| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

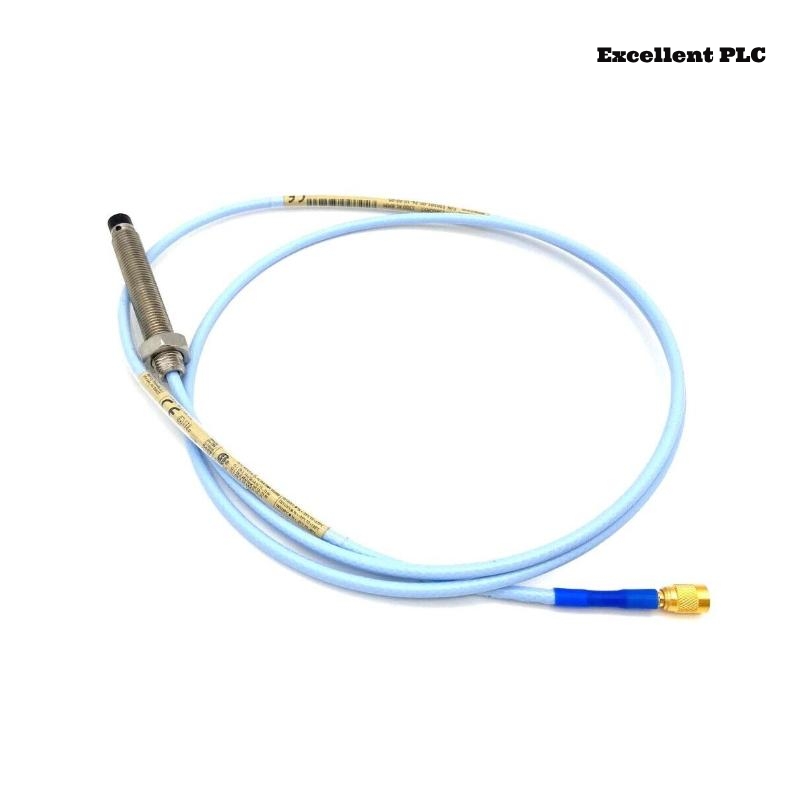

Product Description: Bently Nevada 3300 XL 8 mm Probe (330101-00-19-10-02-00)

The Bently Nevada 3300 XL 8 mm Proximity Transducer System includes a probe, extension cable, and proximitor sensor. It is designed for highly accurate vibration and position measurement in applications such as fluid-film bearing machines, Keyphasor reference, and speed measurements. This system is known for its advanced performance and is compliant with the American Petroleum Institute (API) 670 standards for mechanical configuration, linear range, accuracy, and temperature stability. It provides an output voltage proportional to the distance between the probe tip and a conductive surface, enabling reliable dynamic and static measurements.

The 3300 XL 8 mm probe is a rugged, high-precision device suitable for demanding industrial environments, supporting both static position and dynamic vibration measurements. It features superior performance, improved immunity to interference, and offers compatibility with older models in the 3300 series, making it a versatile solution for various applications.

Product Parameters

| Specification | Details |

|---|---|

| Model | 3300 XL 8 mm Probe (330101-00-19-10-02-00) |

| Total Length | 1.0 meter (3.3 feet) |

| Weight | 0.323 kg (0.71 lbs) |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Probe Case Material | AISI 303 or 304 stainless steel (SST) |

| Probe Cable Specifications | 75Ω triaxial, FEP insulated (standard cable) |

| Maximum Probe Temperature | -52°C to +177°C (-62°F to +350°F) |

| Extended Temperature Range | Up to 218°C (425°F) for the probe tip and 260°C (500°F) for the cable |

| Minimum Shaft Diameter | 50.8 mm (2 inches) |

| Minimum Target Size | 15.2 mm (0.6 in) diameter (flat target) |

| Linear Range | 2 mm (80 mils) |

| Gap Setting for Radial Vibration | -9 Vdc (1.27 mm or 50 mils) |

| Incremental Scale Factor | 7.87 V/mm (200 mV/mil) ± 5% over 80 mil linear range |

| Extension Cable Resistance | 0.66 Ω to 1.65 Ω depending on length |

| Frequency Response | 0 to 10 kHz, +0, -3 dB |

| Connector Type | Miniature coaxial ClickLoc |

Product Applications

-

Vibration Measurement: Ideal for dynamic vibration measurements on rotating machinery such as turbines and compressors.

-

Position Sensing: Used to measure radial and axial positions in fluid-film bearing machines.

