| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

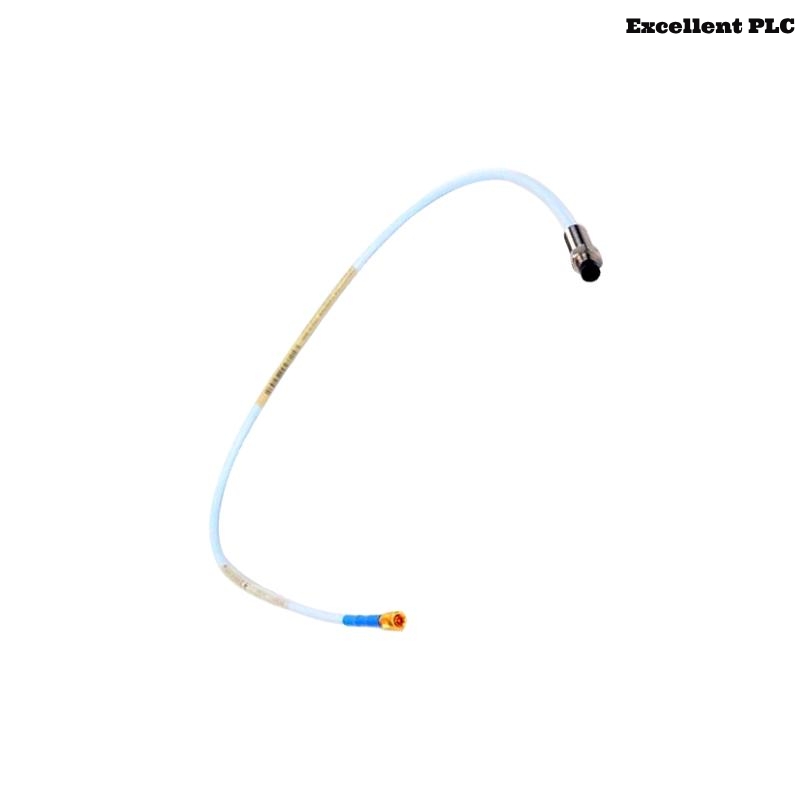

The Bently Nevada 330101-00-20-10-11-00 is a part of the renowned 3300 XL series proximity transducer systems developed by Baker Hughes’ Bently Nevada division. Designed specifically for industrial vibration and position monitoring applications, this particular probe offers an 8mm tip and is engineered to work reliably in harsh environments such as turbines, compressors, pumps, and other rotating machinery.

The 3300 XL 8mm Proximity Probe provides highly accurate, non-contact measurements of shaft position and vibration. It is particularly known for its long-term stability, rugged construction, and consistent performance across a wide range of temperatures and environmental conditions.

This model includes a probe, extension cable, and proximity sensor (proximitor), and is fully compatible with API 670 standard-compliant monitoring systems. With its backward compatibility with older Bently Nevada systems, the 330101-00-20-10-11-00 remains a preferred choice for system upgrades and new installations alike.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-20-10-11-00 |

| Series | 3300 XL 8mm |

| Measurement Range | 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2.00 mm (10 to 80 mils) |

| System Output | 200 mV/mil (7.87 mV/μm) |

| Probe Tip Diameter | 8 mm (0.315 in) |

| Mounting Thread | 3/8-24 UNF-2A |

| Case Material | AISI 304 Stainless Steel |

| Connector Type | Miniature coaxial |

| Operating Temperature | -51°C to +177°C (-60°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Relative Humidity | 95% non-condensing |

| Ingress Protection | IP68 |

| Weight | 0.323 kg |

| Total Length | 1.0 meter |

Applications

The 330101-00-20-10-11-00 probe is widely used in a range of industrial sectors for real-time monitoring of machinery health and performance. Common applications include:

-

Steam and Gas Turbines

Used for radial and axial position monitoring to prevent failures due to rotor-stator contact. -

Centrifugal Compressors

Monitors shaft displacement and vibration to detect misalignment or imbalance. -

Industrial Pumps

Ensures mechanical integrity and allows for predictive maintenance in fluid movement systems. -

Gearboxes and Motors

Evaluates gear mesh and shaft stability under various load conditions. -

Fans and Blowers

Helps maintain balance and alignment in high-speed rotating systems. -

Critical Bearing Monitoring

Vital for tracking bearing clearances and detecting early signs of wear.

