| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

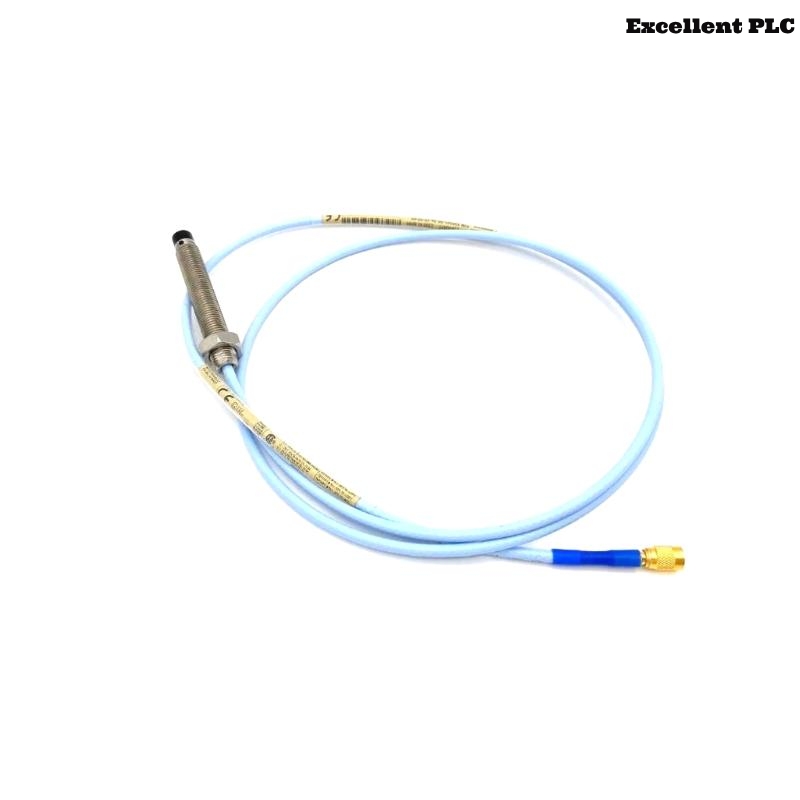

The Bently Nevada 330101-00-10-10-02-00 is a part of the renowned 3300 XL 8mm Proximity Transducer System, widely trusted for critical machinery protection and condition monitoring in industrial environments. Engineered by Bently Nevada, a trusted name under Baker Hughes, this proximity probe is designed to provide accurate, stable, and reliable non-contact measurement of shaft vibration, position, and speed.

This specific part number refers to an 8mm tip probe with a total system length of 10 feet (including extension cable and proximity transducer). It is commonly paired with the 3300 XL Proximitor Sensor and extension cables to form a complete transducer system. The probe is suitable for measuring dynamic and static signals in harsh environments, offering industry-leading performance across a wide range of temperatures and installation conditions.

The 330101-00-10-10-02-00 is fully API 670 compliant and supports long-term operational reliability with minimal signal drift. It is used globally in power generation, oil & gas, petrochemical, and rotating machinery systems.

Technical Specifications

| Parameter | Details |

| Model | 330101-00-10-10-02-00 |

| Series | 3300 XL 8mm |

| Sensing Technology | Eddy Current (Non-contact) |

| Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector with ClickLoc™ locking mechanism |

| Target Material | AISI 4140 Steel (calibrated) |

| Mounting Thread | 1/4-28 UNF-2A |

| Body Style | Unthreaded, Armored Cable |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Output Voltage Range | 0 to -24 Vdc (typical scale factor: -200 mV/mil or -7.87 mV/μm) |

| Linear Range | 2 mm (80 mils) |

| Non-linearity | Within ±0.25% of full scale range |

| Weight | 0.323 kg |

| Enclosure Rating | IP65 (with proper installation) |

| Compliance | API 670, CE, RoHS |

Applications

The Bently Nevada 330101-00-10-10-02-00 is widely used across a range of industrial sectors due to its precision and robustness. Applications include:

-

Turbomachinery Vibration Monitoring

Detects shaft vibration in steam turbines, gas turbines, and compressors. -

Shaft Position Monitoring

Used in axial thrust position detection in thrust bearing applications. -

Rotating Equipment Condition Monitoring

Ensures optimal operation of pumps, motors, blowers, and gearboxes. -

Critical Process Equipment

Integral in systems requiring continuous reliability such as refineries and offshore platforms. -

Speed Sensing

When used with Keyphasor™ modules, allows for precise RPM tracking. -

Industrial Plant Asset Management

Forms part of online monitoring systems within predictive maintenance programs.

Product Advantages

-

Superior Reliability

Designed for extreme conditions, offering stable performance over wide temperature ranges. -

Excellent Linearity and Accuracy

Industry-leading non-contact measurement within tight linearity tolerance. -

API 670 Compliance

Meets the stringent requirements of API 670 for machine protection systems. -

Versatile and Modular

Interchangeable probe, extension cable, and sensor design simplify maintenance and upgrades. -

Corrosion and Vibration Resistant

Rugged stainless steel construction with armored cable protection. -

Ease of Installation

Compact design with a ClickLoc connector ensures secure and reliable field installation.

Frequently Asked Questions (FAQ)

1. What does the part number 330101-00-10-10-02-00 mean?

It designates a Bently Nevada 8mm proximity probe with 10 feet system length, unthreaded body, armored cable, and standard connector.

