| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

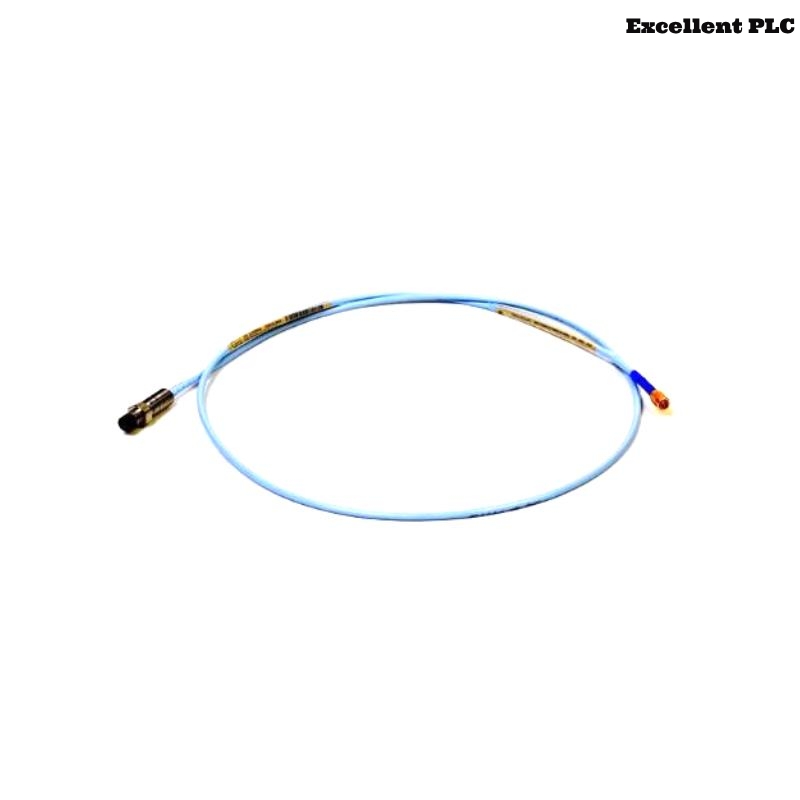

The Bently Nevada 330101-00-12-05-02-00 is a premium non-contact proximity probe engineered to monitor the relative vibration and position of rotating shafts. Designed as part of the 3300 XL 8mm Proximity Transducer System, this probe ensures exceptional performance in industrial and critical machinery applications such as turbines, compressors, pumps, and motors.

This particular part number represents an 8 mm probe tip, a 12-foot probe cable, a 5 mm thread size (UNF 1/4-28), a straight connector configuration, and armor-less construction. It is optimized for pairing with the 3300 XL extension cable and Proximitor Sensor, and the entire system complies with API 670 standards, making it suitable for demanding condition monitoring and machinery protection systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-12-05-02-00 |

| Series | 3300 XL 8mm |

| Sensor Type | Eddy Current Proximity Probe (Non-contact) |

| Tip Diameter | 8 mm (0.31 in) |

| Cable Length | 12 ft (3.66 m) |

| Mounting Thread Size | 1/4-28 UNF-2A (05) |

| Connector Type | Miniature coaxial ClickLoc™ |

| Body Style | Unarmored (non-armored cable construction) |

| Target Material | Calibrated to AISI 4140 steel |

| Linear Range | 2 mm (80 mils) |

| Output Sensitivity | -200 mV/mil (≈ -7.87 mV/μm) |

| Non-linearity | Within ±0.25% of full-scale |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Weight | 0.246 kg |

| Total Length | 0.5 m |

| Minimum Cable Bend Radius | 25 mm (1 in) |

| Compliance Standards | API 670, CE, RoHS compliant |

| Environmental Protection | IP65 (when installed with proper sealing) |

Applications

The 330101-00-12-05-02-00 proximity probe is widely used across multiple industries for machinery diagnostics and health monitoring. Its main applications include:

-

Turbine Monitoring (Steam & Gas)

Accurate vibration and position monitoring of rotors in power generation and petrochemical turbines. -

Compressor Vibration Monitoring

Ideal for measuring shaft movement in centrifugal and reciprocating compressors. -

Motor and Generator Condition Monitoring

Detects early mechanical faults such as unbalance, misalignment, and bearing degradation. -

Pump Monitoring

Prevents pump failure by tracking shaft vibration and axial movement. -

Thrust Bearing Wear Detection

Measures shaft axial position to detect thrust bearing degradation or failure. -

Keyphasor® Systems

Supports phase reference for speed and order tracking in rotating equipment.

Product Advantages

-

Proven API 670 Compliance

Meets the stringent API 670 specifications for machinery protection systems in critical applications. -

High Sensitivity & Accuracy

Offers consistent linear output, crucial for real-time monitoring and diagnostics. -

ClickLoc™ Connector System

Ensures secure and vibration-resistant connections, minimizing signal loss or disconnection. -

Rugged Industrial Design

Withstands high temperatures, harsh environments, and continuous operation. -

Modular Design

Compatible with various 3300 XL series Proximitor Sensors and extension cables for system flexibility. -

Maintenance-Friendly

Easy to install, replace, and calibrate, reducing machine downtime and maintenance costs.

