| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Description

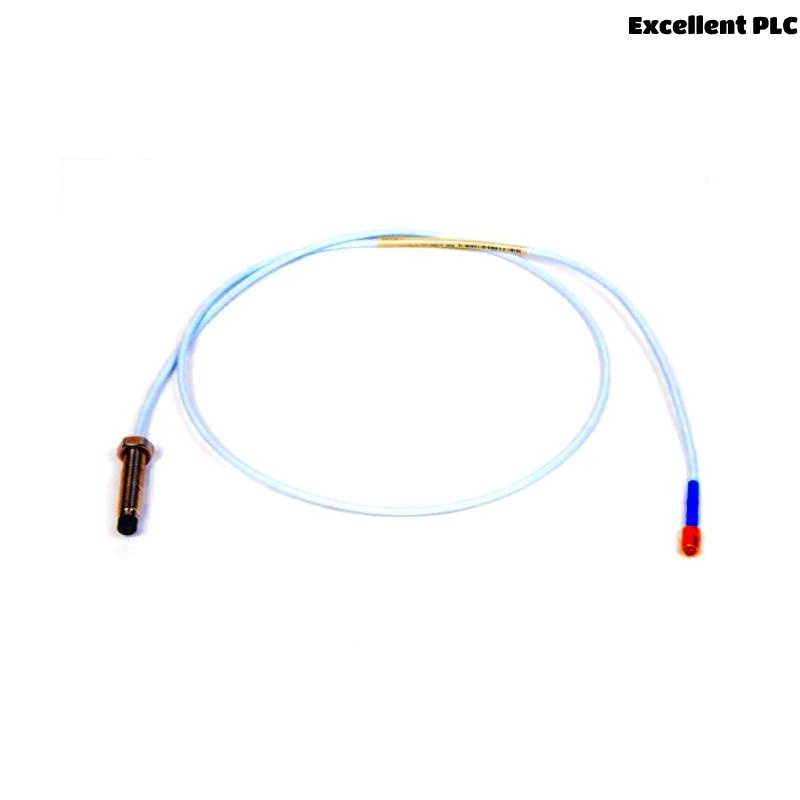

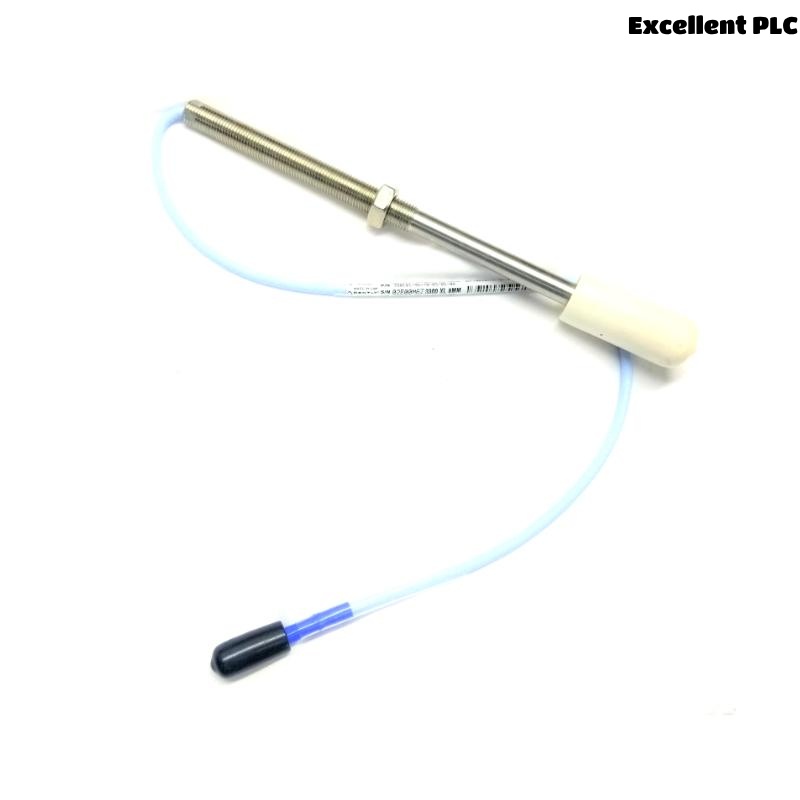

The 3300 XL 8 mm Proximity Probe is part of Bently Nevada’s advanced eddy current transducer system. It is used with an extension cable and a Proximitor Sensor to deliver highly accurate measurements of static (position) and dynamic (vibration) displacement. This specific model supports a total system length of 1 meter and includes a robust, gold-plated ClickLoc connector for reliable connections in demanding environments.

