing proactive maintenance strategies.

Recent Product News:

-

“Bently Nevada 3300/46 Enhances Machinery Protection with Advanced Monitoring Capabilities”

-

“Innovative Expansion Monitoring: A Deep Dive into Bently Nevada’s 3300/46 System”

-

“Maximizing Rotating Machinery Efficiency Using Bently Nevada’s 3300/46 Monitor”

Bently Nevada 3300/46 Differential Expansion Monitor – FAQs

-

What does the Bently Nevada 3300/46 Differential Expansion Monitor do?

The 3300/46 Differential Expansion Monitor is designed to measure the differential expansion between the rotor and casing in rotating machinery. This expansion occurs due to thermal growth or other mechanical movements. The monitor uses proximity probes to detect changes in the position of the rotor relative to the machine casing, which is critical for monitoring the health of the equipment and preventing damage.

-

Why is differential expansion important to monitor in rotating equipment?

Differential expansion is crucial because, if not properly managed, it can cause misalignment, excessive wear, and even catastrophic failure in machinery. By measuring the differential expansion, the monitor ensures that thermal growth is accounted for, and the equipment can function within safe operational limits. This is especially important for turbines, compressors, and generators, where the expansion of parts can be substantial during operation.

-

How does the Bently Nevada 3300/46 monitor the differential expansion?

The 3300/46 uses two proximity probes that are installed on the rotor and casing. These probes measure the distance between the rotor and the casing at specific points. The device continuously monitors and provides real-time data on any changes in this distance, indicating any expansion or contraction. The data is then displayed and can trigger alarms if the expansion exceeds preset limits.

-

What types of equipment can benefit from using the 3300/46 Differential Expansion Monitor?

The 3300/46 is typically used in large rotating machinery like turbines, compressors, and generators. These types of equipment experience significant thermal growth and mechanical stresses during operation, making them ideal candidates for differential expansion monitoring. The monitor ensures that the machinery is protected from potential damage due to excessive expansion, misalignment, or other operational issues.

-

Can the 3300/46 be integrated with existing monitoring systems?

Yes, the 3300/46 Differential Expansion Monitor is designed to be compatible with other Bently Nevada monitoring equipment, especially within the 3300 series. It can be easily integrated into an existing condition monitoring system, allowing operators to combine its data with other measurements such as vibration, temperature, and pressure for a comprehensive view of machinery health.

-

What kind of alarms and notifications does the 3300/46 provide?

The 3300/46 comes with configurable alarm setpoints. It can trigger up to four alarm conditions—two for over-expansion and two for under-expansion—based on the differential expansion readings. These alarms help operators take corrective actions before the issue escalates, preventing potential machinery damage or unplanned downtime.

-

What is the benefit of using the 3300/46 compared to traditional expansion measurement methods?

Traditional expansion measurement methods, such as using thermocouples or other indirect measurement devices, can be less accurate or difficult to implement in certain machines. The 3300/46 uses proximity probes, which directly measure the rotor-to-casing distance, providing more accurate and real-time data. This leads to better protection for the equipment and allows for more effective predictive maintenance strategies.

-

What are the key features of the 3300/46 Differential Expansion Monitor?

Key features of the 3300/46 include:

-

High accuracy in measuring rotor-to-casing differential expansion.

-

Easy integration with other Bently Nevada monitoring equipment.

-

Flexible configuration of alarm setpoints.

-

Real-time monitoring and data display.

-

Compatibility with large, complex rotating machinery such as turbines and compressors.

-

-

Is the 3300/46 suitable for harsh industrial environments?

Yes, the 3300/46 is built to withstand demanding industrial environments. It is designed for use in harsh conditions where large rotating machinery operates, such as power plants, oil refineries, and manufacturing plants. The device is rugged and durable, ensuring reliable performance even in environments with high vibration, temperature fluctuations, and other challenging conditions.

-

How do I install and configure the Bently Nevada 3300/46 Differential Expansion Monitor?

Installation and configuration of the 3300/46 are straightforward, especially when replacing or upgrading an existing system. Detailed instructions are provided in the product manual, and Bently Nevada offers technical support to assist with setup. Installation generally involves mounting the proximity probes, connecting the monitor to the system, and configuring alarm setpoints based on the specific needs of the equipment being monitored. It is recommended that installation be performed by trained professionals to ensure optimal performance.

Related Models in the Same Series:

| Model | Description | Measurement Type | Channels |

|---|---|---|---|

| Bently Nevada 3300/45 | Differential Expansion Monitor | Differential Expansion | 2 |

| Bently Nevada 3300/47 | Vibration Monitoring System | Vibration Measurement | 2 |

| Bently Nevada 3300/48 | Position Monitoring System | Position Measurement | 2 |

| Bently Nevada 3300/50 | Velocity Measurement System | Velocity Measurement | 2 |

| Bently Nevada 3300/55 | Thrust Position Monitoring System | Thrust Position | 2 |

| Bently Nevada 3300/60 | Temperature Monitoring System | Temperature Measurement | 2 |

| Bently Nevada 3300/65 | Speed Monitoring System | Speed Measurement | 2 |

| Bently Nevada 3300/70 | Phase Reference Monitoring System | Phase Measurement | 2 |

Popular Models from Bently Nevada:

| Model | Description | Measurement Type | Channels |

|---|---|---|---|

| Bently Nevada 3300/05 | Vibration Sensor | Vibration Measurement | 1 |

| Bently Nevada 3300/12 | Proximity Sensor | Proximity Measurement | 1 |

| Bently Nevada 3300/13 | Proximity Transducer | Proximity Measurement | 1 |

| Bently Nevada 3300/20 | Vibration Transducer | Vibration Measurement | 1 |

| Bently Nevada 3300/30 | Accelerometer | Acceleration Measurement | 1 |

| Bently Nevada 3300/35 | Accelerometer and Displacement Sensor | Acceleration & Displacement | 1 |

| Bently Nevada 3300/40 | Temperature Sensor | Temperature Measurement | 1 |

| Bently Nevada 3300/55 | Thrust Measurement System | Thrust Measurement | 2 |

Excellent PLC

Excellent PLC