| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

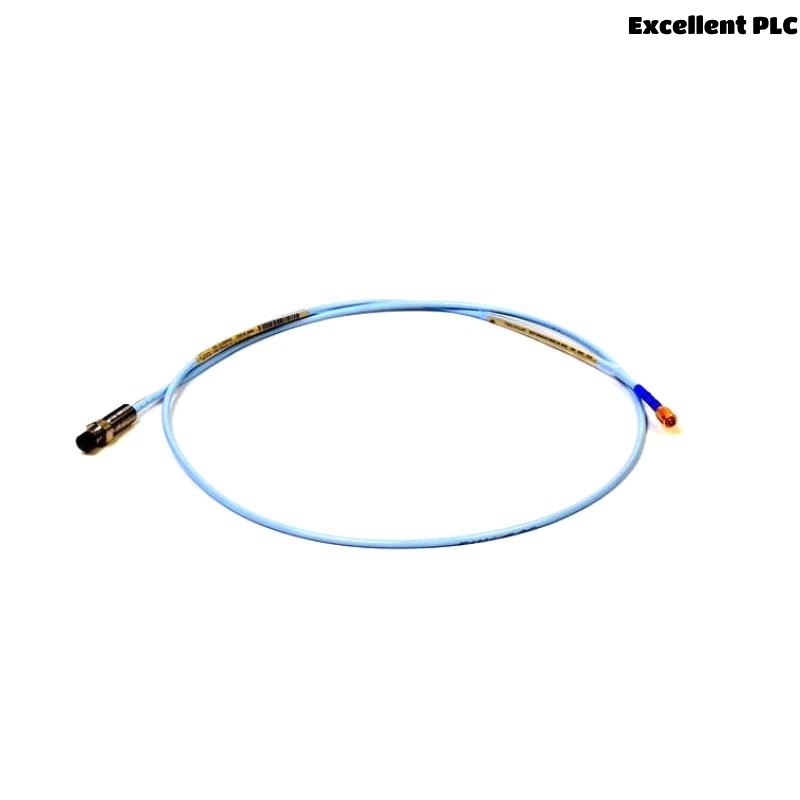

The Bently Nevada 330101-00-27-50-02-05 is a high-performance component in the 3300 XL 8 mm Proximity Transducer System, designed by GE’s Bently Nevada division. This proximity probe is specifically tailored for precise vibration and displacement measurements in industrial machinery. Known for its ruggedness, excellent linearity, and ease of installation, this product plays a critical role in condition monitoring systems, particularly for rotating equipment such as turbines, compressors, pumps, and motors.

With a proven legacy in the field of predictive maintenance and machinery protection, the 3300 XL series ensures long-term stability and accuracy in demanding environments. The specific model “330101-00-27-50-02-05” refers to a 3300 XL probe with a 27-inch cable length and a 50-ohm coaxial connector, commonly used in hazardous and high-vibration industrial settings.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330101-00-27-50-02-05 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy Current (non-contact) |

| Tip Diameter | 8 mm |

| Total Length | 5 meters |

| System Compatibility | Works with 3300 XL Proximitor Sensor and extension cables |

| Linear Range | 2 mm (80 mils) |

| Non-Linearity | Within ±0.25% of full-scale output over linear range |

| Probe Case Material | AISI 304 stainless steel |

| Cable Type | Armored coaxial cable |

| Connector Type | Miniature coaxial, 50-ohm, standard 3300 XL configuration |

| Operating Temperature | −35°C to +177°C (−31°F to +350°F) |

| Humidity Range | 0 to 95% non-condensing |

| Shock Survivability | Up to 10,000 g |

| Protection Rating | IP68 (with appropriate sealing) |

| Weight | 1.615 kg |

Product Applications

The 330101-00-27-50-02-05 proximity probe is widely used in rotating machinery monitoring systems across various industries, including:

-

Oil & Gas – turbines, pumps, and compressors in refineries

-

Power Generation – steam and gas turbines in power plants

-

Petrochemical – vibration monitoring of critical rotating units

-

Mining & Metals – motor shaft displacement detection

-

Marine – propulsion system condition monitoring

-

Aerospace Testing – non-contact vibration analysis for turbines

This probe is often deployed in combination with Proximitor sensors and extension cables for a complete eddy-current sensing solution.

