| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

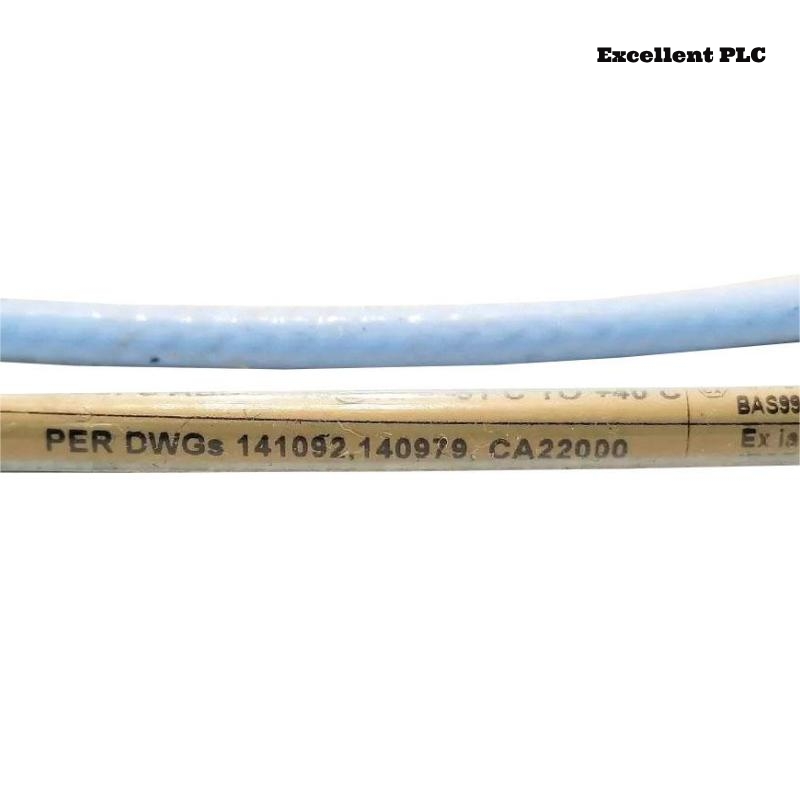

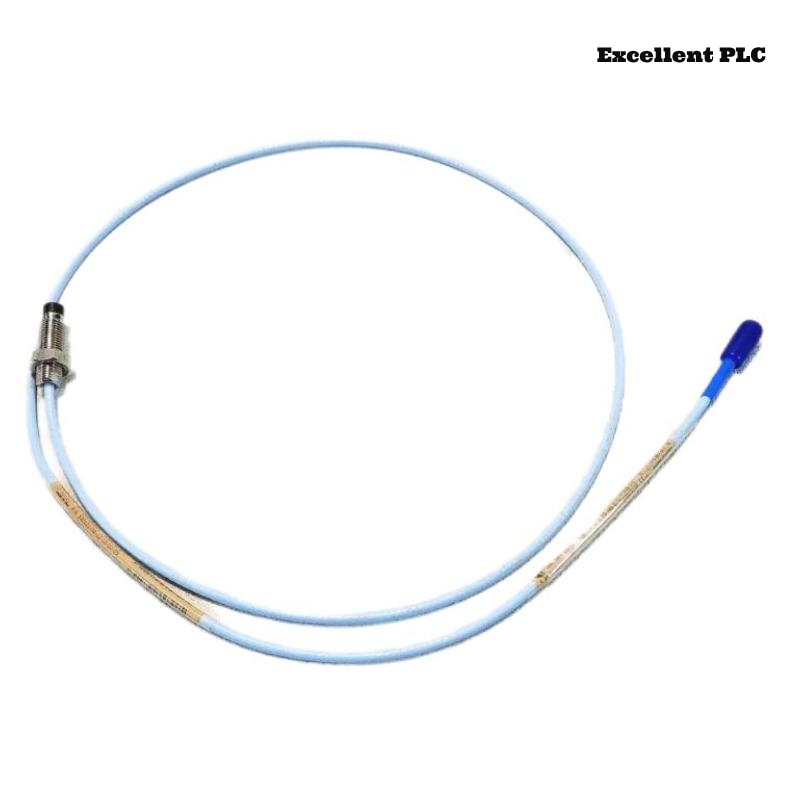

Bently Nevada 330101-00-12-10-02-05 3300 XL 8 mm Probe Overview

The Bently Nevada 3300 XL 8 mm Probe is part of the 3300 XL proximity transducer system, primarily used for vibration and position measurements on fluid-film bearing machines. This system measures both static (position) and dynamic (vibration) values with high precision. It is widely used in applications such as Keyphasor reference and speed measurements, ensuring superior performance for industrial machinery condition monitoring.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330101-00-12-10-02-05 |

| Probe Diameter | 8 mm |

| Total Length | 1.0 meter |

| Weight | 0.323 kg (323 grams) |

| Nominal Probe DC Resistance | 7.59 ± 0.50 ohms (for 1 meter length) |

| Output Resistance | 50 Ω |

| Power Supply | -17.5 Vdc to -26 Vdc |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap Setting | -9 Vdc (approximately 1.27 mm) |

| Environmental Operating Temperature | -52°C to +177°C (standard) |

| Extended Temperature Range | -52°C to +218°C (for probes) |

| Frequency Response | 0 to 10 kHz (+0, -3 dB) |

Applications

The 3300 XL 8 mm Probe is designed for various industrial applications, including:

-

Vibration and Position Measurement: For machinery with fluid-film bearings, it provides accurate readings for the health and stability of rotating equipment.

