| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

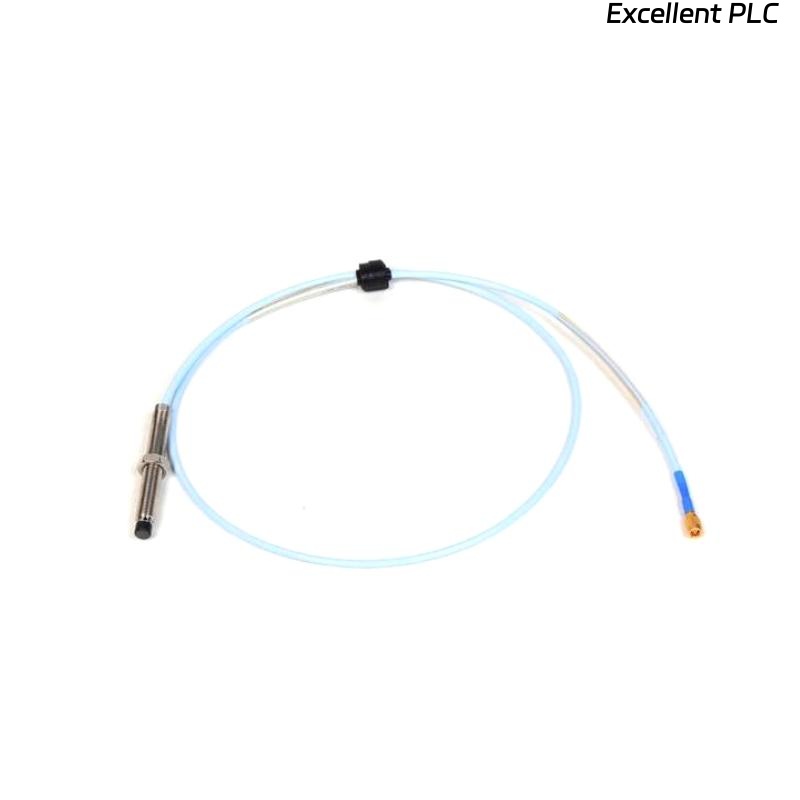

The Bently Nevada 330101-00-20-10-02 3300 XL 8mm Proximity Probe is a high-performance proximity sensor designed for industrial condition monitoring and machinery protection systems. It belongs to the Bently Nevada 3300 XL series, widely recognized for its reliability in harsh environments. The probe measures the distance between the probe tip and the target surface, primarily used for detecting shaft vibration, rotor position, and axial displacement. The advanced XL design ensures superior immunity to radio frequency interference (RFI) and electromagnetic interference (EMI), which is critical in electrically noisy environments such as power plants, refineries, and heavy machinery operations.

The 330101-00-20-10-02 probe is engineered for seamless compatibility with Bently Nevada Proximitor sensors and extension cables, creating a complete proximity measurement system. It uses an eddy-current principle to deliver accurate non-contact measurements, making it an essential component in predictive maintenance strategies.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330101-00-20-10-02 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Measurement Range | 0.25 mm to 2.0 mm |

| Linear Range | 80 mils (2.0 mm) |

| Frequency Response | 0 to 10 kHz |

| Temperature Range | -35°C to +177°C |

| Total Length | 1 meter |

| Connection Type | Miniature coaxial connector |

| Material | Stainless Steel housing |

| Weight | 0.323 kg |

| Mounting Thread | M10 x 1.0 (standard) |

| Compatible Systems | Bently Nevada 3300 XL Proximitor Sensors and extension cables |

| Compliance | API 670, CE certified |

Product Applications

The 330101-00-20-10-02 probe is used extensively across various industries where machinery reliability and condition monitoring are crucial:

-

Power Generation: Monitoring turbine and generator shaft vibration.

-

Oil & Gas: Condition monitoring for compressors, pumps, and critical rotating equipment.

-

Petrochemical: Detecting rotor position in refining and chemical processing machinery.

-

Steel & Mining: Protecting heavy-duty industrial machines from catastrophic failures.

-

Manufacturing: Ensuring smooth operation of high-speed machinery and motors.

-

Pulp & Paper: Vibration monitoring for rollers and rotating assets.

Product Advantages

-

Enhanced RFI/EMI Immunity: Designed to perform reliably in electrically noisy environments.

-

Extended Operating Temperature: Handles a broad temperature range for harsh industrial conditions.

-

API 670 Compliance: Meets industry standards for vibration monitoring and machine protection.

-

Modular System Design: Easily integrates with Proximitor sensors and extension cables for flexible configurations.

-

Non-Contact Measurement: Reduces wear and tear, ensuring long-term stability.

-

Durable Construction: Stainless steel housing for corrosion resistance and rugged operation.

FAQ

1. How does the 330101-00-20-10-02 measure vibration?

The probe uses the eddy-current principle to detect changes in distance between the probe tip and the target, translating displacement into a voltage signal.

2. What is the standard linear range of this proximity probe?

It offers a linear range of approximately 80 mils (2.0 mm) for accurate measurements.

3. Can this probe be used in high-temperature environments?

Yes, it supports operation in temperatures ranging from -35°C to +177°C.

4. Which Proximitor sensors are compatible with this probe?

It is fully compatible with Bently Nevada 3300 XL Proximitor Sensors and corresponding extension cables.

5. What type of mounting thread does this probe use?

The standard mounting thread is M10 x 1.0, suitable for most industrial applications.

6. Does this probe comply with API 670 standards?

Yes, it meets API 670 requirements for machine protection systems.

7. How is signal integrity maintained over long cable lengths?

The system uses a matched probe, extension cable, and Proximitor sensor configuration to maintain accuracy and minimize signal degradation.

8. Can it be installed in areas with high electromagnetic interference?

Yes, its XL design offers superior EMI/RFI immunity for such environments.

9. What is the frequency response of this probe?

The probe supports a frequency response from 0 to 10 kHz, ensuring accurate vibration detection.

10. Is this probe suitable for axial displacement measurements?

Yes, it is widely used for both radial vibration and axial position measurements in rotating machinery.

Related Models (Same Series or Similar Functionality)

| Model Number | Description |

|---|---|

| 330102-00-05-10-02 | 3300 XL 11mm Proximity Probe |

| 330103-00-10-10-02 | 3300 XL 5mm Proximity Probe |

| 330104-00-20-10-02 | 3300 XL Reverse Mount Probe |

| 330130-040-00 | 3300 XL Extension Cable |

| 330106-05-30-10-02 | High-Temperature 8mm Probe |

| 330171-XX-XX-XX | 3300 XL Standard Extension Cable |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/22M | Transient Data Interface Module |

| 3500/42M | Proximitor/Seismic Monitor |

| 3500/15 | Power Supply Module |

| 3500/40M | Vibration Monitor |

| 330500 | Velomitor Piezo-Velocity Sensor |

| 330780-91-00 | Bently Nevada Accelerometer |

Excellent PLC

Excellent PLC