| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

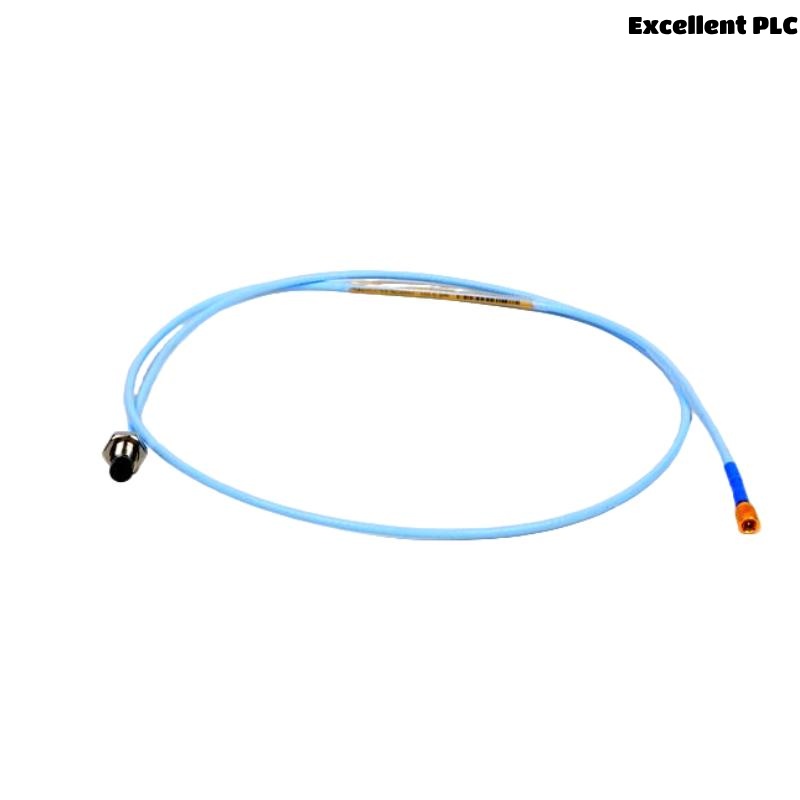

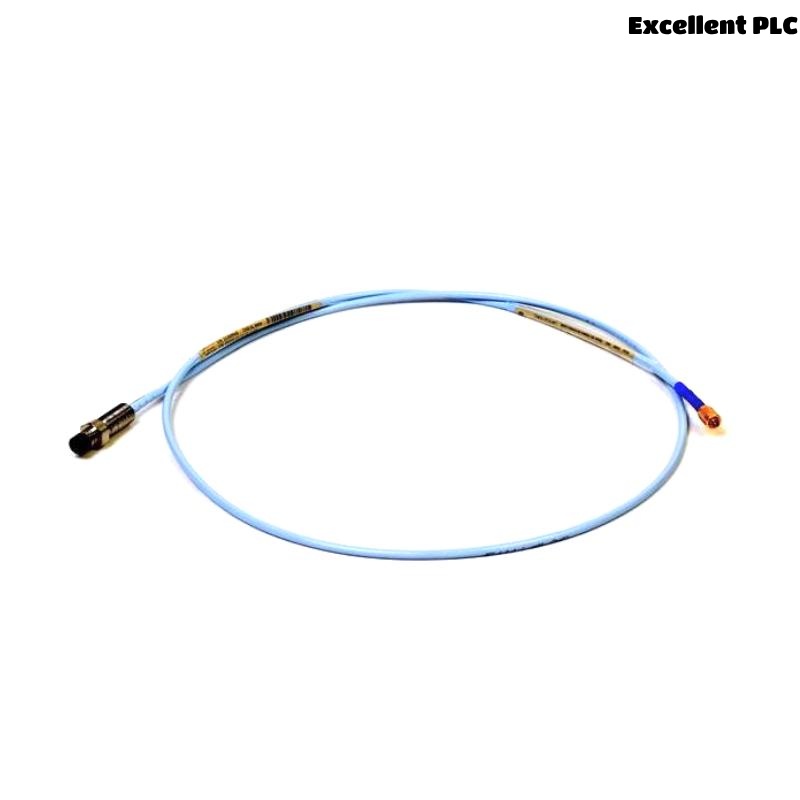

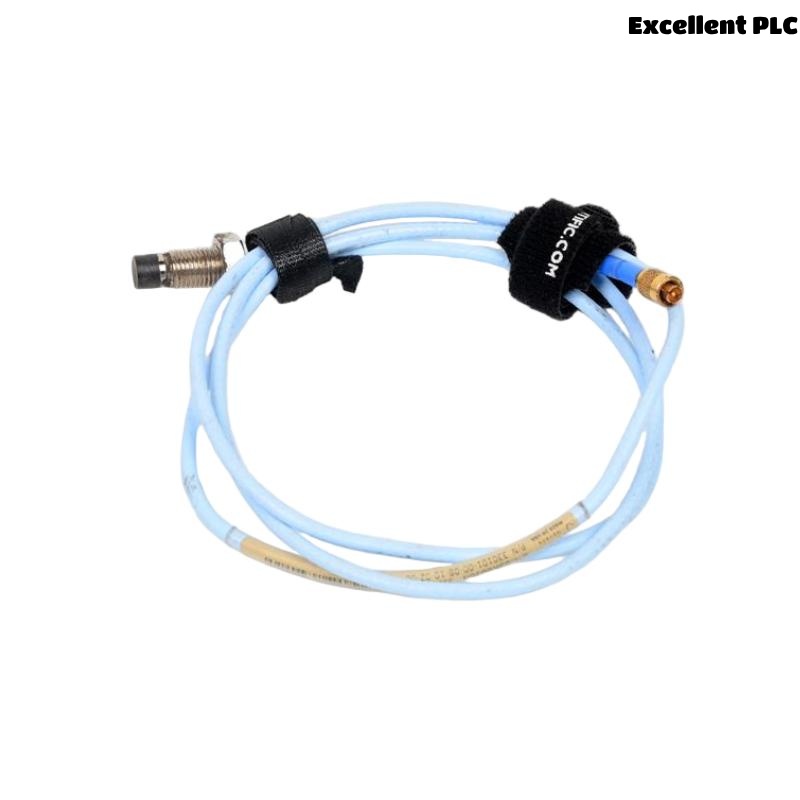

The Bently Nevada 330101-00-20-20-02-05 3300 XL 8mm Proximity Probe is a cutting-edge sensor specifically designed for the precise measurement of shaft displacement and vibration in rotating machinery. This probe is part of Bently Nevada’s 3300 XL Series, which is known for its reliability, accuracy, and durability in harsh industrial environments.

This proximity probe is engineered to deliver high precision and fast response times, enabling real-time monitoring of critical machinery. It is particularly suitable for applications in turbines, compressors, motors, and other rotating machinery where consistent performance and early fault detection are vital for preventing costly downtimes. With a robust stainless-steel construction, the 3300 XL 8mm Proximity Probe ensures long-term, trouble-free operation even in the most demanding conditions.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 330101-00-20-20-02-05 |

| Series | 3300 XL |

| Probe Diameter | 8mm |

| Measuring Range | 0 to 10mm |

| Output Signal | 4-20 mA |

| Sensitivity | ±1% of full scale |

| Response Time | < 1ms |

| Material | Stainless Steel |

| Operating Temperature Range | -40°C to 120°C (–40°F to 248°F) |

| Total Length | 2 meters |

| Weight | 0.646 kg |

| Accuracy | ±0.05% full scale |

| Construction | Rugged stainless steel housing |

| Vibration Range | ±5mm peak-to-peak |

| Application | Turbines, compressors, motors, pumps |

Product Applications

The 3300 XL 8mm Proximity Probe is designed for a variety of industries that rely on the condition monitoring of rotating machinery. Its main applications include:

-

Turbines: Used to monitor the position and vibration of turbine shafts, ensuring operational safety and detecting any misalignment, imbalance, or wear that could cause failure.

