| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

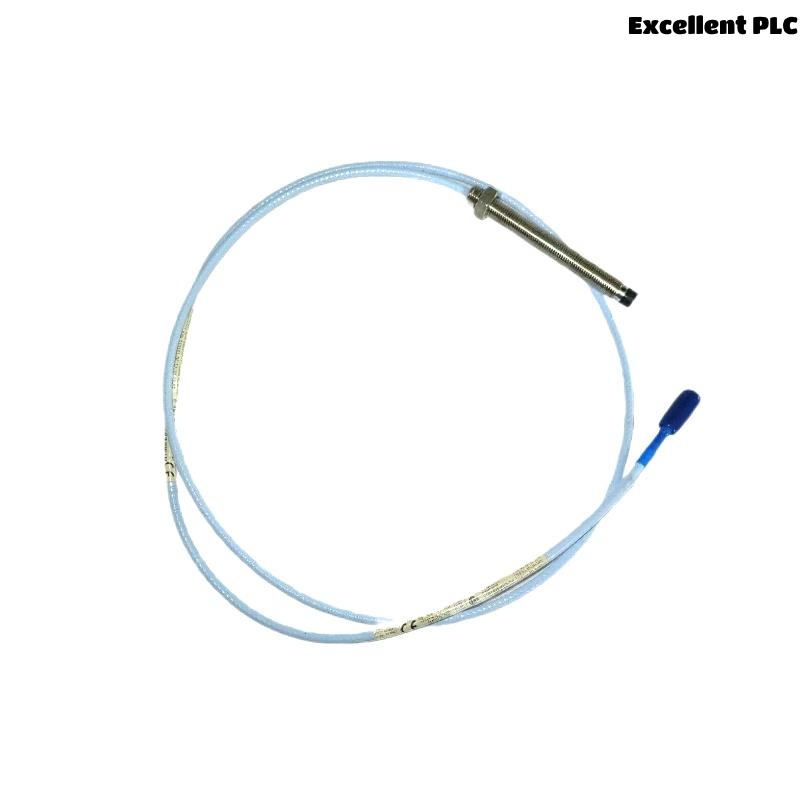

Bently Nevada 330101-00-08-05-02-00 is a proximity probe from the 3300 XL 8 mm series, designed to provide highly accurate, non-contact displacement and vibration measurements for critical machinery monitoring. This particular model is widely implemented in heavy industrial applications such as turbines, compressors, pumps, and motors.

The probe is a key component in condition monitoring systems and is compatible with 3300 XL Proximitor® sensors and extension cables. It is built for durability in harsh environments, ensuring continued precision over long operational lifetimes. The 3300 XL series is recognized globally for its reliable performance in high-speed rotating equipment.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-08-05-02-00 |

| Series | 3300 XL 8 mm |

| Probe Tip Diameter | 8 mm |

| Thread Type | 3/8-24 UNF |

| Unthreaded Length | 0.8 inch (20.3 mm) |

| Total Length | 0.5 meter (19.7 inches) |

| Connector Type | ClickLoc™ miniature coaxial connector |

| Operating Temperature | -51°C to +177°C (-60°F to +351°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Frequency Range | DC to 10 kHz |

| Linear Range | 2 mm (80 mils) |

| Output Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Weight | 0.162 kg |

| Ingress Protection | IP67 |

| Material – Probe Tip | PPS (Polyphenylene sulfide) |

| Material – Case | AISI 303/304 Stainless Steel |

| Compliance | API 670 4th Edition |

Applications

The 330101-00-08-05-02-00 proximity probe is engineered for non-contact vibration and position monitoring in rotating machinery. Its primary applications include:

-

Steam and Gas Turbines: Shaft vibration and axial position monitoring

-

Centrifugal Compressors: Detecting rotor instability and imbalance

-

Industrial Pumps: Monitoring bearing health and shaft misalignment

-

Motors and Generators: Ensuring vibration levels remain within safe limits

-

Gearboxes and Fans: Continuous machinery health monitoring

-

Nuclear, Oil & Gas, Petrochemical Plants: Compliance with API 670 for critical equipment protection

Key Advantages

-

Durable Construction: Built with corrosion-resistant stainless steel and rugged PPS materials, suitable for extreme environments.

-

API 670 Compliance: Fully meets API 670 specifications for vibration and position monitoring systems.

-

Temperature Tolerance: Wide operational range allows for use in both cryogenic and high-temperature applications.

-

Plug-and-Play Compatibility: Seamless integration with 3300 XL systems including Proximitor® sensors and extension cables.

-

ClickLoc™ Secure Connection: Provides a tight, reliable connector interface, resistant to vibration loosening.

-

Long Service Life: Proven durability in field deployments with minimal signal drift over time.

Frequently Asked Questions (FAQs)

-

What is the purpose of the 330101-00-08-05-02-00 probe?

The probe measures the distance between the probe tip and a conductive target (usually a rotating shaft), enabling vibration and position monitoring in machinery. -

What does the 8 mm tip size indicate?

The 8 mm tip size refers to the diameter of the probe tip, which determines the sensing range and field characteristics. -

Is the probe resistant to moisture or dust?

Yes, it is rated IP67, which means it is dust-tight and can withstand temporary immersion in water. -

Can this probe be installed in hazardous environments?

While this model is robust, certification for hazardous environments depends on the complete monitoring system. Consult documentation for full ATEX/IECEx compatibility. -

What kind of machinery is this probe suitable for?

Ideal for high-speed rotating equipment such as turbines, compressors, and large motors, especially in mission-critical installations. -

Can I use this probe with a 3300 XL Proximitor Sensor from another probe model?

Yes, it is fully interchangeable within the 3300 XL 8 mm system and does not require individual component matching. -

What is the maximum cable length supported?

The 3300 XL system supports standard cable lengths up to 9 meters, with calibration maintained across the specified length. -

How is the probe installed?

It screws into the machine casing using a 3/8-24 UNF threaded mount and connects via the ClickLoc™ connector. -

Does this probe support dual-axis or multi-channel monitoring?

No, this specific model is single-axis; however, it can be used in dual-probe configurations for XY monitoring. -

What kind of signal does this probe produce?

It outputs a voltage proportional to the distance between the probe tip and the target surface, usually interpreted by a Proximitor® sensor.

Related Models from the Same Series

| Model Number | Description |

|---|---|

| 330101-00-12-10-02-00 | 8 mm Probe, 1.2″ length, 1.0 m cable |

| 330103-00-10-10-02-00 | Armored cable version, 1.0 m, 1.0″ length |

| 330103-00-08-05-02-00 | Armored cable version, 0.5 m cable |

| 330104-00-10-10-02-00 | Reverse mount version, 1.0 m cable |

| 330130-040-00-00 | Extension Cable, 4.0 m |

| 330180-91-00 | 3300 XL Proximitor Sensor, 9 m system |

Other Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/22M-01-01-00 | Keyphasor Module for 3500 System |

| 3500/42M-01-00 | Proximitor Monitor, 4-channel |

| 3500/33-01-01 | Temperature Monitor |

| 330105-02-12-10-02-05 | Proximity Probe, 8 mm tip, 1.2″, 2.0 m cable |

| 330106-05-30-10-02-05 | Probe, 3.0” length, 5 m cable |

| 3500/15-05-02-00 | Power Supply Module, High Voltage AC |

Excellent PLC

Excellent PLC