| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

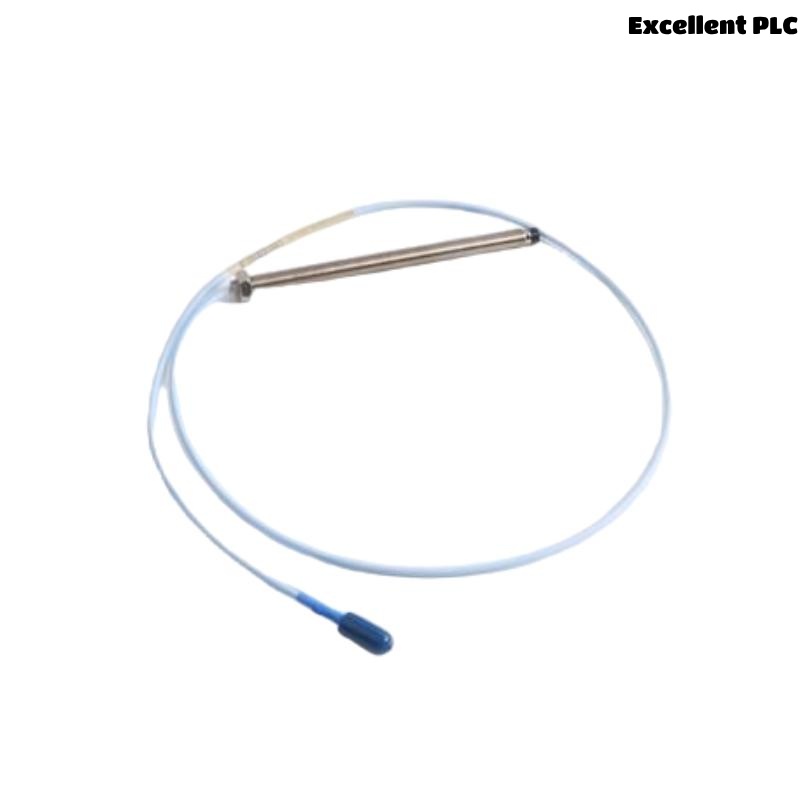

The Bently Nevada 330101-00-40-10-01-00 is part of the 3300 XL 8mm Proximity Transducer System, one of the most reliable and widely used vibration monitoring solutions in rotating machinery. Designed and manufactured by Bently Nevada (a Baker Hughes business), this proximity probe offers precise, non-contact measurement of shaft position and vibration in critical machinery such as turbines, compressors, motors, and pumps.

Built to withstand harsh industrial conditions, the 3300 XL 8mm series provides superior stability, robust construction, and long-term reliability. The specific model 330101-00-40-10-01-00 features a 1 meter total length and a matching proximitor sensor, enabling full system compatibility and optimal performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-40-10-01-00 |

| Series | Bently Nevada 3300 XL 8mm |

| Probe Tip Diameter | 8 mm |

| Sensing Range | Up to 2 mm (80 mils), linear over 200 mils |

| Total Length | 1 meter |

| Connector Type | ClickLoc™ Keyphasor-style connectors |

| Material (Probe Housing) | AISI 304 Stainless Steel |

| Thread Type | 1/4-28 UNF or M8x1, depending on configuration |

| Mounting | Threaded (direct mount or via bracket) |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C |

| Frequency Response | 0 to 10 kHz |

| Output | Voltage proportional to gap |

| Target Material | Ferromagnetic (typically 4140 steel) |

| Environmental Rating | IP68 / NEMA 6P |

| Compliance | CE, RoHS, ATEX (with selected configurations) |

| Weight | 0.323 kg |

Product Applications

The 330101-00-40-10-01-00 proximity probe is used in a variety of high-precision, mission-critical industrial applications:

-

Steam and Gas Turbines

Shaft vibration and position monitoring to avoid rotor-stator contact. -

Compressors

Radial and axial vibration detection for early fault diagnosis. -

Electric Motors and Generators

Shaft displacement measurement to ensure alignment and health. -

Pumps and Gearboxes

Vibration trending to detect bearing wear and imbalance. -

Centrifuges and Fans

Dynamic behavior analysis to minimize unplanned downtime. -

Petrochemical and Refining Plants

Integration into condition monitoring and machinery protection systems (MPS).

