| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

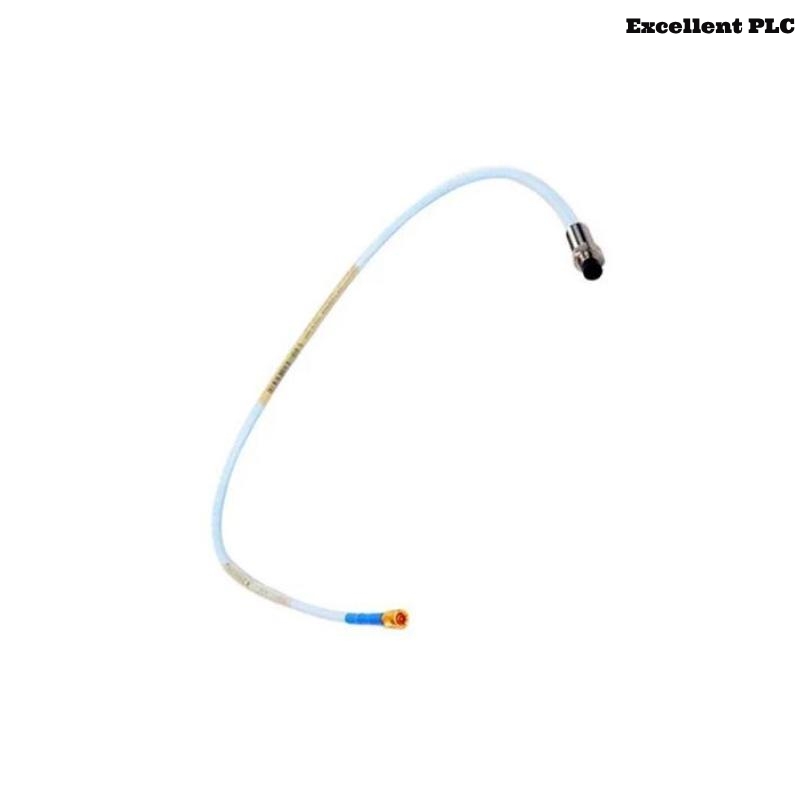

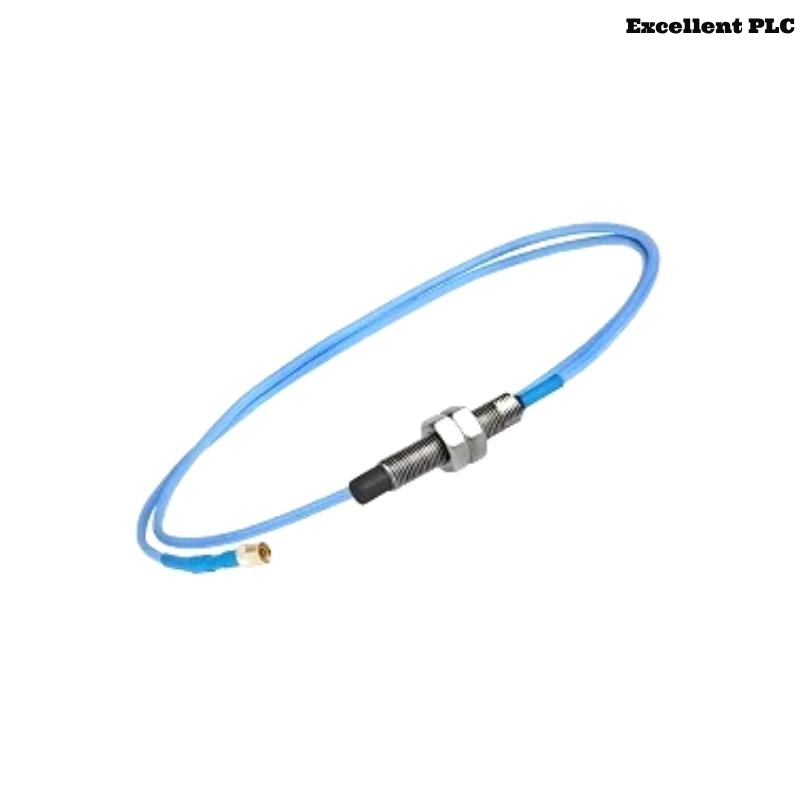

The Bently Nevada 330101-00-30-10-02-00, part of the 3300 XL 8mm Proximity Probe System, is an industry-standard, non-contact sensor designed to measure vibration and shaft position in rotating machinery. Known for its rugged design, high precision, and reliability, this probe is widely utilized in predictive maintenance and condition monitoring systems. The probe is part of a system that includes the proximity probe, extension cable, and a Proximitor sensor, all tuned to work together to offer consistent and accurate performance across a broad range of industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330101-00-30-10-02-00 |

| Series | 3300 XL |

| Sensing Principle | Eddy current (non-contact) |

| Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A |

| Case Material | AISI 303 Stainless Steel |

| Cable Length | 1 meter |

| Connector Type | Miniature coaxial connector with armor (option code 10) |

| Target Material | Best performance on AISI 4140 steel |

| Linear Range | 2 mm (80 mils) |

| Non-Linearity | ±0.025 mm (±1 mil) or 1% of full scale |

| Working Temperature | −35°C to +177°C (−31°F to +350°F) |

| Insulation Resistance | >10 MΩ at 500 VDC |

| Protection Rating | IP67 (with proper sealing) |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 3300 XL 8mm proximity probe system is designed for use in a wide range of critical rotating machinery such as:

