| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

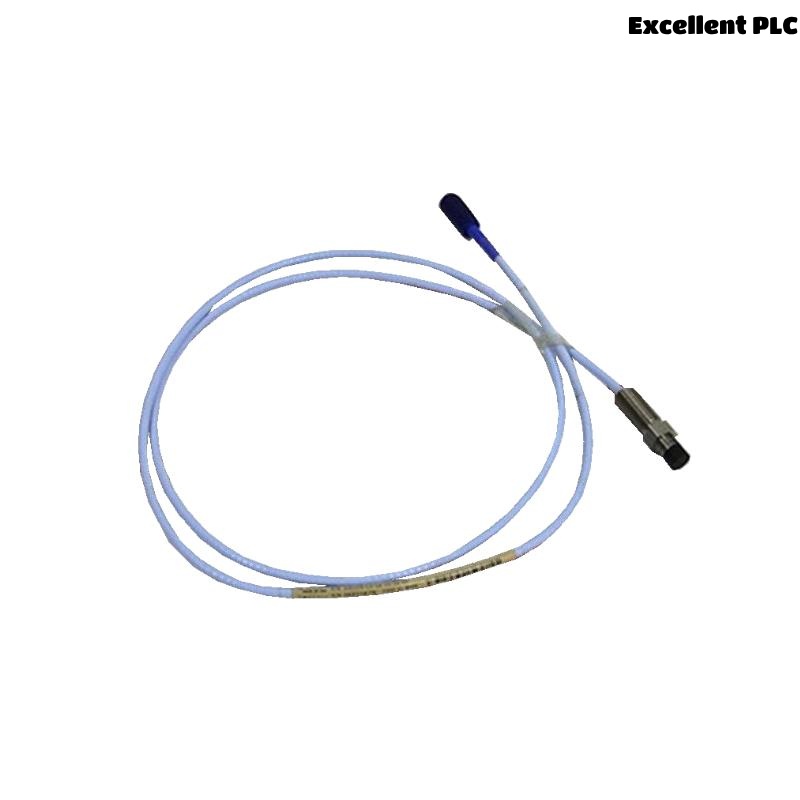

The Bently Nevada 330101-00-08-20-12-05 3300 XL 8 mm Proximity Probe is an industry-leading vibration sensor designed for precise shaft position and vibration monitoring in rotating machinery. Engineered for reliability and durability, this proximity probe forms a critical component of the Bently Nevada 3300 XL Series monitoring system. With an 8 mm tip length, it provides exceptional sensitivity and resolution to detect minute shaft displacements, enabling early fault detection and helping prevent catastrophic equipment failures.

Manufactured by Bently Nevada, a trusted name in condition monitoring, this probe excels in harsh industrial environments such as power generation, oil and gas, and heavy manufacturing. Its robust construction ensures long service life and consistent performance under demanding conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-08-20-12-05 |

| Series | 3300 XL |

| Probe Tip Length | 8 mm |

| Probe Type | Proximity probe (eddy-current) |

| Measurement Range | ±2 mm (typical) |

| Output Signal | AC voltage output |

| Operating Temperature Range | -40°C to +120°C |

| Cable Length | 2 meters |

| Cable Type | Shielded, 2-conductor, twisted pair |

| Probe Housing Material | Stainless steel |

| Connector Type | MIL-C-5015 (standard) |

| Weight | 0.646 kg |

| Environmental Protection | IP67 rated |

Applications

The 3300 XL 8 mm Proximity Probe is primarily used for:

-

Rotating machinery monitoring: Turbines, compressors, pumps, and generators.

-

Vibration and shaft displacement measurement: Essential for identifying imbalance, misalignment, bearing wear, and shaft rub.

-

Condition-based maintenance programs: Enables predictive maintenance by providing early warning signs of mechanical degradation.

-

High-speed machinery: Suitable for machinery operating at speeds up to tens of thousands of RPM.

-

Harsh environments: Designed to operate reliably in extreme temperatures, moisture, and dusty or oily environments.

-

Power plants: Steam, gas, and hydro turbine monitoring.

-

Oil and gas industry: Offshore and onshore rotating equipment condition monitoring.

-

Manufacturing: Critical machinery health monitoring to reduce unplanned downtime.

