| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

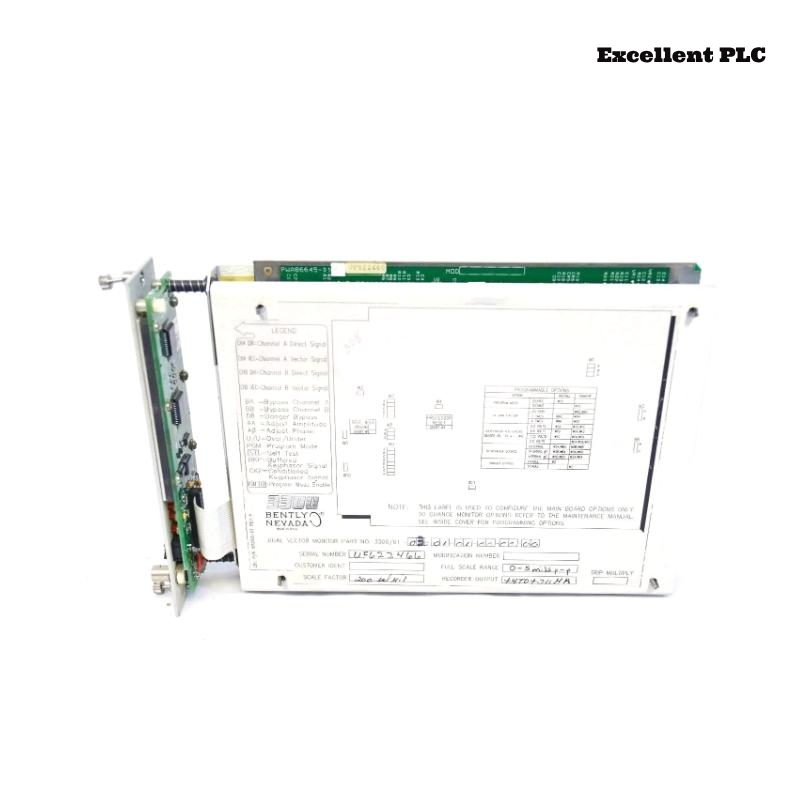

The Bently Nevada 3300/61 Dual Vector Monitor is part of the 3300 Series from Bently Nevada, a renowned leader in condition monitoring and machinery protection systems. The 3300/61 is specifically designed to provide real-time monitoring and diagnostic capabilities for critical machinery. It utilizes advanced vibration monitoring technology and allows for the analysis of complex machinery behavior, making it ideal for industries such as oil and gas, power generation, mining, and manufacturing. The device can track and measure the vibration in rotating equipment, helping prevent failures and improve reliability.

Product Specifications:

Below are the detailed specifications of the Bently Nevada 3300/61 Dual Vector Monitor:

| Parameter | Specification |

|---|---|

| Model Number | 3300/61 Dual Vector Monitor |

| Input Channels | 2 (Dual Input) |

| Input Signal Type | Vibration, Velocity, Displacement |

| Signal Conditioning | Dual-channel, independent signal processing |

| Display Type | LED Display |

| Measurement Range | 0.1 mil to 1.0 inch (0.0025mm to 25.4mm) |

| Data Sampling Rate | 512 Samples per second |

| Power Supply | 24V DC or 115V/230V AC |

| Operating Temperature Range | -40°C to +85°C (-40°F to 185°F) |

| Dimensions | 254 x 165 x 63.5 mm |

| Weight | 1 kg |

| Mounting Type | Panel Mount or Rack Mount |

| Output Type | 4-20 mA, Alarm relay outputs |

| Certification | CE, UL, RoHS Compliant |

| Communications | Modbus RTU, Profibus, or Ethernet optional |

Product Applications:

The Bently Nevada 3300/61 Dual Vector Monitor is primarily used in industries where machine reliability and condition monitoring are critical. Some key applications include:

-

Oil and Gas: For monitoring critical pumps, compressors, and turbines.

-

Power Generation: Ensures the safe operation of generators, turbines, and auxiliary equipment.

-

Mining and Minerals Processing: Monitors crushers, conveyors, and mills to prevent downtime.

-

Manufacturing: Used in CNC machines, HVAC systems, and high-speed machinery to ensure continuous operations.

-

Water Treatment Plants: Monitoring of pumps and motors to avoid mechanical failure.

-

Pulp and Paper Mills: Vibration monitoring of large rollers and mills.