-

Steam turbines

-

Gas turbines

-

Compressors

-

Motors

-

Generators

-

Gearboxes

-

Centrifugal pumps

Typical industries that use this product include:

-

Power generation

-

Oil & gas

-

Petrochemical

-

Water treatment

-

Steel and mining

-

Pulp and paper

These probes are primarily used for:

-

Shaft vibration monitoring

-

Radial and axial displacement measurements

-

Thrust position monitoring

-

Condition-based maintenance (CBM) systems

Product Advantages

-

Robust Construction: The 330101-00-30-10-02-00 probe features a stainless steel casing and is built for harsh environments, ensuring long operational life.

-

High Precision: Offers extremely accurate and repeatable measurements, critical for high-speed machinery.

-

Interchangeable Components: Compatible with 3300 XL Proximitor sensors and extension cables, providing flexibility in system design.

-

Easy Installation: The probe features a threaded body with locknuts for secure and simple mounting.

-

Sealed Connector: Rugged connector system with optional cable armor ensures protection against physical damage and environmental ingress.

-

Global Standard Compliance: Recognized by major machinery manufacturers and used worldwide for critical condition monitoring tasks.

-

Wide Operating Temperature: Capable of operating in elevated temperature environments commonly found in turbine enclosures.

Frequently Asked Questions (FAQ)

-

What is the main function of the 330101-00-30-10-02-00 probe?

It is used to measure the dynamic and static displacement of machine shafts using non-contact eddy current technology. -

Is the probe compatible with older Bently Nevada systems?

Yes, it is backward-compatible with many 7200 and 3300 systems when properly configured. -

Can it be used in high-temperature environments?

Yes, it supports operations up to 177°C (350°F). -

What is the maximum distance the probe can be mounted from the shaft?

The linear measurement range is 2 mm (80 mils), and typical standoff is around 1.0 mm. -

What type of material does the probe best work with?

AISI 4140 steel is the standard target material for accurate readings. -

Can this probe be used underwater or in wet environments?

Yes, the IP67 rating allows use in wet and dusty conditions when properly installed and sealed. -

What kind of cabling does it use?

It uses a coaxial cable with optional armor for added protection in industrial environments. -

How does it connect to the monitoring system?

It connects to a Proximitor sensor, which then outputs the processed signal to the monitoring or control system. -

What maintenance is required for the probe?

It is maintenance-free under normal operation but should be inspected periodically for physical damage or cable wear. -

Is this probe suitable for safety-critical systems like turbine shutdown?

Yes, it is often used in safety-critical applications where real-time shaft position monitoring is essential.

Related Models (Same Series or Function)

| Model Number | Cable Length | Probe Tip | Connector Type | Application Notes |

|---|---|---|---|---|

| 330101-00-05-10-02-00 | 5 feet | 8 mm | Mini coaxial | For compact installations |

| 330101-00-10-10-02-00 | 10 feet | 8 mm | Mini coaxial | Mid-range cable option |

| 330101-00-15-10-02-00 | 15 feet | 8 mm | Mini coaxial | Standard motor & pump setups |

| 330101-00-20-10-02-00 | 20 feet | 8 mm | Mini coaxial | Used in small turbine packages |

| 330103-00-10-10-02-00 | 10 feet | 5 mm | Mini coaxial | Suitable for small shaft diameters |

| 330104-00-10-10-02-00 | 10 feet | 11 mm | Mini coaxial | For large displacement machinery |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Type | Application | Notes |

|---|---|---|---|

| 3500/22M | Transient Data Interface | Real-time data collection | High-speed data interface for 3500 series |

| 3300 XL 5mm | Proximity Probe System | Small shaft monitoring | Shorter tip for limited space |

| 330103-00-05-10-02-00 | Proximity Probe (5mm) | Compact machinery | High precision for small-scale setups |

| 330104-00-05-10-02-00 | Proximity Probe (11mm) | Heavy-duty equipment | For large shaft displacements |

| 3500/42M | Proximitor Monitor | Vibration + Position monitoring | Rack-based module for 3500 systems |

| 330400 | Velocity Transducer | General-purpose vibration monitoring | Uses piezoelectric sensing |

Excellent PLC

Excellent PLC