Advantages

-

High precision sensing: Provides accurate, stable shaft position readings with minimal drift over time.

-

Robust design: Stainless steel housing and IP67 rating ensure durability in challenging industrial settings.

-

Long service life: Engineered for extended operational periods with minimal maintenance.

-

Compatibility: Fully compatible with Bently Nevada 3300 XL monitoring systems and retrofit friendly.

-

Wide temperature range: Can perform reliably in extreme temperature conditions from -40°C up to +120°C.

-

Enhanced safety: Early fault detection reduces the risk of catastrophic equipment failure, protecting personnel and assets.

-

Low noise output: Ensures high signal integrity for precise diagnostics.

-

Simple installation and maintenance: Standardized connectors and rugged cables ease integration.

-

Global support network: Backed by Bently Nevada’s worldwide service and technical assistance.

-

Proven track record: Trusted by industries worldwide for over decades of reliable operation.

Frequently Asked Questions (FAQ)

-

What is the typical sensing distance for this probe?

The typical gap between the probe tip and the target shaft surface is about 8 mm, with a measurement range of ±2 mm for vibration. -

Can this probe be used in explosive environments?

Yes, when paired with the appropriate intrinsic safety barriers and certified monitoring systems, it can be used in hazardous locations. -

What type of output signal does the probe produce?

It produces an AC voltage output proportional to the distance between the probe tip and the rotating shaft. -

How long is the standard cable length?

The standard cable length is 2 meters but can be customized upon request. -

What maintenance is required for the probe?

The probe requires minimal maintenance; periodic visual inspections and cleaning of the tip are recommended. -

Is the probe compatible with other manufacturers’ monitoring systems?

It is primarily designed for Bently Nevada 3300 XL systems but may work with other systems supporting eddy-current proximity probes. -

What is the operating temperature range of the probe?

The probe operates reliably between -40°C and +120°C. -

How resistant is the probe to vibration and shock?

The probe is rated to withstand vibration up to 100 g and mechanical shocks common in industrial environments. -

What materials is the probe made from?

The housing is stainless steel for corrosion resistance, with a hardened probe tip. -

Can the probe detect axial movement?

This probe is designed for radial displacement detection. Axial measurements require different sensor arrangements.

Recommended Related Models (Same Series / Related)

| Model Number | Probe Tip Length | Cable Length | Connector Type | Notes |

|---|---|---|---|---|

| 330101-00-05-20-12-05 | 5 mm | 2 m | MIL-C-5015 | Shorter tip for close clearance |

| 330101-00-12-20-12-05 | 12 mm | 2 m | MIL-C-5015 | Longer tip for deep sensing |

| 330101-00-08-30-12-05 | 8 mm | 3 m | MIL-C-5015 | Extended cable for remote mounting |

| 330101-00-08-20-10-05 | 8 mm | 2 m | M12 Connector | Alternate connector style |

| 330101-00-08-20-12-10 | 8 mm | 2 m | MIL-C-5015 | Enhanced temperature rating |

| 330102-00-08-20-12-05 | 8 mm | 2 m | MIL-C-5015 | Improved EMI shielding |

Popular Models from Bently Nevada (Different Series or Brands)

| Model Number | Description | Probe Tip Length | Connector Type | Application Focus |

|---|---|---|---|---|

| 330112-00-08-20-12-05 | 3300 XL Proximity Probe with shielded cable | 8 mm | MIL-C-5015 | Heavy industry rotating machinery |

| 330101-00-05-20-12-01 | 3300 XL 5 mm Proximity Probe | 5 mm | MIL-C-5015 | Compact machinery |

| 7200-03-04-00-01 | 7200 Series Vibration Transmitter | N/A | N/A | Overall vibration monitoring |

| 3500/50-14-01-00 | 3500 Series Vibration Monitor | N/A | N/A | Complete monitoring system |

| 330102-00-10-20-12-05 | 3300 XL 10 mm Proximity Probe | 10 mm | MIL-C-5015 | Large shaft monitoring |

| 330104-00-12-20-12-05 | 3300 XL 12 mm Proximity Probe | 12 mm | MIL-C-5015 | Extended sensing range |

Excellent PLC

Excellent PLC