| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

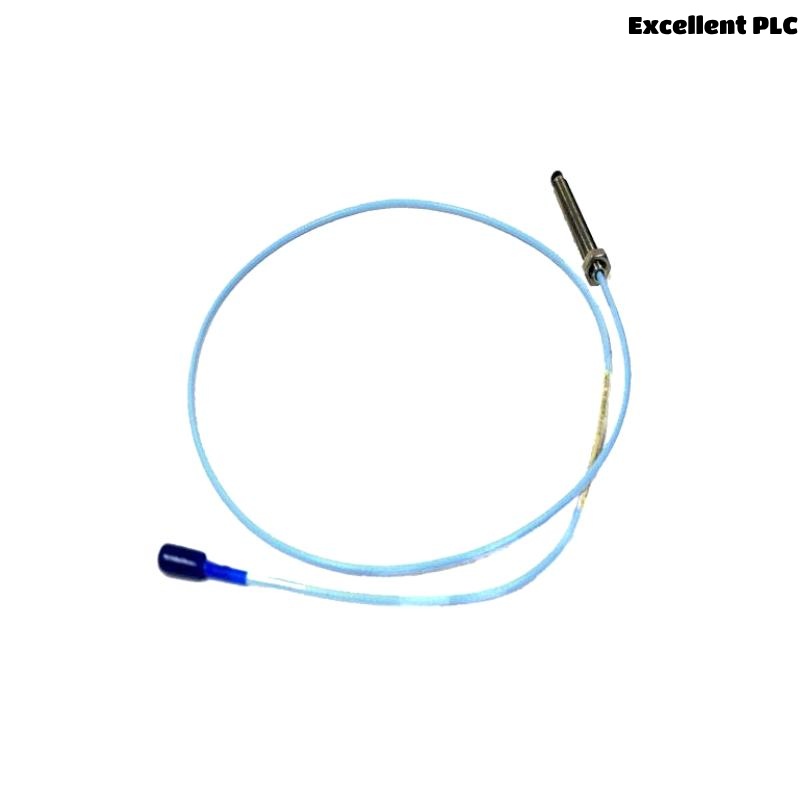

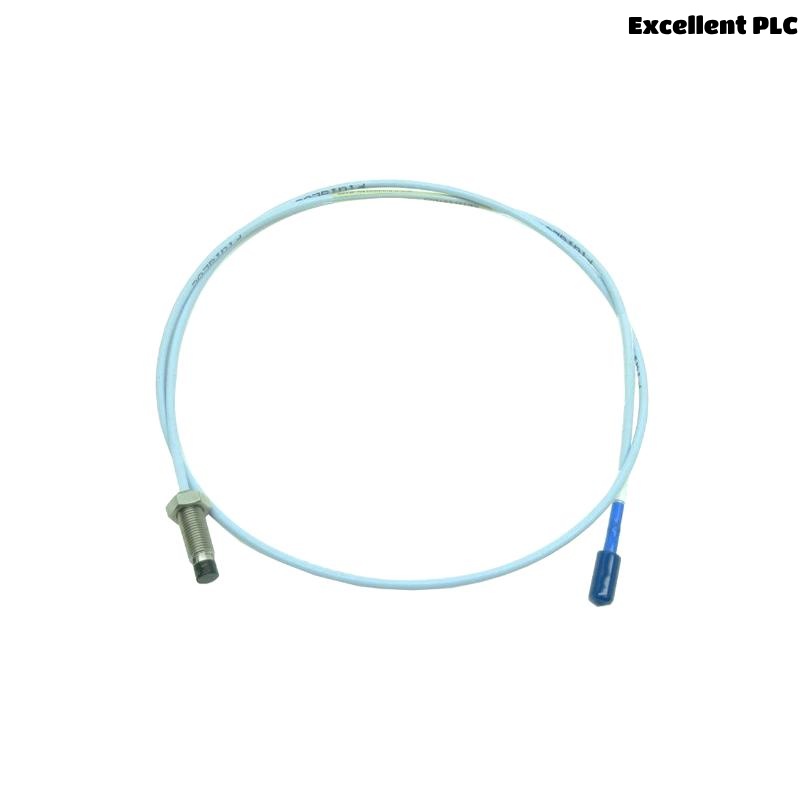

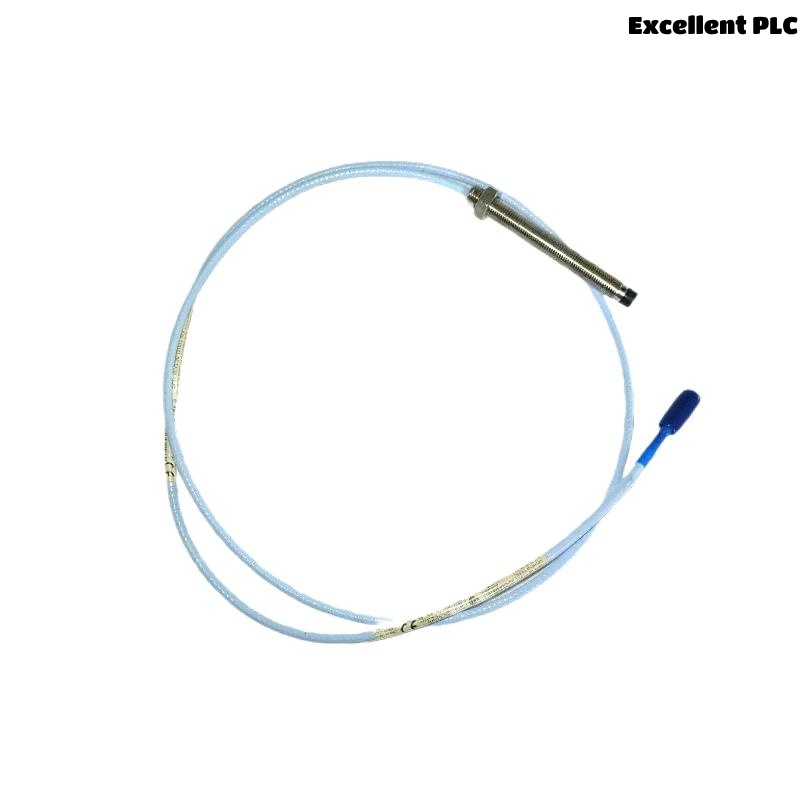

The Bently Nevada 330101-00-11-10-02-CN 3300 XL 8 mm Proximity Probe is a highly precise sensor designed for condition monitoring of rotating machinery. Part of the well-regarded 3300 XL series, this probe employs eddy-current technology to accurately measure the radial displacement of shafts, helping operators monitor vibration, shaft position, and movement with excellent precision.

The “8 mm” in its name indicates the sensing tip length, which is optimized for applications requiring a moderate measurement gap. The “-CN” suffix often points to specific regional or cable configurations, which are designed to meet particular installation or environmental needs.

Manufactured by Bently Nevada, a pioneer in machinery protection systems, this probe is built for industrial robustness, offering reliable operation in demanding environments such as power plants, oil and gas facilities, and heavy manufacturing industries. It ensures early fault detection and supports predictive maintenance, minimizing downtime and reducing maintenance costs.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-11-10-02-CN |

| Series | 3300 XL |

| Probe Tip Length | 8 mm |

| Probe Type | Eddy-current proximity sensor |

| Measurement Range | ±2 mm typical |

| Output Signal | AC voltage output |

| Operating Temperature Range | -40°C to +120°C |

| Cable Length | 1 meter |

| Cable Type | Shielded, twisted-pair |

| Housing Material | Stainless steel |

| Connector Type | MIL-C-5015 |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Weight | 0.323 kg |

| Environmental Protection | IP67 |

| Vibration Resistance | Up to 100 g |

Applications

This proximity probe serves a critical role in:

-

Rotating machinery monitoring: turbines, compressors, pumps, and motors where shaft position and vibration must be tracked continuously.

-

Vibration analysis and shaft displacement measurement: helps detect imbalance, misalignment, bearing degradation, and shaft rub issues.

-

Predictive maintenance programs: allowing early warning of potential machinery failure to avoid unplanned downtime.

-

High-speed machinery: capable of handling high RPM applications requiring precise displacement readings.

-

Harsh and hazardous environments: designed to operate under extreme temperature, moisture, dust, and vibration conditions.

-

Power generation industry: including steam, gas, and hydroelectric turbines.

