| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

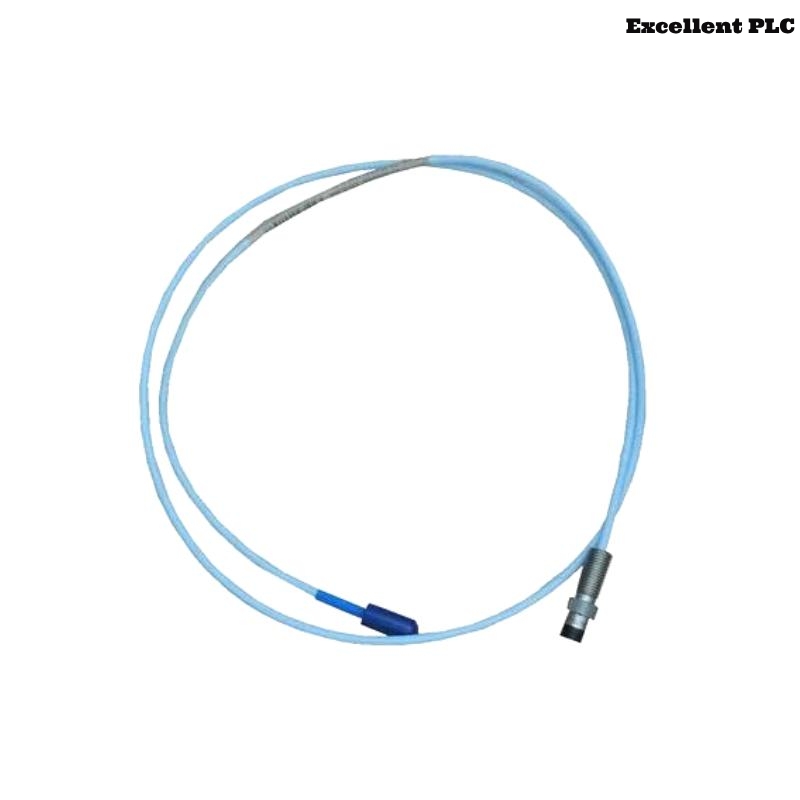

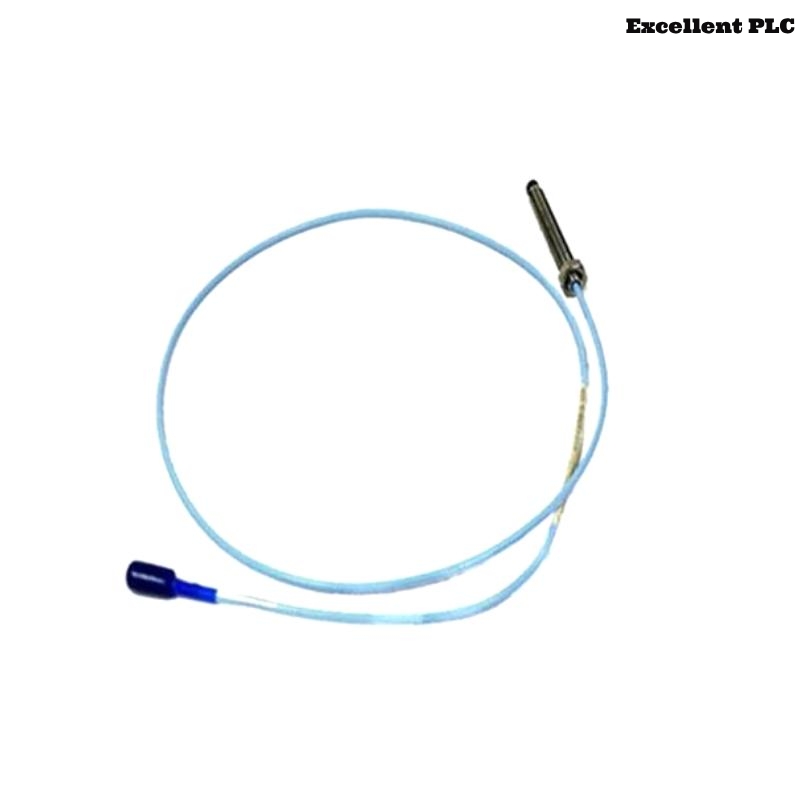

The Bently Nevada 330101-00-28-10-02-05 is part of the 3300 XL 8mm Proximity Transducer System, one of the most reliable and widely used solutions in the industry for machinery condition monitoring and protection. Manufactured by Bently Nevada, a brand under Baker Hughes, this probe is designed to deliver accurate and stable non-contact measurements of shaft position and vibration in rotating machinery.

