| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

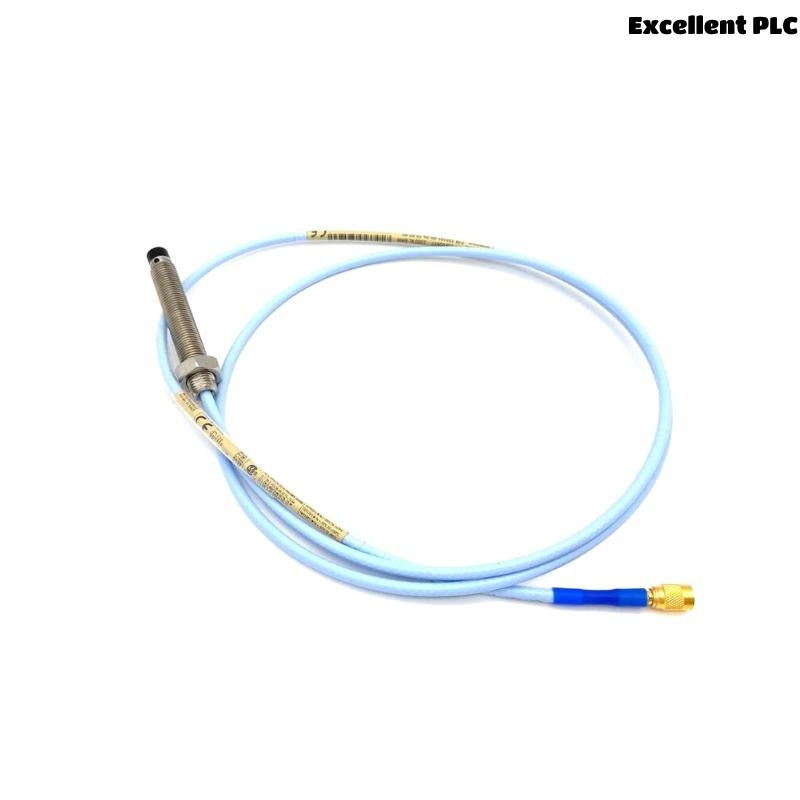

The Bently Nevada 330101-00-50-20-02-CN 3300 XL 8mm Proximity Probe is an advanced non-contact sensor designed to precisely measure shaft vibration and relative position in a wide range of rotating machinery. This model belongs to the trusted 3300 XL 8mm series and features a 2 meters total length armored extension cable, making it ideal for long-reach or high-demand industrial installations.

Backed by Bently Nevada’s industry-leading expertise in condition monitoring and machinery protection, this probe ensures superior measurement accuracy even in the harshest operating environments. It is compatible with Bently Nevada’s 3500 monitoring systems and is widely used across industries such as oil & gas, petrochemical, power generation, and heavy manufacturing.

The 330101-00-50-20-02-CN model is highly reliable, offering excellent resistance to high temperatures, mechanical vibration, and electrical interference, enabling early detection of equipment degradation and supporting proactive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-50-20-02-CN |

| Product Series | 3300 XL 8mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Probe Tip Material | PPS (Glass-reinforced Polyphenylene Sulfide) |

| Probe Thread Size | 3/8-24 UNF |

| Total Length | 2 meters |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Measurement Range | 80 mils (2.0 mm) |

| Output Voltage Range | -24 VDC to +24 VDC |

| Linearity | ±0.25% of full-scale |

| Frequency Response | 0 Hz to 10 kHz (-3 dB) |

| Operating Temperature Range | -51 °C to +177 °C (-60 °F to +350 °F) |

| Maximum Vibration Limit | 50 g peak |

| Maximum Shock Limit | 5000 g peak |

| Environmental Protection Rating | IP68 |

| Electrical Interference Immunity | High EMI / RFI immunity |

| Housing Material | Stainless Steel |

| Certifications | CE, ATEX, CSA, RoHS Compliant |

| Weight | 0.646 kg |

Applications

The 330101-00-50-20-02-CN Proximity Probe is extensively used in critical machinery applications where reliable shaft vibration and displacement monitoring are essential for safe and efficient operations:

-

Steam and Gas Turbines

Real-time vibration and position monitoring for primary turbines. -

Compressors

Accurate detection of radial and axial shaft movements. -

Electric Motors & Generators

Continuous monitoring of imbalance, shaft misalignment, and bearing wear. -

Pumps & Blowers

Early warning of cavitation, bearing degradation, or impeller imbalance. -

Gearboxes

Monitoring shaft displacement and vibration for optimal gearbox health. -

Heavy Industrial Applications

Power plants, refineries, petrochemical complexes, marine propulsion systems, and pulp & paper plants.

Advantages

-

Extended Reach for Challenging Installations

With a 2 meters probe length armored extension cable, it provides flexibility for installations with deep or insulated housings. -

Exceptional Measurement Precision

±0.25% linearity ensures repeatable and accurate measurements critical for early fault detection. -

Rugged Industrial Design

Stainless steel body and PPS tip withstand harsh environmental conditions. -

Broad Operating Temperature Range

Capable of high-performance operation from -51 °C to +177 °C. -

Excellent Vibration and Shock Resistance

Designed for up to 50 g vibration and 5000 g shock—ideal for heavy machinery. -

Superior IP68 Environmental Sealing

Guarantees protection against water and dust ingress for long service life. -

EMI / RFI Shielding

Maintains measurement accuracy in electrically noisy environments. -

Proven System Compatibility

Fully compatible with Bently Nevada 3500 Series and other condition monitoring systems. -

Reduced Downtime

Supports predictive maintenance strategies, minimizing unplanned outages. -

Global Certifications

Suitable for deployment in a wide range of international markets and hazardous zones.

FAQ

1. What is the main use of this probe?

It is used for non-contact measurement of shaft vibration and position to support condition monitoring and protect rotating machinery.

2. How long is the probe body?

The probe body is 50 inches (1270 mm) in length.

3. What is the total length for this model?

It includes a 2 meters armored extension cable.

4. Is it compatible with Bently Nevada 3500 Series?

Yes, it integrates seamlessly with the 3500 Series and other compatible Bently Nevada monitoring systems.

5. What sensitivity does this probe offer?

The probe provides a sensitivity of 200 mV/mil (7.87 mV/μm).

6. Can it operate in environments with high temperatures?

Yes, it operates between -51 °C and +177 °C.

7. Is it suitable for harsh environments?

Absolutely—it features IP68 protection and is shock/vibration resistant.

8. In which industries is this product commonly used?

Industries include oil & gas, power generation, petrochemical, pulp & paper, marine, and manufacturing.

9. What is the maximum shock resistance of this probe?

It is rated to handle up to 5000 g peak shock.

10. Is this model certified for hazardous environments?

Yes, it meets CE, ATEX, CSA, and RoHS requirements for global deployment.

Related Models (Same Series / Similar)

| Model Number | Description |

|---|---|

| 330101-00-12-10-02-05 | 3300 XL 8mm Probe, 12-inch length |

| 330101-00-25-10-02-05 | 3300 XL 8mm Probe, 25-inch length |

| 330101-00-34-10-02-05 | 3300 XL 8mm Probe, 34-inch length |

| 330101-00-36-05-02-05 | 3300 XL 8mm Probe, 36-inch length |

| 330101-00-50-10-02-05 | 3300 XL 8mm Probe, 50-inch length, 10 ft cable |

| 330130-040-00 | 3300 XL Extension Cable, 4 meters |

Popular Bently Nevada Products (Same Brand)

| Model Number | Description |

|---|---|

| 3500/42M | Proximitor/Seismic Monitor |

| 3500/22M | Transient Data Interface Module |

| 3500/20 | Rack Interface Module |

| 3500/25 | Keyphasor Module |

| 1900/65A | Compact Machinery Protection System |

| 3300/16 | Proximitor Sensor |

Excellent PLC

Excellent PLC