-

Compressors: Monitors the shaft position and vibration levels of compressors, helping identify signs of damage or degradation in seals, bearings, or other critical components.

-

Motors: Provides precise measurements of the shaft’s position in motor applications, detecting any movement that could indicate misalignment, imbalance, or bearing failure.

-

Pumps: Helps detect axial and radial vibration in pumps, ensuring that performance remains optimal, and wear is detected early before failure occurs.

-

Industrial Fans: Used to measure shaft displacement and vibrations, which is crucial for maintaining the health of fans in industries where continuous air movement is required.

-

Gearboxes: This probe is also used to monitor the health of gearboxes, tracking shaft displacement to avoid misalignment and other mechanical issues.

Through continuous real-time monitoring, this probe helps minimize downtime and prevent costly repairs or replacements.

Product Advantages

-

High Precision: The 3300 XL 8mm Proximity Probe offers exceptional precision in shaft displacement and vibration measurements. With an accuracy of ±0.05% full scale, it provides reliable and accurate data for machinery health monitoring.

-

Durable Construction: Built with stainless steel, this proximity probe is resistant to corrosion and can withstand extreme temperatures, vibrations, and environmental factors, ensuring longevity and reliability in harsh environments.

-

Low Maintenance: The probe is designed to operate in tough conditions with minimal maintenance requirements, making it cost-effective over its operational life.

-

Real-Time Monitoring: Continuous monitoring allows early detection of faults such as misalignment, imbalance, and bearing wear. This proactive approach helps prevent unplanned downtime and extends the life of the equipment.