Product Advantages

-

High Accuracy and Stability

Designed to provide precise shaft position and vibration measurements even under extreme conditions. -

Rugged Design

Made of stainless steel and sealed to IP68 standards, the probe offers excellent resistance to harsh environments, oil, dust, and vibration. -

API 670 Compliance

Meets or exceeds industry standards for machinery protection systems, ensuring reliability and safety. -

Backward Compatibility

Easily integrated into existing Bently Nevada systems, facilitating system upgrades without the need for full replacements. -

Wide Operating Range

Performs reliably across broad temperature and pressure ranges, making it suitable for both high- and low-temperature machinery. -

Modular System

Easily paired with extension cables and proximitor sensors to meet application-specific needs.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the 330101-00-20-10-11-00 probe?

A: It measures shaft vibration and position in rotating machinery without making contact. -

Q: Is this probe compatible with older Bently Nevada systems?

A: Yes, it maintains backward compatibility with most legacy Bently Nevada systems. -

Q: Can the probe be used in high-temperature environments?

A: Yes, it supports operating temperatures up to +177°C (+350°F). -

Q: What is the measurement output of this probe?

A: It provides a linear output of 200 mV/mil (7.87 mV/μm). -

Q: Is this probe compliant with API 670 standards?

A: Yes, it is fully compliant with API 670 standards for machinery protection. -

Q: What’s the maximum cable length available?

A: It can be configured with cable lengths up to 9 meters, depending on system design. -

Q: Is the probe resistant to oil and dust?

A: Yes, with its IP68 rating, it is sealed against ingress of oil, dust, and water. -

Q: Does the probe require regular calibration?

A: Routine checks are recommended, but the probe is designed for long-term stability. -

Q: Can this probe be used in underwater applications?

A: Its IP68 rating allows use in wet or submerged environments, depending on installation. -

Q: Is the connector field-replaceable?

A: No, the connector is typically fixed; damaged cables often require full replacement.

Related Models from the Same Series (3300 XL Probes)

| Model Number | Description | Tip Diameter | Cable Type | Output |

|---|---|---|---|---|

| 330101-00-08-10-02-00 | 8mm probe with short cable | 8 mm | 2 m | 200 mV/mil |

| 330103-00-05-10-01-00 | 5mm standard length probe | 5 mm | 1 m | 200 mV/mil |

| 330104-00-10-10-02-00 | 11mm extended temperature probe | 11 mm | 2 m | 200 mV/mil |

| 330105-02-12-10-02-00 | 8mm reverse mount probe | 8 mm | 2 m | 200 mV/mil |

| 330106-05-18-10-05-00 | Long reach proximity probe | 8 mm | 5 m | 200 mV/mil |

| 330108-00-25-10-01-00 | High-vibration compatible probe | 8 mm | 1 m | 200 mV/mil |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Product Type | Description | Application Area |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Condition monitoring data interface module | Machinery Protection System |

| 3500/42M | Proximitor Monitor | 4-channel proximity and axial position monitoring | Critical Turbomachinery |

| 330103-00-05-10-01-00 | 5mm Proximity Probe | Standard proximity probe for tight spaces | Compressors, Fans |

| 3300/16-13-01-01-00 | Dual Vibration Monitor | Vibration monitoring for dual channels | High-speed Motors, Turbines |

| 7200-50-06-02-00 | Proximitor Sensor | Vibration sensor for shaft monitoring | General Industrial Use |

| 86517-01 | Accelerometer | Industrial-grade velocity sensor | Machinery Health Monitoring |

Excellent PLC

Excellent PLC