| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

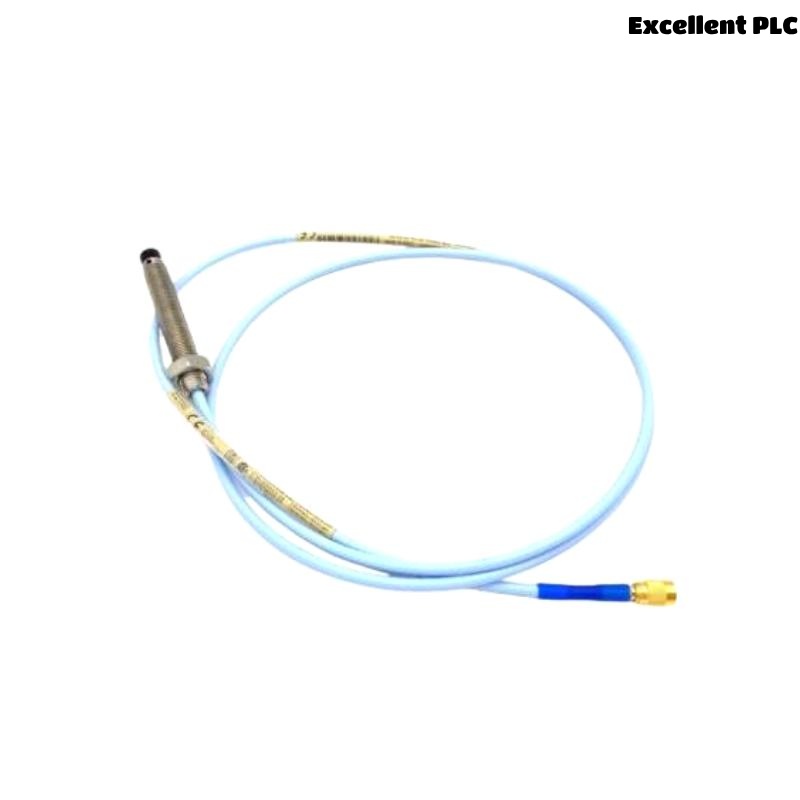

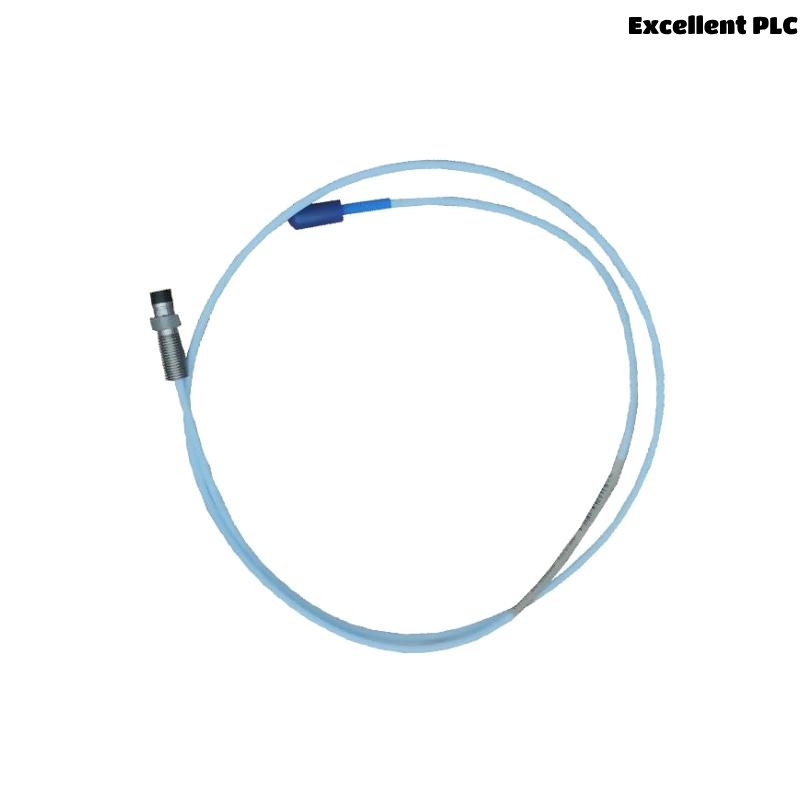

The Bently Nevada 330101-00-20-10-01-05 proximity probe is part of the trusted 3300 XL series, widely recognized for its reliable performance in industrial machinery vibration monitoring and shaft position measurement. This 8 mm probe is engineered to deliver precise and stable readings in demanding environments, supporting maintenance and protection of critical rotating equipment.