Technical Specifications

| Parameter | Value |

|---|---|

| System Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Tip Diameter | 8.0 mm |

| Probe Material | AISI 303/304 Stainless Steel |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Cable Type | 75 Ω Triaxial, FEP Insulated |

| Operating Temp (Standard Probe) | -52°C to +177°C |

| Operating Temp (ETR Probe) | -52°C to +218°C (tip), +260°C (cable) |

| Linear Range | 0.25 mm to 2.3 mm (10 to 90 mils) |

| Output Voltage | 200 mV/mil (7.87 V/mm) |

| Minimum Shaft Diameter | 50.8 mm (2 in), Recommended: ≥76.2 mm |

| Pressure Sealing | Viton O-ring |

| Environmental Protection | IP54+ (with connector protectors) |

| Connector Type | Miniature coaxial ClickLoc |

Applications

-

Turbomachinery: Accurate shaft vibration and position monitoring.

-

Electric Motors & Generators: Bearing and axial position tracking.

-

Compressors & Pumps: Ensures operational stability through vibration feedback.

-

Keyphasor Systems: Used as reference signal for phase and speed.

-

Overspeed Protection: Part of rotor dynamic protection systems.

Advantages

-

API 670 Compliant: Meets industry standards for vibration monitoring systems.

-

Interchangeable Components: No need for field matching or calibration.

-

High Temperature Capable: Optional ETR versions operate up to 260°C.

-

Durable Construction: PPS probe tip and armored options improve longevity.

-

Fast Installation: SpringLoc terminal blocks eliminate special tools.

-

Enhanced EMI/RFI Immunity: Reliable in electrically noisy environments.

FAQ – Frequently Asked Questions

Q1: What is the total system length of this probe?

A1: The 330101-00-96-10-02-05 is a 1-meter system with no extension cable.

Q2: Is this probe compatible with older 3300 series components?

A2: Yes, it is backward compatible with non-XL 3300 5 mm and 8 mm components.

Q3: What shaft size is recommended for radial vibration measurements?

A3: A shaft diameter of at least 76.2 mm (3 in) is recommended for optimal accuracy.

Q4: Can the probe withstand high temperatures?

A4: The standard version supports up to 177°C; the ETR version up to 218°C (probe tip).

Q5: Does this system require recalibration if components are changed?

A5: No. All parts are fully interchangeable without needing recalibration.

Q6: What material is used for the probe’s outer case?

A6: The outer case is made of stainless steel (AISI 303 or 304).

Q7: How is electrical interference managed in this system?

A7: It features enhanced RFI/EMI immunity and CE compliance, no shielded conduit required.

Q8: Can this probe be used in hazardous areas?

A8: Yes. It holds CSA, ATEX, and IECEx certifications for hazardous environments.

Q9: What is the recommended gap voltage setting for radial vibration?

A9: -9 VDC, which corresponds to approximately 1.27 mm (50 mils) gap.

Q10: What is the minimum bend radius for the cable?

A10: The cable requires a minimum bend radius of 25.4 mm (1 inch).

Related Models (Same Series)

| Model Number | Description | Length | Weight |

|---|---|---|---|

| 330101-00-96-10-02-00 | 3300 XL 8 mm Probe, 1m, standard cable | 1.0 m | 0.323 kg |

| 330101-00-96-20-02-05 | 3300 XL 8 mm Probe, 2m, FluidLoc cable | 2.0 m | 0.470 kg |

| 330101-00-96-50-02-05 | 3300 XL 8 mm Probe, 5m, FluidLoc cable | 5.0 m | 0.750 kg |

| 330102-00-20-10-02-00 | 3300 XL 8 mm Probe, armored, 2m | 2.0 m | 0.560 kg |

| 330103-00-05-10-02-00 | Metric 8 mm Probe, M10 thread, 1.5m | 1.5 m | 0.390 kg |

| 330191-00-96-10-02-05 | 3300 XL 8 mm ETR Probe, 1m, FluidLoc | 1.0 m | 0.323 kg |

Popular Bently Nevada Models

| Model Number | Description | Application | Weight |

|---|---|---|---|

| 330104-00-06-10-02 | 8 mm Probe, armored, M10 thread, 0.6 m | Vibration/position monitoring | 0.360 kg |

| 330180-91-05 | 3300 XL Proximitor Sensor, 9m system, DIN mount | Signal conditioning, monitoring | 0.246 kg |

| 3500/42M-01-00 | Proximitor Seismic Monitor Module | Machinery condition monitoring | ~0.5 kg |

| 3500/22M-01-01 | Transient Data Interface Module | Real-time data interface | ~0.4 kg |

| 3500/15-05-01-00 | Power Supply Module | Powering Bently Nevada 3500 system | ~1.1 kg |

| 3500/25-01-01-00 | Keyphasor Module | Shaft speed/reference measurement | ~0.6 kg |

Excellent PLC

Excellent PLC