| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

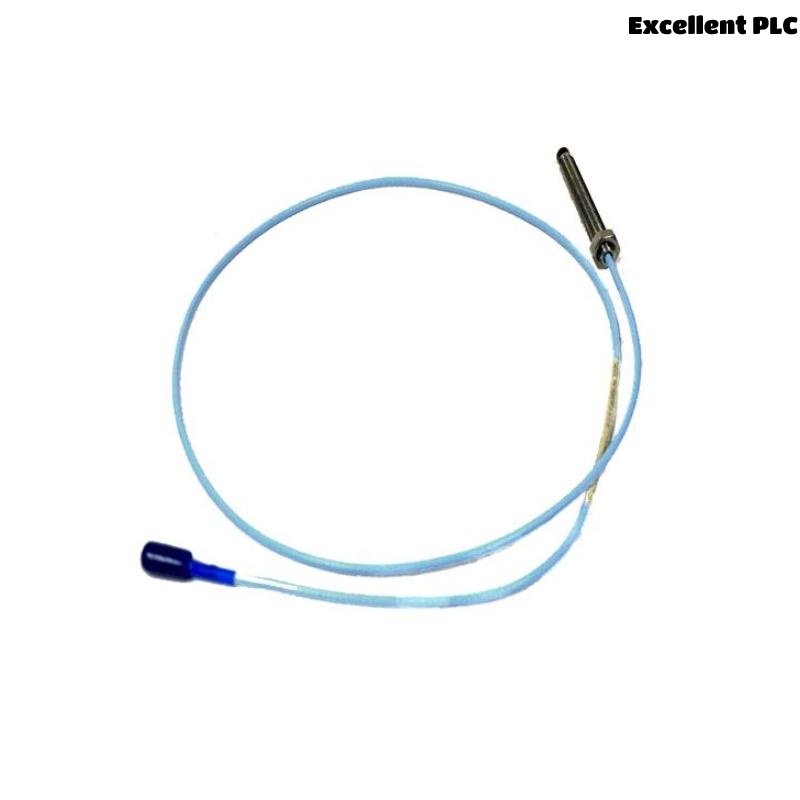

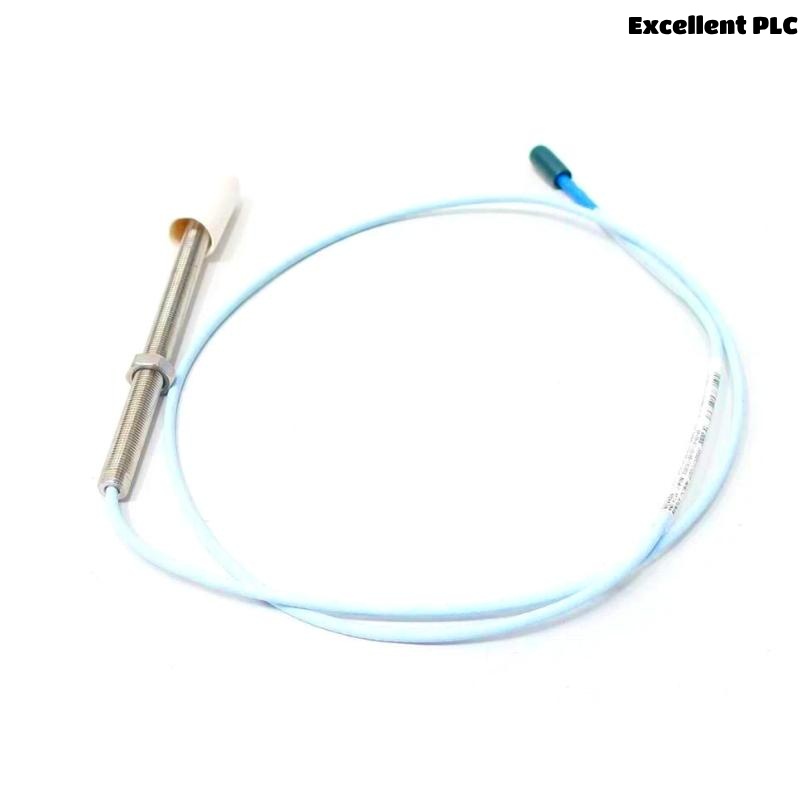

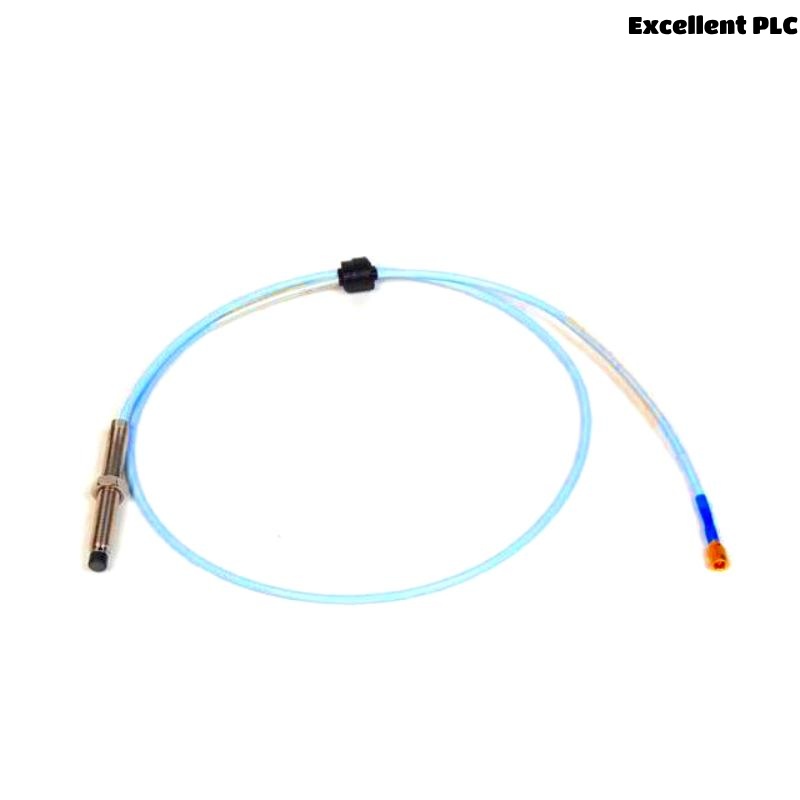

The Bently Nevada 330101-00-48-10-02-RU is a high-precision proximity probe from the 3300 XL 8 mm series, designed for dynamic vibration and static position measurements. It forms a part of a complete transducer system that includes the proximity probe, extension cable, and Proximitor sensor. This model is particularly suited for fluid-film bearing machines, ensuring reliable performance in harsh industrial environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Series | 3300 XL 8 mm Proximity Probe |

| Model Number | 330101-00-48-10-02-RU |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Case Material | Stainless Steel (AISI 303/304) |

| Cable Type | 75Ω triaxial, FEP insulated |

| Connector Type | Miniature coaxial ClickLoc connector |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Operating Temperature | –52°C to +177°C |

| Pressure Sealing | Viton® O-ring seal |

| Mounting Thread | 3/8-24 UNF |

| Recommended Gap | 1.27 mm (50 mils) |

| Linear Range | 0.25 mm to 2.3 mm |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Compliance | API 670 compliant, CE, ATEX, CSA, IECEx, RoHS |

Applications

-

Shaft vibration monitoring

-

Thrust position measurements

-

Keyphasor reference signals

-

Overspeed and speed measurements

-

Condition monitoring in turbines, compressors, and large rotating equipment

Advantages

-

Full compliance with API 670

-

Interchangeable probe, extension cable, and Proximitor sensor

-

High immunity to EMI/RFI

-

Finger-tight, corrosion-resistant ClickLoc connectors

-

Robust mechanical construction with TipLoc and CableLoc design

-

Suitable for high-temperature environments (up to 177°C standard)

Frequently Asked Questions (FAQ)

Q1: What is the linear measurement range of this probe?

A1: It measures from 0.25 mm to 2.3 mm with high accuracy.

Q2: Can this probe be used in high-temperature environments?

A2: Yes, the standard version supports up to +177°C. ETR versions can go up to +218°C.