-

Keyphasor Reference: Enables accurate measurement of shaft speed and rotational position.

-

Fluid-Film Bearing Machines: Specifically designed for critical monitoring in these environments.

-

Tachometer/Overspeed Protection: Effective in applications requiring precise tachometer or overspeed protection measurements.

Product Advantages

-

Interchangeability: Fully interchangeable with non-XL 3300 series 5 mm and 8 mm components, ensuring compatibility with older systems.

-

Advanced Performance: Provides exceptional accuracy and stability, even in harsh environments.

-

Low Installation Cost: The ClickLoc connectors and robust wiring reduce installation time and complexity.

-

Wide Temperature Range: Offers extended temperature capabilities, making it suitable for challenging operational conditions.

-

Improved RFI/EMI Immunity: Immune to interference from radio frequencies, which enhances reliability in industrial settings.

-

Durability: The rugged probe design ensures long-lasting performance in harsh environments, minimizing downtime.

-

Backward Compatibility: Backward compatible with older non-XL probes and sensors, reducing the need for full system replacements.

FAQ

-

What is the typical application for the 3300 XL 8 mm Probe?

-

It is used for vibration and position measurements on rotating machinery and fluid-film bearing systems.

-

-

Can this probe be used for both static and dynamic measurements?

-

Yes, the 3300 XL 8 mm probe can measure both static position and dynamic vibration values.

-

-

What is the maximum operating temperature of the 3300 XL 8 mm Probe?

-

The probe can operate up to 177°C (350°F) with the standard model and up to 218°C (425°F) for extended temperature range versions.

-

-

How does the 3300 XL system achieve its high accuracy?

-

The system features a linear range from 0.25 mm to 2.3 mm and maintains an incremental scale factor with minimal deviation, ensuring precise measurements.

-

-

Is the 3300 XL 8 mm Probe compatible with older systems?

-

Yes, the components are compatible with previous 3300 series probes, ensuring seamless integration into legacy systems.

-

-

Can I use this probe in hazardous areas?

-

Yes, the probe and associated components comply with hazardous area approvals, including ATEX, IECEx, and other global standards.

-

-

What materials can the 3300 XL 8 mm Probe measure?

-

The probe is factory calibrated to AISI 4140 steel but can be recalibrated for other materials upon request.

-

-

What are the power requirements for the 3300 XL Proximitor Sensor?

-

It requires a -17.5 Vdc to -26 Vdc power supply with a maximum current consumption of 12 mA.

-

-

How does the probe’s connector ensure secure installation?

-

The ClickLoc connector system provides secure connections without requiring tools, reducing installation time.

-

-

Can the system be used in high-vibration environments?

-

Yes, the 3300 XL system is designed for high-vibration applications, offering precise and stable measurements in such environments.

-

Recommended Models from the 3300 Series

| Model | Description | Features |

|---|---|---|

| 330101 | 3300 XL 8 mm Probe | Standard model for general applications |

| 330102 | 3300 XL 8 mm Probe with Armor | Enhanced durability for harsh environments |

| 330105 | 3300 XL 8 mm Reverse Mount Probe | For reverse mounting applications |

| 330106 | 3300 XL 8 mm Reverse Mount Probe with Armor | For rugged environments with reverse mounting |

| 330140 | 3300 XL 8 mm Smooth Case Probe | Standard model with smooth case design |

| 330191 | 3300 XL 8 mm Extended Temp Probe | For applications with extreme temperatures |

| 330193 | 3300 XL 8 mm ETR Probe | Extended temperature range for critical settings |

| 330194 | 3300 XL 8 mm ETR Probe with Armor | Enhanced protection for high-temperature uses |

Popular Models from Bently Nevada

| Model | Description | Features |

|---|---|---|

| 3300 5 mm | 3300 Series 5 mm Proximity Probe | Smaller size for tight installations |

| 3300 8 mm | 3300 Series 8 mm Proximity Probe | Standard model for general applications |

| 330701 | Bently Nevada Vibration Transducer | For high-precision vibration monitoring |

| 3500/22M | 3500 Series Machinery Protection System | Comprehensive machine protection system |

| 3500/42M | 3500 Series Power Supply | Reliable power supply for monitoring systems |

| 3500/44M | 3500 Series Tachometer Module | High-accuracy tachometer for rotational speed |

| 3500/33 | 3500 Series Vibration Monitor | Vibration monitoring for rotating equipment |

| 330010 | 3300 Proximitor Sensor | Versatile sensor for vibration and position measurement |

Excellent PLC

Excellent PLC