Frequently Asked Questions (FAQ)

1. What does the part number 330101-00-12-05-02-00 indicate?

It refers to a Bently Nevada 3300 XL 8mm probe with a 12-foot cable, 1/4-28 UNF thread, straight connector, and standard configuration without armor.

2. Can this probe be used with all Proximitor sensors?

It is designed to be used specifically with the 3300 XL Proximitor Sensor for optimal performance and accuracy.

3. Is this probe suitable for high-temperature environments?

Yes. It supports operation up to 177°C (350°F), making it ideal for turbines and compressors.

4. What material is the probe calibrated to?

It is factory calibrated to AISI 4140 steel, a common shaft material in industrial equipment.

5. Can this be used for thrust position measurement?

Yes. When mounted axially, it effectively monitors shaft position to track thrust bearing wear.

6. Does it require recalibration over time?

Recalibration is not typically needed unless environmental conditions significantly change or the installation is disturbed.

7. How is the cable terminated?

The probe uses a ClickLoc™ coaxial connector which ensures a secure and tool-free connection to the extension cable.

8. What is the recommended gap between the probe and shaft?

The nominal gap is 1.0 mm (40 mils), adjustable during installation to suit target material and desired output.

9. How do I identify cable length from the part number?

The third and fourth digits (00-12) refer to the 12-foot length of the probe cable.

10. What is the typical output signal of this probe?

It provides a voltage output of approximately -200 mV/mil (≈ -7.87 mV/μm), linear over its full range.

Related Models – Same Series or Function

| Model Number | Description | Tip Size | Cable Length | Thread Size |

|---|---|---|---|---|

| 330101-00-10-10-02-00 | 3300 XL 8mm Probe, 10 ft cable, armored | 8 mm | 10 ft | M10x1 |

| 330101-00-15-10-02-00 | 3300 XL 8mm Probe, 15 ft cable, armored | 8 mm | 15 ft | M10x1 |

| 330105-02-12-10-02-00 | Reverse Mount 8mm Probe, 12 ft | 8 mm | 12 ft | M10x1 |

| 330103-00-12-10-02-00 | 5mm Compact Probe, 12 ft | 5 mm | 12 ft | M8x1 |

| 330104-00-10-10-02-00 | High Temp 8mm Probe, 10 ft | 8 mm | 10 ft | M10x1 |

| 3300 XL NSv Probe | Narrow Side View Probe, variable length | 5 mm | Varies | N/A |

Popular Bently Nevada Models

| Model Number | Function | Application | Series | Mounting |

|---|---|---|---|---|

| 3500/42M | Vibration Monitor Module | Machinery Protection System | 3500 Series | Rack Mounted |

| 330180-90-00 | Proximitor Sensor | Probe Signal Processing | 3300 XL | Panel / DIN Rail |

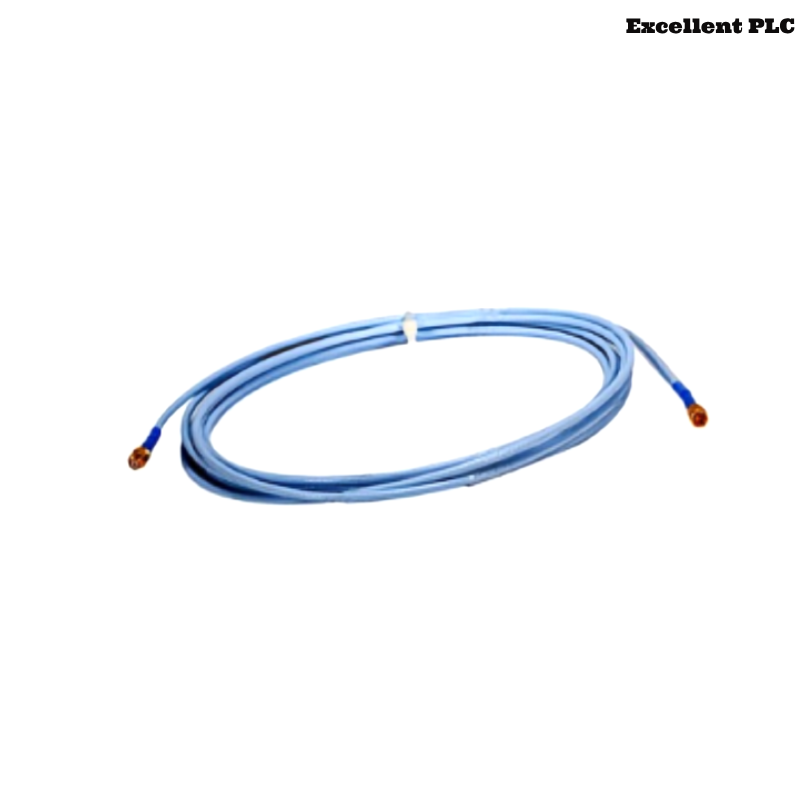

| 330130-040-00 | 10 ft Extension Cable | Connects probe to sensor | 3300 XL | Inline |

| 330500-02-00 | Seismic Velocity Sensor | Seismic Vibration Measurement | 330500 Series | Base-Mounted |

| 330101-00-10-10-02-00 | 8mm Standard Probe, 10 ft | General Shaft Vibration Monitoring | 3300 XL | Threaded Mount |

| 190501-00-00 | Accelerometer | Machine Vibration Monitoring | Seismic Series | Stud or Adhesive Mount |

Excellent PLC

Excellent PLC