| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

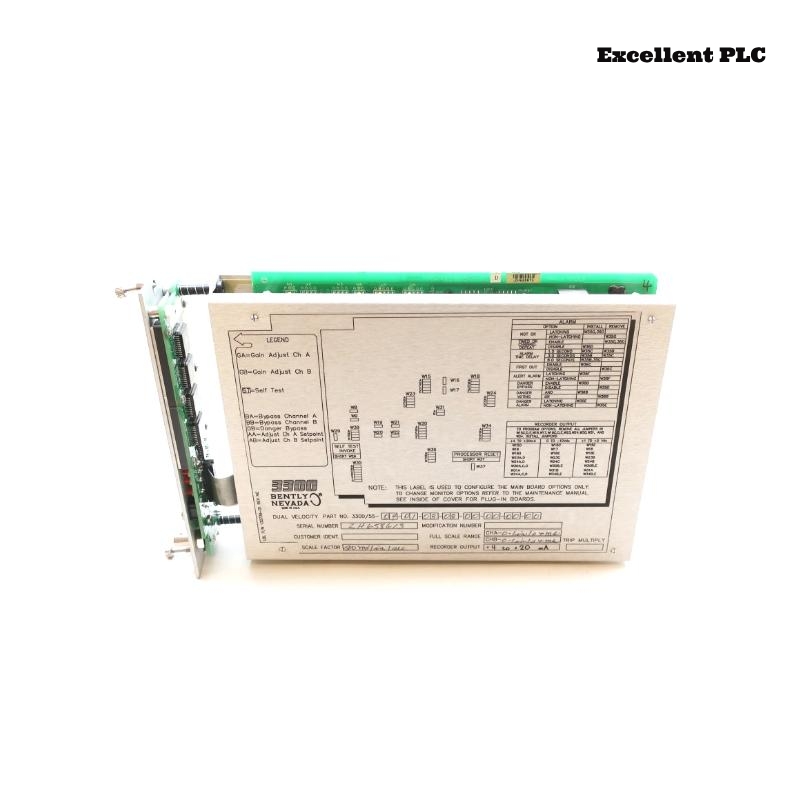

The Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor is a sophisticated device engineered for continuous, real-time monitoring of vibration velocity in rotating machinery. As a pivotal component of the renowned 3300 series, this monitor offers dual-channel inputs, allowing simultaneous assessment of two independent vibration signals. It is compatible with Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers, eliminating the need for additional interface modules. This flexibility ensures accurate detection of mechanical issues such as imbalance, misalignment, and looseness, facilitating proactive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 3300/55-04-01-08-08-00-00-00-00 |

| Measurement Type | Dual-channel velocity monitoring |

| Input Types | Velomitor® transducers, HTVS, Velocity Seismoprobe® transducers |

| Sensitivity Options | 500 mV/in/s, 145 mV/in/s, 100 mV/in/s (jumper-programmable) |

| Frequency Response | 3 Hz to 10,000 Hz (-3 dB nominal) |

| Alarm Setpoints | Digitally adjustable from 0% to 100% of full-scale |

| Output Options | +4 to +20 mA, 0 to -10 Vdc, +1 to +5 Vdc |

| Power Consumption | Nominal 1.5 Watts |

| Operating Temperature | 0°C to +65°C (32°F to 150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity | Up to 95%, non-condensing |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The 3300/55 Dual Velocity Monitor is utilized across various industries for the protection and maintenance of critical rotating equipment:

-

Power Generation: Monitoring turbines and generators to detect early signs of vibration-related issues.

-

Oil & Gas: Ensuring the integrity of compressors and pumps in upstream and downstream operations.

-

Petrochemical: Overseeing the performance of rotating machinery in processing plants.

-

Manufacturing: Maintaining the health of motors, fans, and other rotating equipment on production lines.

-

Mining: Supervising crushers, conveyors, and other heavy-duty machinery for vibration anomalies.

Advantages

-

Dual-Channel Monitoring: Enables simultaneous assessment of two separate vibration signals, enhancing diagnostic capabilities.

-

Wide Frequency Response: Covers a broad spectrum, allowing detection of various vibration issues.

-

Flexible Sensitivity Settings: Accommodates different machinery types and operational conditions.

-

User-Selectable Filters: High- and low-pass filter options can be easily configured via plug-in jumpers.

-

Comprehensive Output Options: Provides multiple output formats for integration with diverse control systems.

-

Robust Alarm System: Digitally adjustable alarm setpoints facilitate timely alerts for preventive action.

