| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

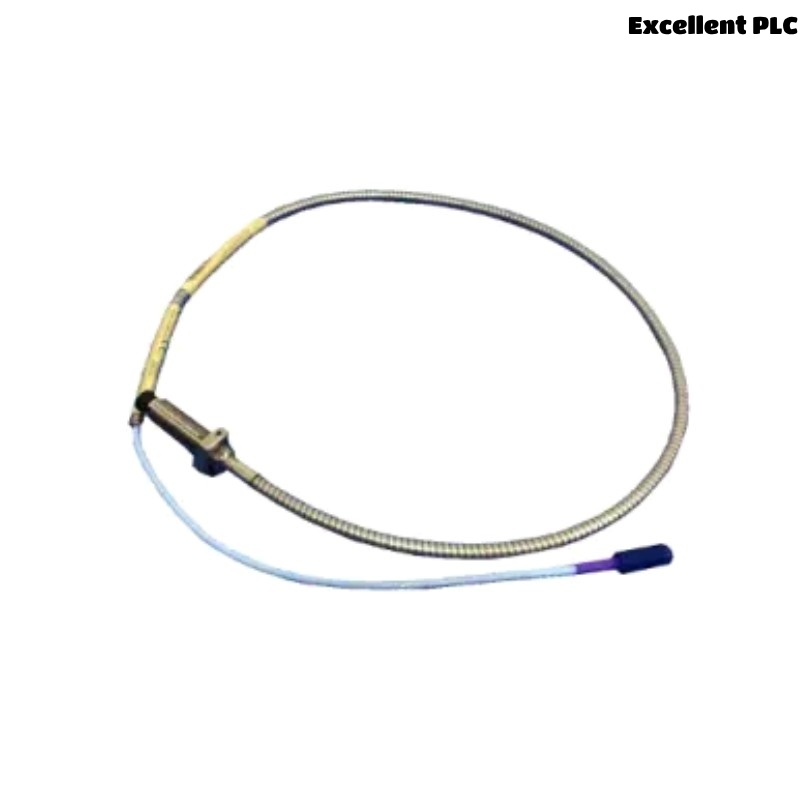

The Bently Nevada 330101-00-12-10-01-CN is part of the 3300 XL 8 mm Proximity Transducer System, a high-performance solution for non-contact measurement of shaft position, vibration, and phase reference. Designed and manufactured by Bently Nevada, a division of Baker Hughes, this probe is widely trusted in industries where reliable machinery protection and condition monitoring are essential.

The 3300 XL 8 mm system is known for its robustness, long-term stability, and compliance with the API 670 standard. It consists of a probe, extension cable, and proximitor sensor. The 330101 probe is specifically engineered for long service life in harsh environments, such as power generation, oil & gas, refining, and industrial manufacturing sectors.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | 3300 XL 8 mm Proximity Probe |

| Model Number | 330101-00-12-10-01-CN |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Tip Diameter | 8 mm |

| Thread Type | 3/8-24 UNF |

| Total Length | 1.0 meters |

| Target Material | 4140 steel or equivalent per API 670 |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Mounting Option | Jam nut or bracket mounting |

| Environmental Rating | IP68 |

| Standard Compliance | API 670, CE, RoHS |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| System Linear Range | 2 mm (80 mils) |

| Usable Gap Range | 0.25 to 2.25 mm |

| Weight | 0.246 kg |

Applications

The Bently Nevada 330101 8 mm Proximity Probe is extensively applied in environments requiring precise shaft monitoring. Common applications include:

-

Steam Turbines – Shaft vibration and position tracking.

-

Gas Turbines – Ensuring alignment and avoiding mechanical contact.

-

Centrifugal Compressors – Vibration analysis and condition monitoring.

-

Electric Motors and Generators – Detecting unbalance or misalignment.

-

Pumps and Fans – Monitoring bearing wear and vibration patterns.

-

Industrial Gearboxes – Evaluating gear mesh alignment and torque behavior.

Its robust construction and sensitivity make it ideal for predictive maintenance systems and critical rotating machinery where failure could lead to substantial losses or downtime.