-

Oil and gas sector: monitoring rotating equipment in refineries and offshore rigs.

-

Industrial manufacturing: safeguarding pumps, fans, and other rotating assets critical to continuous operations.

Advantages

-

Precision and reliability: Delivers consistent and accurate shaft position data, aiding detailed vibration analysis.

-

Robust construction: Stainless steel housing and IP67 rating protect against corrosion, dust, and water ingress.

-

Extended cable length: The cable variant facilitates installation in hard-to-reach or large machinery setups.

-

Wide temperature range: Reliable operation from -40°C to +120°C for diverse industrial climates.

-

Compatibility: Fully compatible with Bently Nevada 3300 XL monitoring systems and accessories.

-

Noise reduction: Shielded cable and optimized electronics reduce signal interference, enhancing measurement fidelity.

-

Shock and vibration resistance: Can withstand severe mechanical shocks up to 100 g without performance loss.

-

Easy installation: MIL-C-5015 connectors ensure secure, rugged, and quick connections.

-

Supports predictive maintenance: Enables early detection of faults, improving plant safety and reducing repair costs.

-

Global service and support: Backed by Bently Nevada’s worldwide technical and customer service network.

Frequently Asked Questions (FAQ)

-

What does the “8 mm” signify in the product name?

It refers to the sensing tip length, meaning the probe measures shaft displacement at an 8 mm distance from the target. -

What is the total length for this model?

The “-10” indicates an 1 meter standard total length. -

Is this probe compatible with other Bently Nevada 3300 XL system components?

Yes, it is designed to integrate seamlessly with all 3300 XL monitoring modules and systems. -

What operating temperature range does the probe support?

It operates reliably from -40°C to +120°C. -

How does the probe connect to the monitoring system?

Via a rugged MIL-C-5015 connector, standard in industrial environments. -

Can this probe be used in hazardous environments?

Yes, with appropriate safety measures and certified systems, it can be deployed in hazardous locations. -

What maintenance is required?

Minimal; routine inspections and cleaning of the sensing tip area are recommended. -

What is the probe’s resistance to vibration and shock?

It can tolerate mechanical shocks and vibration up to 100 g. -

Does this probe measure axial shaft displacement?

No, it only measures radial displacement. -

What material is the probe housing made of?

The probe housing is stainless steel, offering corrosion resistance and durability.

Recommended Related Models (Same Series / Related)

| Model Number | Probe Tip Length | Cable Length | Connector Type | Notes |

|---|---|---|---|---|

| 330101-00-05-10-02-CN | 5 mm | 10 m | MIL-C-5015 | Shorter sensing tip |

| 330101-00-12-11-02-CN | 12 mm | 11 m | MIL-C-5015 | Longer tip with similar cable |

| 330101-00-08-15-02-CN | 8 mm | 15 m | MIL-C-5015 | Extended cable length |

| 330101-00-08-05-02-CN | 8 mm | 5 m | MIL-C-5015 | Short cable for tight spaces |

| 330102-00-08-11-02-CN | 8 mm | 11 m | MIL-C-5015 | Enhanced EMI shielding |

| 330101-00-08-20-02-CN | 8 mm | 20 m | MIL-C-5015 | Extra-long cable for large installations |

Popular Bently Nevada Models (Different Series / Brand)

| Model Number | Description | Probe Tip Length | Connector Type | Application Focus |

|---|---|---|---|---|

| 330112-00-08-20-12-05 | 3300 XL Proximity Probe | 8 mm | MIL-C-5015 | Heavy industrial machinery |

| 330101-00-05-20-12-01 | 3300 XL 5 mm Proximity Probe | 5 mm | MIL-C-5015 | Compact machine monitoring |

| 7200-03-04-00-01 | 7200 Series Vibration Transmitter | N/A | N/A | Overall vibration monitoring |

| 3500/50-14-01-00 | 3500 Series Vibration Monitor | N/A | N/A | Comprehensive condition monitoring |

| 330102-00-10-20-12-05 | 3300 XL 10 mm Proximity Probe | 10 mm | MIL-C-5015 | Larger shaft measurement |

| 330104-00-12-20-12-05 | 3300 XL 12 mm Proximity Probe | 12 mm | MIL-C-5015 | Extended sensing for bigger machinery |

Excellent PLC

Excellent PLC