Product Advantages

-

Field-Proven Reliability

The 3300 XL 8mm series is industry-trusted for over two decades in demanding conditions. -

Complete System Compatibility

Fully compatible with Bently Nevada Proximitor® sensors and extension cables. -

High Accuracy and Repeatability

Provides precise shaft position and vibration readings under extreme conditions. -

Robust Mechanical Design

Stainless steel construction and IP68 rating ensure durability even in submerged or hazardous environments. -

Ease of Installation and Maintenance

Color-coded, keyed connectors (ClickLoc™) reduce wiring errors and downtime. -

Extended Operating Temperature Range

Designed for harsh industrial temperatures, suitable for turbine casings and other high-heat environments.

Frequently Asked Questions (FAQ)

-

What happens if the probe is exposed to oil, water, or dust?

The probe is IP68-rated, which means it can withstand full immersion in oil or water under pressure. Just ensure the connector is properly sealed, and avoid physical damage to the probe tip. -

Can this probe be used with other proximitor modules?

Yes, it’s fully compatible with Bently Nevada 3300 XL Proximitor® sensors. -

Is it suitable for submerged applications?

Yes, it’s IP68-rated and can function reliably in submerged or humid environments. -

Does this probe support Keyphasor® applications?

While primarily for vibration, some configurations can be adapted for phase/reference measurements. -

What is the recommended mounting style?

Direct threaded mounting into the machine housing or bracket-mounted for ease of access. -

What material should the target be made of?

Typically, ferromagnetic materials like 4140 steel offer the most accurate results. -

Can I use this probe in hazardous areas?

Yes, certain configurations carry ATEX or CSA certifications for hazardous zones. -

Does the cable length affect signal accuracy?

The system is calibrated based on total cable length (probe + extension); correct pairing ensures accuracy. -

What software is used with this probe?

Bently Nevada’s System 1® and related monitoring platforms support this sensor for real-time data acquisition. -

How often does the probe need replacement?

Under normal use, the probe can last many years. Replace if physically damaged or exposed to extreme wear.

Related Models – Same Series (3300 XL 8mm)

| Model Number | Description | Key Difference |

|---|---|---|

| 330101-00-20-10-01-00 | Probe with 20” cable, 10’ extension | Shorter probe cable |

| 330101-00-60-10-01-00 | Probe with 60” cable | Extended probe cable |

| 330101-00-40-05-01-00 | Probe with 5’ extension cable | Shorter system length |

| 330103-00-40-10-01-00 | 3300 XL 5mm Probe | 5 mm tip size instead of 8 mm |

| 330105-02-12-10-02-00 | High-temperature probe version | For use in elevated temperature zones |

| 330106-05-30-10-02-00 | Heavy-duty probe with armor | Extra protection in abrasive environments |

Popular Bently Nevada Models

| Model Number | Product Type | Application |

|---|---|---|

| 330103-00-10-10-02-00 | 3300 XL 5mm Proximity Probe | Compact machinery or space-limited locations |

| 330104-00-05-10-02-00 | 3300 XL Reverse Mount Probe | Special orientation mounting requirements |

| 330180-91-05 | Velomitor Piezo Velocity Sensor | Case vibration monitoring |

| 3500/22M | Transient Data Interface Module | Captures transient dynamic signals |

| 3500/42M | Proximitor Monitor Module | Processes signals from proximity transducers |

| 3701/55 | TSI (Turbine Supervisory Instrumentation) | Critical turbine condition monitoring |

Excellent PLC

Excellent PLC