Manufactured with high-quality materials and designed according to API 670 standards, the 330101-00-20-10-01-05 model ensures long-lasting operation even in extreme temperature, pressure, and vibration conditions. Its compatibility with the Bently Nevada 3300 XL system and related accessories guarantees seamless integration into existing monitoring setups.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-20-10-01-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm (0.31 inches) |

| Thread Size | 3/8-24 UNF-2A |

| Connector Type | Molded miniature coaxial connector |

| Total Length | 1 meter |

| Sensing Range | 2 mm (80 mils) linear range |

| Operating Temperature | -51°C to +177°C (-60°F to +350°F) |

| System Accuracy | ±0.127 mm (±5 mils) or better |

| Housing Material | Stainless steel (AISI 303/304) |

| Weight | 0.323 kg |

| Mounting Method | Threaded mounting or clamp |

| Compliance Standards | API 670 compliant |

Product Applications

The 330101-00-20-10-01-05 proximity probe is primarily used for condition monitoring and protection of rotating machinery in critical industrial sectors. Its key application areas include:

-

Steam and Gas Turbines: Shaft vibration and position monitoring to prevent catastrophic failures.

-

Compressors: Axial and radial position sensing in both centrifugal and axial compressors.

-

Pumps: Monitoring shaft displacement to detect early signs of mechanical issues.

-

Motors and Generators: Protection through vibration monitoring and shaft position feedback.

-

Industrial Gearboxes: Monitoring for wear, misalignment, and shaft stability.

-

Fans and Blowers: Continuous condition assessment for maintenance scheduling.

This probe is crucial for facilities such as power plants, oil and gas refineries, chemical plants, and large-scale manufacturing plants, helping to improve machinery uptime, optimize maintenance, and avoid unplanned downtime.

Product Advantages

-

Robust Construction: Stainless steel body designed to withstand harsh industrial environments including corrosive atmospheres.

-

Wide Operating Temperature: Performs reliably across a broad temperature range, accommodating many industrial conditions.

-

API 670 Compliance: Ensures the probe meets stringent industry standards for machinery protection.

-

Precision and Stability: Provides consistent, linear measurements with high accuracy to enable reliable diagnostics.

-

Ease of Installation: Standardized mounting and connector options simplify integration with existing systems.

-

Long Service Life: Resistant to vibration, shock, and contamination for extended operational lifespan.

-

Compatibility: Seamlessly works with 3300 XL Proximitor sensors and extension cables.

-

Reduced Downtime: Early fault detection capability supports predictive maintenance strategies.

Frequently Asked Questions (FAQ)

-

What does the 330101-00-20-10-01-05 probe measure?

It measures the displacement and vibration of rotating shafts to monitor machinery health. -

What is the sensing range of this probe?

It has a linear sensing range of 2 mm (80 mils). -

Can the probe withstand high temperatures?

Yes, it operates between -51°C and +177°C (-60°F to +350°F). -

What materials are used in the probe housing?

The housing is made of stainless steel (AISI 303/304) for durability and corrosion resistance. -

Is this probe compatible with Bently Nevada 3300 systems?

Yes, it is designed for full compatibility with the 3300 XL system components. -

How is the probe mounted?

It uses a 3/8-24 UNF threaded mounting, or can be installed with a clamp assembly. -

Does the probe require calibration?

The probe is factory-calibrated and typically does not require field calibration. -

What connector type does this probe use?

It uses a molded miniature coaxial connector. -

How long is the standard cable on this probe?

It comes with a 1 meter cable. -

Can this probe be used for thrust position monitoring?

Yes, it is suitable for both radial and axial shaft position monitoring.

Related Models (Same Series or Similar)

| Model Number | Description | Cable Length | Tip Diameter | Use Case |

|---|---|---|---|---|

| 330101-00-20-10-01-00 | 3300 XL 8 mm Proximity Probe | 10 ft | 8 mm | Standard XL probe |

| 330101-00-25-10-01-05 | 8 mm XL Probe with longer thread length | 10 ft | 8 mm | Extended thread mounting |

| 330101-00-30-10-01-05 | 8 mm XL Probe with 3-inch thread length | 10 ft | 8 mm | Deep bore applications |

| 330130-040-00-00 | 3300 XL Extension Cable | 4 m | N/A | Extension for probe systems |

| 330104-00-08-10-02-00 | Reverse Mount 3300 XL Probe | 8 in | 8 mm | Reverse mounting applications |

| 330106-05-30-10-02-00 | Ceramic Tip Probe for harsh environments | 5 in | 8 mm | High durability requirements |

Popular Bently Nevada Models

| Model Number | Description | Application | Key Feature |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Machinery protection systems | High-speed data interface |

| 3500/42M | Proximitor/Seismic Monitor | Vibration and seismic monitoring | Combined sensor monitoring |

| 3500/15 | Power Supply Module | Powering 3500 system modules | Stable power supply |

| 1900/65A | Vibration Monitor for Balance of Plant | Standalone vibration monitor | Compact and reliable |

| 330500 | Velocity Sensor | Low-frequency vibration sensing | Velocity measurement |

| 7200 Series | Legacy Monitoring System | Turbine and compressor systems | Proven reliability |

Excellent PLC

Excellent PLC