| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

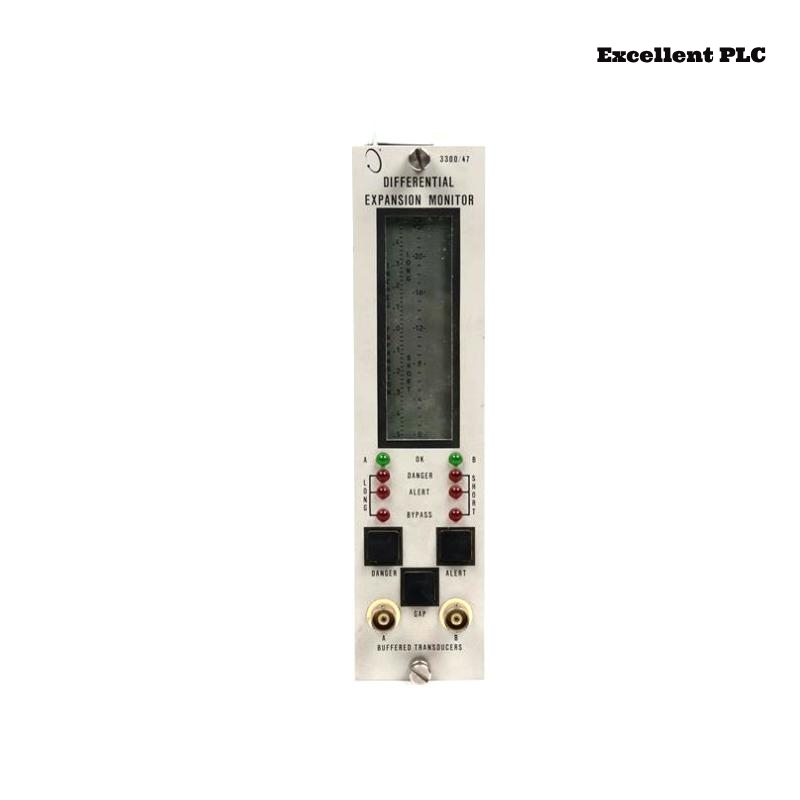

The Bently Nevada 3300/47 Complementary Input Differential Expansion Monitor is an advanced vibration monitoring module designed for industrial rotating machinery. This monitor is a part of the Bently Nevada 3300 series, which is widely used for condition monitoring and predictive maintenance. The 3300/47 module is specifically designed to measure differential expansion in turbines, helping to prevent potential mechanical failures caused by thermal expansion variations.

By utilizing high-precision proximity probes, this monitor accurately detects the axial displacement of rotating components relative to a fixed reference point, ensuring machinery remains within safe operational limits. The 3300/47 monitor is engineered for reliability and accuracy, making it an essential component in power plants, refineries, and other heavy industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 3300/47 |

| Series | 3300 Series |

| Measurement Type | Differential Expansion Monitoring |

| Input Type | Two complementary input signals |

| Proximity Probe Compatibility | Bently Nevada 3300 XL Probes |

| Sensitivity | Configurable based on application |

| Power Supply | 24V DC |

| Alarm Setpoints | Adjustable for Warning and Danger Levels |

| Output Signal | 4-20mA, Relay Output |

| Operating Temperature | -30°C to +85°C |

| Humidity Range | 5% to 95% Non-condensing |

| Communication Interface | Compatible with Bently Nevada 3500 System |

| Mounting Type | Rack-mounted in 3300 System |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/47 monitor is widely used in industries that require continuous monitoring of machine conditions. Some of its key application areas include:

-

Power Generation Plants – Monitoring steam turbines for excessive thermal expansion.

-

Oil & Gas Refineries – Ensuring safe operations of compressors and pumps.

-

Petrochemical Plants – Preventing mechanical damage in large-scale rotating equipment.

-

Steel & Metal Processing – Monitoring heavy-duty industrial machinery.

-

Pulp & Paper Industry – Ensuring reliability in continuous manufacturing processes.

By implementing the 3300/47 Differential Expansion Monitor, industries can significantly reduce unplanned downtime and maintenance costs while enhancing overall operational safety.