Product Advantages

-

Field-Proven Reliability: Designed for harsh environments, including high vibration, extreme temperatures, and oil exposure.

-

Consistent Accuracy: Tight linearity specifications and stable performance over time.

-

Global Standard: Compatible with API 670 standards for machinery protection systems.

-

Ease of Installation: Flexible mounting options and standard connectors reduce setup time.

-

Integrated System Compatibility: Seamlessly integrates with Bently Nevada’s full range of Proximitor systems and monitoring modules.

-

Rugged Construction: Constructed with stainless steel and armored cabling for maximum durability.

-

Extended Lifetime: Long service intervals and minimal maintenance reduce operational costs.

-

Custom Length Options: Available in various lengths to suit different machine layouts.

Frequently Asked Questions (FAQ)

-

What does the part number 330101-00-27-50-02-05 specify?

It specifies a 3300 XL 8 mm proximity probe with a 27-inch probe length, 50-inch cable, and standard connector type. -

Is this probe compatible with all Bently Nevada monitors?

It is compatible with Bently Nevada’s 3300 XL Proximitor Sensor and other related systems. -

What type of signal does this probe output?

The probe outputs a voltage proportional to the distance between the probe tip and the target surface. -

Can the probe be used in hazardous environments?

Yes, it is built to withstand harsh industrial conditions, including explosive zones with proper installation. -

How accurate is this probe?

It has a non-linearity of ±0.25% over the linear range, providing highly accurate displacement readings. -

Is the cable length customizable?

Yes, Bently Nevada offers various lengths for probes and cables to suit different installation needs. -

How should the probe be mounted?

It is typically mounted with a threaded sleeve or bracket, depending on machine geometry and access. -

Does it require regular maintenance?

Minimal maintenance is required. However, periodic inspection during shutdowns is recommended. -

What is the lifespan of the 3300 XL proximity probe?

With proper installation and use, the probe can last several years without degradation. -

What industries commonly use this probe?

Industries include oil & gas, power generation, mining, chemical processing, and marine engineering.

Recommended Related Models (Same Series)

| Model Number | Probe Length | Cable Length | Connector Type | Tip Diameter |

|---|---|---|---|---|

| 330101-00-20-10-02-05 | 20 in | 10 in | 50-ohm | 8 mm |

| 330101-00-12-10-02-05 | 12 in | 10 in | 50-ohm | 8 mm |

| 330101-00-05-10-02-05 | 5 in | 10 in | 50-ohm | 8 mm |

| 330101-00-15-05-02-00 | 15 in | 5 in | 75-ohm | 8 mm |

| 330104-00-12-10-02-05 | 12 in | 10 in | 50-ohm | 5 mm (mini) |

| 330103-00-07-05-02-00 | 7 in | 5 in | 75-ohm | 11 mm |

Popular Models from Bently Nevada (Same Brand)

| Model Number | Product Type | Description | Typical Use |

|---|---|---|---|

| 3300 XL 5 mm | Proximity Probe | Smaller tip for compact installations | Small rotating machinery |

| 330104-00-12-10-02 | Proximity Probe | Mini 5 mm tip probe | Space-constrained areas |

| 3500/42M | Vibration Monitoring Module | Dual-channel dynamic vibration monitor | API 670 machinery protection |

| 3500/22M | Transient Data Interface | Communication module for 3500 systems | System interface integration |

| 330400 | Accelerometer | High-sensitivity sensor for vibration measurement | Bearings and gearboxes |

| 990-04-XX-01-XX | Keyphasor Module | Shaft phase reference module | Rotating machinery analysis |

Excellent PLC

Excellent PLC