| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

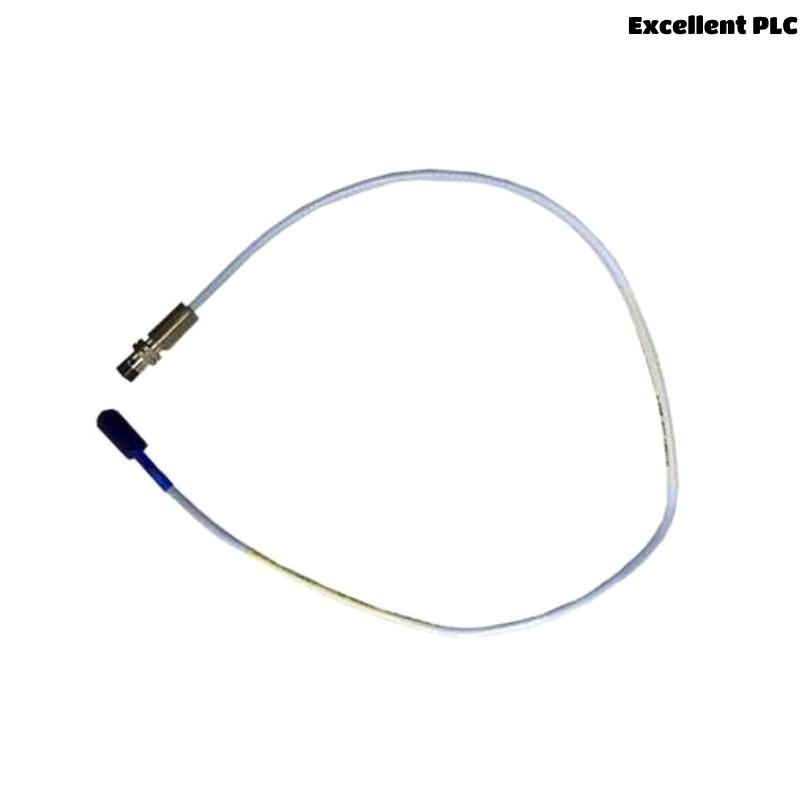

The Bently Nevada 330101-29-52-10-02-00, commonly known as the 3300 XL 8mm Proximity Probe, is a high-precision sensor designed to measure shaft vibration and position in rotating machinery. Renowned for its reliability and accuracy, this probe is part of the trusted 3300 XL series, widely used in critical machinery monitoring systems across industries such as power generation, oil and gas, and heavy manufacturing.

With an 8mm tip diameter, the probe offers excellent sensitivity and resolution to detect subtle shaft movements and vibration patterns, enabling early fault detection and preventive maintenance. It integrates seamlessly with Bently Nevada’s 3300 XL vibration monitoring system, providing essential data to improve machine reliability, reduce unplanned downtime, and extend equipment life.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330101-29-52-10-02-00 |

| Series | 3300 XL |

| Sensor Type | Proximity Probe (Eddy Current) |

| Tip Diameter | 8 mm |

| Tip Style | Flat Face |

| Sensing Range | 2.54 mm (0.100 inch) |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -55°C to +150°C |

| Total Length | 1 meter |

| Connector Type | MIL-C-26482 (standard military-grade connector) |

| Weight | 0.323 kg |

| Probe Body Material | Stainless Steel |

| Protection Rating | IP67 (when properly installed) |

| Output Signal | AC signal proportional to gap distance |

| Mounting Style | Threaded or welded installation options available |

Applications

The 3300 XL 8mm Proximity Probe is widely employed in machinery condition monitoring systems where precise shaft position and vibration measurement are critical. Common applications include:

-

Gas and Steam Turbines – Shaft vibration and position monitoring for early fault detection

-

Centrifugal Compressors – Ensuring rotor stability and balance

-

Motors and Generators – Monitoring shaft movement and alignment

-

Pumps and Fans – Vibration monitoring to prevent failures

-

Hydraulic Turbines – Detection of shaft displacement and bearing wear

-

Industrial Process Equipment – Continuous condition monitoring to improve uptime

Key Advantages

-

High Sensitivity and Accuracy: Detects minute shaft vibrations and displacements with precision.