-

Keyphasor Reference Measurements: Used for rotational speed and phase angle monitoring.

-

Overspeed Protection: Essential in monitoring critical machinery like turbines to prevent damage due to excessive speed.

-

Oil and Gas Industries: Meets API 670 standards for mechanical configuration, linear range, accuracy, and temperature stability.

Advantages

-

Superior Durability: The robust design, including a Polyphenylene Sulfide (PPS) probe tip, offers enhanced resistance against wear and corrosion.

-

High Accuracy: The system offers precise measurements within a linear range of up to 2 mm, with high sensitivity.

-

Interchangeability: Fully compatible and interchangeable with other 3300 XL 5 mm and 8 mm probes, extension cables, and proximitor sensors.

-

Reduced Installation Complexity: The ClickLoc connectors simplify installation, requiring only finger-tight torque for secure connections.

-

Extended Temperature Range: The probe operates effectively in extreme temperatures, from -52°C to +177°C, with an extended temperature range option for more demanding environments.

-

Compliance with Industry Standards: Fully adheres to API 670 for mechanical configuration and performance, ensuring reliable operation in critical applications.

-

Flexible Cable Options: Available with standard and FluidLoc cable options to prevent fluid leakage from the system, ideal for harsh operating conditions.

-

Minimized Maintenance: The design minimizes the need for frequent calibration or replacement, ensuring long-term reliability.

Latest Reports

-

“Bently Nevada 3300 XL 8 mm Probe Achieves High Performance for Rotating Machinery Monitoring”

-

“New Features of Bently Nevada 3300 XL: Key Enhancements in Proximity Sensing”

-

“How the 3300 XL Series Improves Vibration Monitoring in High-Temperature Environments”

-

“Reducing Costs and Complexity with Bently Nevada 3300 XL Proximity Probes”

FAQ

-

What is the maximum temperature for the 3300 XL 8 mm Probe?

-

The standard operating temperature is -52°C to +177°C, with an extended version available for temperatures up to +218°C.

-

-

What applications can benefit from the 3300 XL 8 mm Probe?

-

It is ideal for vibration and position measurements on fluid-film bearing machines, speed monitoring, and overspeed protection.

-

-

How is the 3300 XL Probe mounted?

-

The probe is mounted using a 3/8-24 UNF or M10x1 thread, depending on the model configuration.

-

-

Can the probe be used in hazardous areas?

-

Yes, it complies with hazardous area certifications like ATEX, IECEx, and CSA for use in explosive environments.

-

-

What is the standard length of the probe cable?

-

The cable comes in lengths of 0.5 meters, 1 meter, 1.5 meters, 2 meters, 3 meters, and up to 9 meters.

-

-

Is the 3300 XL 8 mm Probe compatible with older Bently Nevada probes?

-

Yes, it is electrically and physically interchangeable with non-XL 3300 series probes.

-

-

What is the maximum recommended gap setting for vibration measurements?

-

The recommended gap setting is -9 Vdc (approximately 1.27 mm).

-

-

How does the probe maintain signal integrity?

-

The probe uses gold-plated ClickLoc connectors and is highly immune to radio frequency interference (RFI).

-

-

Can I use the probe with extended temperature range (ETR) cables?

-

Yes, the probe is compatible with ETR extension cables that operate in temperatures up to 260°C.

-

-

What is the recommended minimum shaft diameter for mounting the probe?

-

The minimum recommended shaft diameter is 50.8 mm (2 inches) for proper performance.

Related Models

| Model Number | Description |

|---|---|

| 330102 | 3300 XL 8 mm Probe with Armor |

| 330191 | 3300 XL 8 mm ETR Probe |

| 330180 | 3300 XL Proximitor Sensor |

| 330130 | 3300 XL Standard Extension Cable |

| 330105 | 3300 XL Reverse Mount Probe |

| 330106 | 3300 XL M10 Reverse Mount Probe |

| 330140 | 3300 XL 8 mm Smooth Case Probe |

| 330141 | 3300 XL 8 mm Smooth Case Probe with Armor |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3300 5 mm | 3300 Series Proximity Probe |

| 3300 5 mm XL | Extended Length 3300 Series Probe |

| 3500/42 | Vibration Monitoring System |

| 3500/72 | Dynamic Pressure Monitoring System |

| 3300 8 mm | Standard 3300 Series Probe |

| 3300 8 mm XL | Extended Length 3300 Series Probe |

| 3500/33 | Proximity Transducer System |

| 3500/40 | Vibration Transducer System |

Excellent PLC

Excellent PLC