Advantages

-

API 670 Compliance: Fully adheres to industry standards for machinery protection systems.

-

High Sensitivity & Accuracy: Delivers accurate measurements with minimal drift over time.

-

Durable Construction: Designed for extended use in harsh industrial environments.

-

Flexible Installation: Various thread lengths and mounting options allow for wide adaptability.

-

Environmental Protection: IP68-rated design enables use in submerged or high-contaminant areas.

-

Proven Reliability: Backed by decades of proven field performance in global industries.

-

Compatibility: Seamlessly integrates with 3300 XL extension cables and proximitor sensors.

-

Temperature Tolerance: Operates effectively in high-temperature and vibration-prone areas.

-

Corrosion Resistant: Made from materials resistant to oil, water, chemicals, and corrosion.

-

Extended Lifecycle: Engineered for long-term monitoring without frequent replacement.

Frequently Asked Questions (FAQ)

-

What does the “8 mm” in this probe mean?

It refers to the tip diameter of the probe, which determines the target size and measurement range. -

Is the probe suitable for high-temperature environments?

Yes, it operates safely up to +177°C and stores up to the same temperature range. -

What systems is this probe compatible with?

It is compatible with the Bently Nevada 3300 XL series transducer system, including extension cables and Proximitor sensors. -

Can this be used underwater or in high-dust areas?

Yes, the probe is IP68-rated for complete dust protection and prolonged water immersion. -

How is the probe mounted?

It can be installed using a jam nut on the threaded section or with a mounting bracket. -

What target materials are best for accurate measurements?

The probe is calibrated for 4140 steel, the standard material in most machinery. -

What type of signal output does it produce?

It produces a voltage output proportional to the distance from the target, with 200 mV/mil sensitivity. -

Is the cable detachable or fixed?

This probe connects via a standard extension cable to the proximitor sensor, and is not hardwired. -

How long is the probe’s lifecycle?

With proper installation and within environmental limits, it can last for years without degradation. -

Does the probe require recalibration?

Recalibration is not typically required unless the target material changes or drift is observed in readings.

Related Models (Same Series or Compatible)

| Model Number | Description | Tip Diameter | Cable Length | Thread Length |

|---|---|---|---|---|

| 330101-00-05-10-01 | 8 mm Probe, 0.5 in thread, 5 ft cable | 8 mm | 5 ft | 0.5 in |

| 330101-00-20-10-01 | 8 mm Probe, 2.0 in thread, 10 ft cable | 8 mm | 10 ft | 2.0 in |

| 330101-00-12-05-01 | 8 mm Probe, 0.5 in thread, 12 ft cable | 8 mm | 12 ft | 0.5 in |

| 330104-00-05-10-01 | 5 mm Probe, 0.5 in thread, 5 ft cable | 5 mm | 5 ft | 0.5 in |

| 330101-00-15-10-01 | 8 mm Probe, 1.5 in thread, 10 ft cable | 8 mm | 10 ft | 1.5 in |

| 330101-00-18-05-01 | 8 mm Probe, 0.5 in thread, 18 ft cable | 8 mm | 18 ft | 0.5 in |

Popular Bently Nevada Models

| Model Number | Description | Function | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/42M | Proximitor Monitor | Shaft Vibration & Position | 100 x 30 x 130 | 0.5 |

| 3300 XL 5 mm Probe | 5 mm Proximity Probe | Shaft Vibration | 60 x 5 x 5 | 0.2 |

| 330130-040-00-00 | Extension Cable (4 m) | Signal Transmission | 4000 x 5 x 5 | 0.25 |

| 330180-91-05 | Proximitor Sensor (5 m cable support) | Converts signal to monitor | 70 x 60 x 25 | 0.3 |

| 3500/22M | Transient Data Interface Module | Communication to external systems | 120 x 30 x 140 | 0.45 |

| 7200-06-05-03-00 | Driver for Probes | Signal Conditioning | 80 x 40 x 30 | 0.4 |

Excellent PLC

Excellent PLC