-

Robust Construction: Stainless steel housing and IP67 rating ensure durability in harsh environments.

-

Reliable Signal Output: Stable AC signal for consistent measurement and diagnostics.

-

Easy Integration: Designed to work seamlessly with Bently Nevada 3300 XL monitoring systems.

-

Flexible Installation: Multiple mounting options suit various machinery configurations.

-

Extended Temperature Range: Suitable for extreme industrial environments.

Frequently Asked Questions (FAQ)

-

Q: What is the sensing range of the 3300 XL 8mm Proximity Probe?

A: The sensing range is approximately 2.54 mm (0.100 inch). -

Q: Can this probe be used with non-Bently Nevada monitoring systems?

A: It is optimized for Bently Nevada 3300 XL systems but can be adapted with suitable signal conditioning. -

Q: What connector type does the probe use?

A: It uses a MIL-C-26482 military-grade connector. -

Q: Is the probe suitable for use in explosive environments?

A: Yes, when installed according to appropriate hazardous location guidelines and enclosures. -

Q: What kind of maintenance is required for the probe?

A: Minimal maintenance is required; regular inspection and cleaning are recommended. -

Q: What is the operating temperature range for the probe?

A: -40°C to +120°C. -

Q: Can the total length be customized?

A: Yes, standard length is 1 meter, but custom lengths can be provided. -

Q: How is the probe mounted?

A: It can be mounted using threaded fittings or welded mounts depending on the application. -

Q: What is the diameter of the probe tip?

A: The probe tip diameter is 8 mm. -

Q: Is the probe compatible with remote monitoring systems?

A: Yes, when connected through compatible 3300 XL monitoring hardware.

Related Models or Similar Series

| Model Number | Tip Diameter | Sensing Range | Connector Type | Typical Application |

|---|---|---|---|---|

| 330101-29-54-10-02-00 | 12 mm | 2.54 mm | MIL-C-26482 | Larger shaft vibration sensing |

| 330101-29-52-10-03-00 | 8 mm | 5 mm | MIL-C-26482 | Extended range proximity |

| 330101-29-51-10-02-00 | 5 mm | 2 mm | MIL-C-26482 | Small tip applications |

| 330101-29-53-10-02-00 | 10 mm | 2.54 mm | MIL-C-26482 | Standard industrial use |

| 330101-29-55-10-02-00 | 15 mm | 2.54 mm | MIL-C-26482 | Heavy-duty industrial |

| 330102-29-52-10-02-00 | 8 mm | 2.54 mm | Bendix connector | Alternative connector type |

Popular Bently Nevada Models

| Model Number | Type | Application | Output | Size (mm) | Weight |

|---|---|---|---|---|---|

| 3300 XL Monitor | Vibration Monitor | Machinery condition monitoring | Analog/Digital | 230 × 175 × 90 | 3.5 kg |

| 3300 XL System Processor | Signal Processing Unit | Multi-channel data acquisition | Digital | 150 × 120 × 70 | 1.2 kg |

| 3500 Series Proximitor | Proximity Sensor | Shaft displacement sensing | AC Signal | Various | 0.15 – 0.3 kg |

| 1701 Meters | Vibration Transmitter | Overall vibration monitoring | 4–20 mA | 120 × 80 × 60 | 0.6 kg |

| 1331 Eddy Current Probes | Proximity Probes | General shaft vibration | AC Signal | Various | 0.2 kg |

| 2300 Vibration Monitor | Portable Monitor | Field vibration analysis | Digital | Handheld device | 1.1 kg |

Excellent PLC

Excellent PLC