Q3: Is it compatible with older 3300 systems?

A3: Yes, it is backward compatible with non-XL 3300 5 mm and 8 mm systems.

Q4: What type of connector is used?

A4: It uses a ClickLoc miniature coaxial connector with optional protector.

Q5: Is field calibration required?

A5: No, factory calibration to AISI 4140 steel allows component interchange without field calibration.

Q6: What shaft sizes are recommended for use?

A6: Minimum shaft diameter is 50.8 mm; 76.2 mm is recommended to minimize cross-talk.

Q7: What material is the probe case made of?

A7: It is made of corrosion-resistant stainless steel (AISI 303/304).

Q8: What’s the output sensitivity?

A8: It provides 7.87 V/mm (200 mV/mil) ±5% for 1 m systems.

Q9: Is it suitable for hazardous areas?

A9: Yes, it meets CSA, ATEX, IECEx certifications for use in hazardous locations.

Q10: What is the bend radius of the cable?

A10: Minimum bend radius is 25.4 mm (1.0 inch).

Related Models in the Same Series

| Model Number | Thread Type | Length | Armor | FluidLoc | Weight |

|---|---|---|---|---|---|

| 330101-00-08-10-02-00 | 3/8-24 UNF | 1.0 m | No | No | 0.323 kg |

| 330101-00-20-10-02-00 | 3/8-24 UNF | 2.0 m | No | No | 0.340 kg |

| 330102-00-20-10-02-00 | 3/8-24 UNF | 2.0 m | Yes | No | 0.450 kg |

| 330103-00-10-10-02-00 | M10x1 | 1.0 m | No | No | 0.323 kg |

| 330104-00-10-10-02-00 | M10x1 | 1.0 m | Yes | No | 0.450 kg |

| 330105-02-12-10-02-00 | 3/8-24 UNF | 1.0 m | No | No | 0.323 kg |

Popular Bently Nevada Models

| Model Number | Product Type | Application | Length | Weight |

|---|---|---|---|---|

| 330104-00-06-10-02-00 | 8 mm Probe, M10x1 Thread | Radial/Thrust Positioning | 0.6 m | 0.320 kg |

| 330130-040-02-00 | Extension Cable | Signal Extension | 4.0 m | 0.140 kg |

| 330180-10-05 | Proximitor Sensor | Panel Mount, 1.0 m System | – | 0.246 kg |

| 3500/42M-01-00 | Vibration Monitor | Proximitor Seismic Monitoring | – | 0.540 kg |

| 3500/22M-01-01-00 | Transient Data Interface | System Configuration & Communication | – | 0.610 kg |

| 330500-02-00 | Velocity Transducer | Low-Frequency Vibration Monitoring | – | 0.500 kg |

Excellent PLC

Excellent PLC