-

Environmental Resilience: Designed to operate effectively across a range of temperatures and humidity levels.

Latest News Headlines

-

“Bently Nevada 3300/55 Enhances Predictive Maintenance in Power Plants”

-

“Advancements in Vibration Monitoring: Spotlight on Bently Nevada’s Dual Velocity Monitor”

-

“Oil & Gas Industry Adopts Bently Nevada 3300/55 for Improved Equipment Reliability”

-

“Case Study: Reducing Downtime with Bently Nevada’s 3300/55 Monitor”

-

“Integrating Bently Nevada 3300/55 into Modern Industrial IoT Systems”

Frequently Asked Questions (FAQ)

-

What is the primary function of the Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor?

-

It provides continuous, real-time monitoring of vibration velocity in rotating machinery to detect and diagnose mechanical issues early.

-

-

Which transducers are compatible with this monitor?

-

It is compatible with Bently Nevada Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers.

-

-

What sensitivity options are available?

-

The monitor offers jumper-programmable sensitivity settings of 500 mV/in/s, 145 mV/in/s, and 100 mV/in/s.

-

-

What is the frequency response range of the monitor?

-

For Velocity Seismoprobe® transducers, the range is 3 Hz to 10,000 Hz (-3 dB nominal). For HTVS and Velomitor® transducers, it is 3 Hz to 3,000 Hz (-3 dB nominal).

-

-

How are alarm setpoints configured?

-

Both Alert and Danger alarms are digitally adjustable from 0% to 100% of full-scale, allowing customization based on specific monitoring requirements.

-

-

What output options does the monitor provide?

-

It offers recorder outputs that are user-programmable for +4 to +20 mA, 0 to -10 Vdc, or +1 to +5 Vdc, proportional to the programmed monitor full-scale.

-

-

Is the monitor suitable for harsh industrial environments?

-

Yes, it operates effectively within a temperature range of 0°C to +65°C (+32°F to +150°F) and can withstand relative humidity up to 95%, non-condensing.

-

-

What are the dimensions and weight of the monitor?

-

The monitor occupies one rack position and weighs 1 kg.

-

-

Can the monitor integrate with existing control systems?

-

Yes, its comprehensive output options facilitate seamless integration with various control and automation systems.

-

-

What maintenance is required for optimal performance?

-

Regular calibration checks and visual inspections are recommended to ensure the monitor functions correctly and provides accurate readings.

-

Recommended Models from the Same Series or Related Models

| Model | Description | Key Features |

|---|---|---|

| Bently Nevada 3300/50 | Tachometer Monitor | Measures rotational speed with high precision. |

| Bently Nevada 3300/75 | Dual Velocity and Acceleration Monitor | Monitors both velocity and acceleration parameters. |

| Bently Nevada 3300/90 | Multi-Parameter Monitoring System | Supports various sensors for comprehensive data analysis. |

| Bently Nevada 3500/50 | Advanced Vibration Monitor | Upgraded model with enhanced monitoring capabilities. |

| Bently Nevada 3500/42 | Vibration Monitor with Advanced Signal Processing | Provides detailed vibration analysis and diagnostics. |

| Bently Nevada 3300/65 | Dual Displacement and Velocity Monitor | Measures both displacement and velocity simultaneously. |

| Bently Nevada 3300/10 | Basic Vibration Monitor | Suitable for monitoring smaller industrial machines. |

| Bently Nevada 3300/20 | Single-Channel Vibration Monitor | Standard single-input vibration measurement device. |

Recommended Popular Models from Bently Nevada

| Model | Description | Key Features |

|---|---|---|

| Bently Nevada 3500/22 | Advanced Machinery Protection System | High-speed data acquisition with multiple input channels. |

| Bently Nevada 3500/60 | Advanced Dual-Input Vibration Monitor | Ideal for turbines, compressors, and pumps. |

| Bently Nevada 3500/61 | Rotating Machinery Health Monitor | Provides real-time diagnostics for industrial applications. |

| Bently Nevada 3500/40 | Four-Channel Vibration Monitor | Monitors multiple machines with high accuracy. |

| Bently Nevada 3500/72 | Advanced Monitoring System for Large Equipment | Designed for high-speed rotating machinery applications. |

| Bently Nevada 3300/35 | Signal Processing Unit | Offers comprehensive signal analysis capabilities. |

| Bently Nevada 3300/05 | Displacement and Velocity Transducer | Measures both displacement and velocity parameters. |

| Bently Nevada 3300/80 | Machinery Diagnostic System | Integrated diagnostics for predictive maintenance. |

Excellent PLC

Excellent PLC