This model features an 8 mm probe tip and a 28-inch integral cable with a straight connector, making it ideal for medium-length installations. The 330101-00-28-10-02-05 is engineered for robust performance, compliant with API 670 standards, and is optimized for use in harsh industrial environments such as power generation, oil & gas, and process automation.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | 3300 XL 8mm Proximity Probe |

| Part Number | 330101-00-28-10-02-05 |

| Probe Tip Diameter | 8 mm |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Probe Cable Length | 28 inches (711.2 mm) |

| Cable Type | Coaxial, integral |

| Connector Type | Miniature coaxial, straight boot |

| Thread Type | 3/8-24 UNF-2A |

| Total Length | 1.0 meter |

| Sensing Range | 0.25 mm to 2.0 mm (10 to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) ±5% |

| Linear Range | ±0.127 mm (±5 mils) |

| Target Material | Calibrated for 4140 steel |

| Operating Temperature Range | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Shock Limit | 5000 g peak |

| Vibration Limit | 50 g, 10–2000 Hz |

| Enclosure Material | Stainless Steel |

| Environmental Sealing | Epoxy-filled tip, moisture-resistant |

| Certifications | CE, RoHS, API 670 compliant |

| Compatible Systems | 3300 XL Extension Cable + Proximitor® Sensor |

| Weight | 0.323 kg |

Product Applications

The 330101-00-28-10-02-05 is suitable for a wide range of industrial applications involving rotating machinery. Typical applications include:

-

Steam and Gas Turbines: Monitoring radial and axial shaft position.

-

Compressors: Measuring shaft vibration and movement to prevent surge or misalignment.

-

Electric Motors and Generators: Real-time vibration monitoring for predictive maintenance.

-

Pumps and Industrial Fans: Non-contact vibration analysis for early fault detection.

-

Gearboxes and Couplings: Detecting misalignment and gear wear through vibration signature.

-

Critical Process Machinery: For machinery in refineries, petrochemical, and paper industries.

Product Advantages

-

Proven Field Reliability: Operates reliably in thousands of machinery installations globally.

-

API 670 Compliance: Meets the stringent requirements for proximity transducer systems in critical machinery.

-

Precision Measurement: Delivers consistent, accurate readings across a wide temperature and pressure range.

-

Versatile Configuration: Available in multiple cable lengths and thread types for flexible system design.

-

Environment-Ready: Withstands harsh conditions such as high temperatures, shock, vibration, oil, and dust.

-

Stable Calibration: Factory calibrated to ensure measurement stability over time.

-

Long Service Life: Durable materials and sealed construction extend operating life and reduce maintenance.

-

System Compatibility: Fully compatible with Bently Nevada’s 3300 XL series Proximitor® sensors and extension cables.

-

Rapid Response: Immediate feedback of vibration and displacement changes critical to machine protection.

Frequently Asked Questions (FAQ)

-

Is this probe compatible with the 3300 XL Proximitor Sensor?

→ Yes, it is specifically designed to be used with the 3300 XL Proximitor Sensor and matching extension cables. -

Can the cable length be modified in the field?

→ No, the cable length is factory-set and matched to the Proximitor sensor. Field modification will compromise system accuracy. -

What is the expected output voltage at the mid-gap position?

→ The mid-gap voltage is typically around -10 VDC, depending on installation and calibration. -

What kind of shaft material is best for calibration?

→ 4140 steel is the standard material used during calibration. Deviations may require recalibration. -

Is it suitable for hazardous area installations?

→ Yes, with the appropriate intrinsic safety barriers and certified installation practices. -

How do I test if the probe is still functioning properly?

→ Use a Bently signal checker or diagnostic software in combination with a dial micrometer for accuracy verification. -

Can this be used for axial thrust monitoring?

→ Yes, when correctly installed and configured with a matching proximitor module. -

What is the probe’s lifespan under continuous use?

→ Probes typically last for years under normal operation. However, extreme environments may reduce service life. -

Does this probe support condition monitoring and protection systems?

→ Absolutely. It integrates seamlessly into Bently Nevada’s 3500 series monitoring systems. -

What happens if I exceed the vibration/shock limit?

→ Exceeding limits can permanently damage the probe or degrade its accuracy. Always install according to specifications.

Related Models from the Same Series or Closely Matched

| Model Number | Description | Cable Length | Thread Size |

|---|---|---|---|

| 330101-00-24-10-02-05 | 8mm Probe, 24” cable, straight connector | 24 inches | 3/8-24 UNF |

| 330101-00-32-10-02-05 | 8mm Probe, 32” cable, straight connector | 32 inches | 3/8-24 UNF |

| 330101-00-36-10-02-05 | 8mm Probe, 36” cable, straight connector | 36 inches | 3/8-24 UNF |

| 330101-00-20-10-02-05 | 8mm Probe, 20” cable, straight connector | 20 inches | 3/8-24 UNF |

| 330105-02-12-10-02-00 | 11mm Probe, heavy-duty industrial environments | 12 inches | M10 x 1 |

| 330103-00-08-10-02-00 | Compact 5mm Probe for limited space applications | 8 inches | 1/4-28 UNF |

Popular Models from Bently Nevada (Same Brand)

| Model Number | Description | Application Area | Feature |

|---|---|---|---|

| 3300 XL 11mm (330105) | Larger tip for longer range displacement | Turbines, Compressors | High mechanical durability |

| 330400/330425 | Piezoelectric Velomitor sensor | General vibration monitoring | Velocity-based sensing |

| 3500/42M | Dynamic Vibration Monitoring Module | Machinery protection systems | Real-time monitoring |

| 3500/22M | Transient Data Interface Module | Data acquisition | High-speed diagnostics |

| 3701/40 | Wireless Vibration Monitor | Remote assets | Wireless data transmission |

| 190501 | Accelerometer for casing vibration | Pumps, Motors, Gearboxes | Industrial-grade vibration sensor |

Excellent PLC

Excellent PLC