Product Advantages

-

High Precision Monitoring – Provides accurate differential expansion measurements to prevent equipment failures.

-

Reliable Alarm System – Adjustable warning and danger levels for proactive maintenance.

-

Wide Compatibility – Works seamlessly with Bently Nevada 3300 XL Proximity Probes and 3500 systems.

-

Enhanced Safety – Helps mitigate risks associated with thermal expansion and misalignment.

-

User-Friendly Interface – Simplifies configuration and monitoring processes.

-

Rugged Design – Built to withstand harsh industrial environments.

-

Reduced Downtime – Early detection of potential issues prevents unexpected breakdowns.

-

Industry Standard Compliance – Meets global safety and reliability standards.

Latest News Titles

-

“Bently Nevada 3300/47: Enhancing Turbine Safety Through Advanced Monitoring”

-

“The Role of Differential Expansion Monitors in Modern Power Plants”

-

“Bently Nevada 3300 Series: A Benchmark in Machinery Protection”

-

“How Predictive Maintenance with Bently Nevada 3300/47 Reduces Costs”

-

“Latest Upgrades in the Bently Nevada 3300 Monitoring System”

-

“Preventing Catastrophic Failures: The Importance of Differential Expansion Monitoring”

-

“Bently Nevada’s 3300/47: Optimizing Efficiency in Industrial Rotating Equipment”

-

“How the 3300/47 Monitor Improves Machinery Reliability in Oil & Gas”

FAQ (Frequently Asked Questions)

-

What is the primary function of the Bently Nevada 3300/47 monitor?

The primary function is to measure differential expansion in rotating machinery, helping to detect misalignment due to thermal expansion. -

What types of sensors are compatible with the 3300/47 module?

It is compatible with Bently Nevada 3300 XL Proximity Probes for accurate displacement measurement. -

Can the 3300/47 monitor be integrated into an existing Bently Nevada 3500 system?

Yes, it is fully compatible with the Bently Nevada 3500 system for centralized monitoring. -

What industries commonly use the Bently Nevada 3300/47 monitor?

Power plants, oil & gas refineries, petrochemical industries, and metal processing plants. -

Does the 3300/47 monitor support remote diagnostics?

Yes, when integrated with compatible monitoring systems, it allows remote diagnostics and data analysis. -

How is the alarm system configured?

Users can set warning and danger levels based on operational thresholds. -

What is the typical response time of the monitor?

The response time is within milliseconds, ensuring real-time protection. -

What is the power requirement for the Bently Nevada 3300/47?

It operates on a 24V DC power supply. -

Can this monitor withstand extreme temperatures?

Yes, it operates reliably within a temperature range of -30°C to +85°C. -

Is the 3300/47 monitor suitable for hazardous environments?

Yes, it meets industry safety standards and can be used in hazardous areas with proper certification.

Recommended Related Models

| Model | Description |

|---|---|

| Bently Nevada 3300/46 | Dual-channel vibration monitor |

| Bently Nevada 3300/50 | Dual-channel temperature monitor |

| Bently Nevada 3300/65 | Velocity and acceleration monitoring |

| Bently Nevada 3300/20 | Protective monitoring for rotating machinery |

| Bently Nevada 3300/14 | Proximity probe signal conditioning module |

| Bently Nevada 3300/35 | Multi-channel machine condition monitor |

| Bently Nevada 3300/60 | Advanced vibration monitoring system |

| Bently Nevada 3300/16 | Turbine supervisory monitoring system |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| Bently Nevada 3500/42M | Proximity and seismic monitor |

| Bently Nevada 3500/93 | Display monitor for machine protection |

| Bently Nevada 3500/25 | Enhanced temperature monitor |

| Bently Nevada 1900/65A | Portable machine condition monitor |

| Bently Nevada 990 | Compact vibration monitoring module |

| Bently Nevada 3701/55 | Machinery protection system |

| Bently Nevada ADRE 408 | Data acquisition system for diagnostics |

| Bently Nevada 2300/20 | Condition monitoring for critical assets |

Excellent PLC

Excellent PLC