2. Is this probe compatible with older 7200 or 3300 series proximitor systems?

No, the 3300 XL probes are not backward compatible with older systems due to changes in system calibration and electrical characteristics.

3. What is the minimum bend radius for the cable?

The minimum bend radius for the armored cable is 25 mm (1 inch), but avoiding repeated bends is recommended.

4. Can this probe be used in explosive or hazardous areas?

Only if installed in an approved enclosure or system certified for hazardous area usage.

5. What calibration material is used?

The probe is calibrated using AISI 4140 steel by default, unless otherwise specified.

6. How do I mount the probe correctly?

Follow the installation manual ensuring the probe is perpendicular to the shaft with correct gap and lock nut torque.

7. What is the output signal of this proximity probe?

The output is a negative voltage proportional to the distance from the target, typically -200 mV/mil.

8. Can this probe measure axial and radial vibration?

Yes, depending on installation orientation and sensor pairing.

9. How often should the probe be replaced?

Typically only if damaged; however, periodic recalibration or system validation is recommended per maintenance schedules.

10. What is the main difference between 3300 XL 5mm and 8mm probes?

The 8mm version offers a longer linear range and is better suited for larger shaft diameters or increased vibration amplitudes.

Recommended Related Models (Same Series / Similar Purpose)

| Model Number | Description | Tip Size | Cable Length | Comments |

|---|---|---|---|---|

| 330101-00-05-10-02-00 | 3300 XL 8mm Probe, 5 ft system length | 8 mm | 5 ft | Shorter length version |

| 330101-00-15-10-02-00 | 3300 XL 8mm Probe, 15 ft system length | 8 mm | 15 ft | Extended cable length |

| 330103-00-10-10-02-00 | 3300 XL 5mm Probe, 10 ft system length | 5 mm | 10 ft | Narrower tip for tight spaces |

| 330104-00-10-10-02-00 | High Temperature 8mm Probe, 10 ft system | 8 mm | 10 ft | Withstands higher temperature range |

| 330105-02-12-10-02-00 | Reverse Mount 8mm Probe | 8 mm | 12 ft | For limited mounting space |

| 3300 XL NSv Probe | Narrow Side View Probe for tight radial clearances | 5 mm | Various | For confined installations |

Recommended Popular Bently Nevada Models

| Model Number | Function | Application | Series | Mounting Type |

|---|---|---|---|---|

| 330104-00-12-10-02-00 | High-Temp Proximity Probe | Steam Turbines | 3300 XL | Threaded |

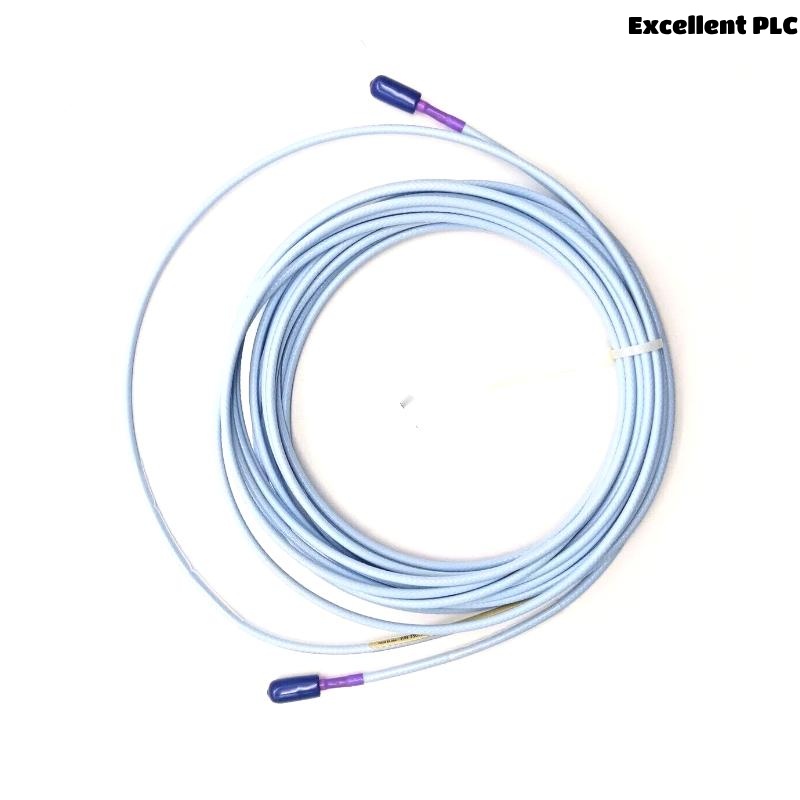

| 330130-040-00 | Extension Cable | General Purpose | 3300 XL | N/A |

| 330180-91-05 | Proximitor Sensor | Probe Signal Conditioning | 3300 XL | DIN Rail Mounted |

| 330106-05-30-10-02-00 | Probe with Reverse Mount Option | Axial Position Measurement | 3300 XL | Reverse Mount |

| 330500-02-00 | Velocity Sensor | Seismic Vibration Measurement | 330500 Series | Stud Mount |

| 3500/42M | Vibration Monitor Module | Machine Protection Systems | 3500 Series | Rack-Mounted |

Excellent PLC

Excellent PLC