-

Wide Operating Range: With an operating temperature range from -40°C to 120°C (-40°F to 248°F), the probe can be used in a variety of industrial applications, including those in extreme environments.

-

Easy Integration: The probe easily integrates with the Bently Nevada 3300 XL Series monitoring system, providing a scalable solution for condition-based maintenance.

-

Enhanced Reliability: With its rugged design and quick response time of less than 1ms, the 3300 XL 8mm Proximity Probe is built for high-performance environments where reliability is crucial.

Frequently Asked Questions (FAQ)

-

What is the measuring range of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The measuring range is 0 to 10mm, making it suitable for a wide range of applications involving shaft displacement and vibration monitoring.

-

-

Can the 3300 XL 8mm Proximity Probe be used in extreme temperatures?

-

Yes, the probe is designed to operate in temperatures ranging from -40°C to 120°C (-40°F to 248°F), which makes it ideal for use in both very cold and hot industrial environments.

-

-

How accurate is the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe offers an accuracy of ±0.05% of full scale, ensuring highly reliable measurements for machinery monitoring.

-

-

What output signal does the 3300 XL 8mm Proximity Probe provide?

-

The probe provides a 4-20 mA output signal, which is standard for many industrial monitoring systems.

-

-

What industries can benefit from using this proximity probe?

-

The probe is ideal for industries such as power generation, oil and gas, manufacturing, and other sectors that rely on the monitoring of rotating machinery.

-

-

How does the 3300 XL 8mm Proximity Probe detect machine faults?

-

By continuously measuring shaft displacement and vibration, the probe helps detect faults like misalignment, imbalance, and bearing wear, allowing for early maintenance actions.

-

-

What materials are used in the construction of the probe?

-

The probe is constructed from durable stainless steel, ensuring that it is resistant to corrosion and capable of withstanding harsh industrial environments.

-

-

What is the weight of the Bently Nevada 3300 XL 8mm Proximity Probe?

-

The probe weighs 0.646 kg, making it lightweight and easy to install while still being robust and durable.

-

-

Can the probe be used in high-vibration environments?

-

Yes, the 3300 XL 8mm Proximity Probe is specifically designed for high-vibration environments and can withstand vibrations up to ±5mm peak-to-peak.

-

-

Is the 3300 XL 8mm Proximity Probe compatible with other Bently Nevada monitoring systems?

-

Yes, the probe is compatible with the 3300 XL Series and can integrate with other Bently Nevada vibration monitoring systems for comprehensive machinery health monitoring.

Recommended Related Models

Here are six related models from the 3300 XL Series that could be of interest:

| Model Number | Description | Measuring Range | Output Signal | Weight |

|---|---|---|---|---|

| 330101-00-20-20-02 | 3300 XL Proximity Probe (5mm) | 0 to 10mm | 4-20 mA | 0.4 kg |

| 330101-00-20-20-03 | 3300 XL Proximity Probe (8mm, Standard) | 0 to 10mm | 4-20 mA | 0.45 kg |

| 330101-00-20-10-10 | 3300 XL Proximity Probe (10mm) | 0 to 10mm | 4-20 mA | 0.5 kg |

| 330101-00-20-20-04 | 3300 XL Proximity Probe (5mm, Long Cable) | 0 to 10mm | 4-20 mA | 0.55 kg |

| 330102-00-20-20-02 | 3300 XL Proximity Probe (8mm, Industrial) | 0 to 10mm | 4-20 mA | 0.6 kg |

| 330105-00-20-20-01 | 3300 XL Proximity Probe (8mm, Heavy Duty) | 0 to 10mm | 4-20 mA | 0.7 kg |

Popular Bently Nevada Models

Here are six other popular models from Bently Nevada that are widely used in vibration and machinery condition monitoring:

| Model Number | Description | Measuring Range | Output Signal | Weight |

|---|---|---|---|---|

| 3500/32 | 3500 Series Vibration Monitor | 0 to 100mm | 4-20 mA | 2.0 kg |

| 330500-01-40-10-02 | 3300 XL Vibration Probe (High Sensitivity) | 0 to 5mm | 4-20 mA | 0.85 kg |

| 350400-00-20-10-03 | 3500 Series Vibration Sensor | 0 to 50mm | 4-20 mA | 1.5 kg |

| 330103-00-20-10-20 | 3300 XL Proximity Sensor (Heavy Duty) | 0 to 10mm | 4-20 mA | 1.1 kg |

| 330500-01-50-10-02 | 3300 XL Vibration Probe (Standard) | 0 to 10mm | 4-20 mA | 0.75 kg |

| 330400-00-20-10-01 | 3300 Series Proximity Probe | 0 to 12mm | 4-20 mA | 0.65 kg |

Excellent PLC

Excellent PLC