Product Advantages:

-

Advanced Monitoring Capabilities: Offers dual-channel monitoring with precise data analysis to detect early signs of machinery failure.

-

Flexible Input Options: Compatible with vibration, velocity, and displacement measurements to meet diverse machinery needs.

-

Real-Time Diagnostics: Provides immediate feedback on machinery health, which helps in making timely decisions for maintenance.

-

Improved Reliability: Helps reduce unplanned downtime and extends equipment lifespan by identifying issues early.

-

Compact Design: Easy to install and mount in control panels or racks, saving valuable space.

-

Versatility: Offers multiple communication options such as Modbus and Ethernet for integration into existing systems.

-

User-Friendly Interface: Simple LED display for quick diagnostics and monitoring, with customizable alarm settings.

-

Environmentally Robust: Withstands harsh environments, featuring a wide temperature operating range and high durability.

Latest News Headlines:

-

“Bently Nevada Enhances Industrial Machinery Protection with 3300/61 Dual Vector Monitor”

-

“New Dual Vector Monitor from Bently Nevada Revolutionizes Vibration Analysis in Critical Equipment”

-

“Bently Nevada’s 3300/61 Monitor Empowers Predictive Maintenance in Oil and Gas Industries”

-

“Bently Nevada 3300/61: The Next Generation of Real-Time Vibration Monitoring Solutions”

-

“How the 3300/61 Monitor Can Save Your Equipment from Costly Failures”

-

“The Role of Dual Vector Monitoring in Preventing Unplanned Downtime in Manufacturing”

-

“Unveiling the Latest Dual Vector Monitor: A Game-Changer for Power Generation Applications”

-

“How Bently Nevada’s Latest Innovation is Enhancing Asset Integrity Management”

FAQ (Frequently Asked Questions):

-

What is the Bently Nevada 3300/61 Dual Vector Monitor?

-

It is a vibration monitoring device used for real-time diagnostics of critical machinery, capable of tracking vibration, velocity, and displacement.

-

-

How many channels does the 3300/61 monitor have?

-

The device has two independent channels for monitoring two different points of a machine simultaneously.

-

-

What type of signals can the 3300/61 monitor?

-

It can monitor vibration, velocity, and displacement signals from the machine.

-

-

What industries is the Bently Nevada 3300/61 suitable for?

-

It is ideal for industries like oil and gas, power generation, mining, and manufacturing.

-

-

What is the range of the measurement capability?

-

The device can measure from 0.1 mil to 1.0 inch (0.0025mm to 25.4mm).

-

-

Does the monitor provide real-time diagnostics?

-

Yes, it offers real-time data for early detection of potential equipment failures.

-

-

How is the Bently Nevada 3300/61 powered?

-

It can be powered by 24V DC or 115V/230V AC depending on your setup.

-

-

What kind of output signals does it provide?

-

The monitor offers 4-20 mA output and relay alarms.

-

-

Can the 3300/61 be used in harsh environments?

-

Yes, it is designed to operate in extreme temperature ranges from -40°C to +85°C.

-

-

How is the Bently Nevada 3300/61 installed?

-

It can be panel-mounted or rack-mounted for flexible installation in control rooms or machinery.

-

Related Models:

Here are 8 other related models from the Bently Nevada 3300 Series:

| Model | Specification |

|---|---|

| 3300/20 | Single Channel Vibration Monitor, 4-20mA Output |

| 3300/03 | Proximity Probe Monitor, Dual Output |

| 3300/05 | Vibration Transmitter for Large Motors |

| 3300/01 | Single Channel Proximity Monitoring |

| 3300/02 | Digital Vibration Monitoring System |

| 3300/03 | Vibration Monitoring with RMS and Peak hold |

| 3300/30 | Remote Monitoring with Ethernet Communication |

| 3300/51 | Advanced Machinery Protection with Dual Inputs |

Popular Models from Bently Nevada:

Below are 8 popular models from Bently Nevada:

| Model | Specification |

|---|---|

| 3300/20 | Single Channel Vibration Monitor |

| 3300/10 | Vibration Monitoring System for Motors |

| 3500/42 | Dynamic Pressure Monitor |

| 3500/44M | Machinery Protection Monitor |

| 3500/22M | Dual Channel Vibration Monitoring System |

| 3500/93 | Data Acquisition Module for Vibration Analysis |

| 3500/33 | Accelerometer for Vibration Monitoring |

| 3500/61 | Advanced Machinery Protection and Diagnostics |

Excellent PLC

Excellent PLC