| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

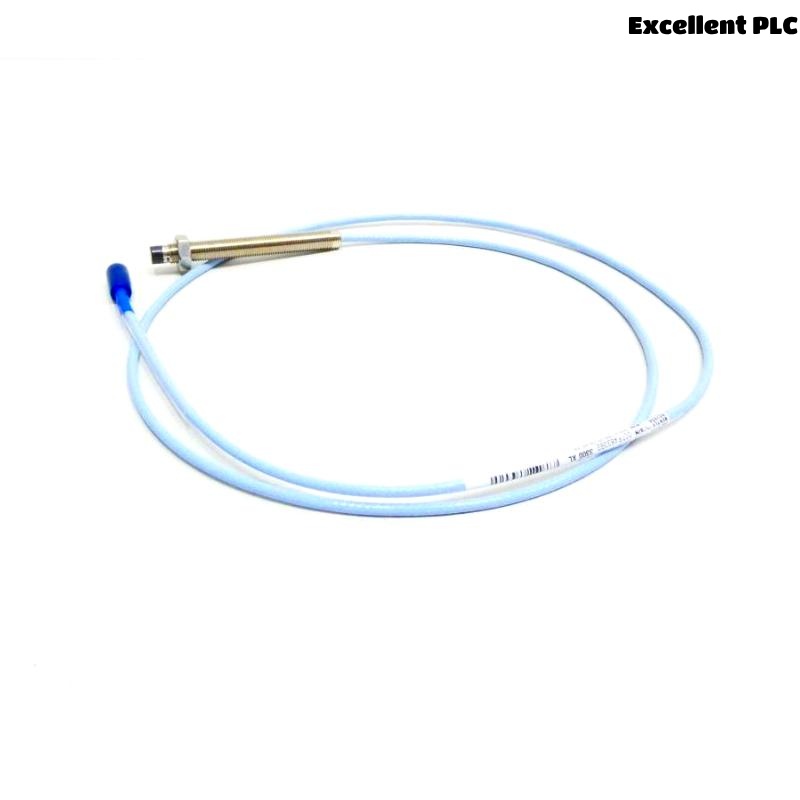

The Bently Nevada 3300 XL 8 mm Proximity Probe is part of the 3300 XL Proximity Transducer System, designed for high-precision vibration and position measurement in fluid-film bearing machines. It outputs a voltage proportional to the distance between probe tip and target, ideal for both static and dynamic monitoring. Fully compliant with API 670, it offers advanced robustness, extended temperature options, and interchangeability of components.

Applications

-

Vibration and position monitoring of rotating machinery

-

Keyphasor reference and overspeed detection

-

Fluid-film bearing condition monitoring

-

Turbine, compressor, and generator shaft position

Advantages

-

Fully compliant with API 670

-

Interchangeable with non-XL 3300 8 mm components

-

High resistance to RFI/EMI and environmental contamination

-

Robust TipLoc and CableLoc design improves mechanical integrity

-

Optional FluidLoc cable to prevent oil ingress

-

Extended temperature and hazardous area certified options

Technical Specifications

| Parameter | Value |

|---|---|

| Total Length | 9.0 m (29.5 ft) |

| Weight | 2.907 kg |

| Probe Diameter | 8.0 mm (0.31 in) |

| Material | PPS tip, stainless steel body |

| Cable Type | 75 Ω triaxial with ClickLoc connectors |

| Operating Temperature | -52°C to +177°C (standard) |

| Extended Temp (optional) | up to +218°C tip, +260°C cable |

| Linear Range | 0.25 to 2.3 mm |

| Recommended Gap | 1.27 mm (50 mils) |

| Frequency Response | 0 to 10 kHz (+0, -3 dB) |

| Output Sensitivity | 200 mV/mil |

| Compliance | CE, FCC, SIL 2/3, ATEX, IECEx, CSA |

FAQ

Q1: What is the primary use of the 3300 XL 8 mm probe?

A1: It measures vibration and shaft position in critical rotating machinery.

Q2: Is it interchangeable with older 3300 series components?

A2: Yes, it is backward compatible with non-XL 5 mm and 8 mm systems.

Q3: What is the standard operating temperature range?

A3: From -52°C to +177°C for the standard probe.

Q4: What certifications does it meet?

A4: It meets API 670, CE, FCC, ATEX, IECEx, SIL 2/3.

Q5: Can it be used in hazardous areas?

A5: Yes, with the appropriate barriers and approvals.

Q6: How is the probe protected from environmental damage?

A6: Optional connector protectors and FluidLoc cables enhance protection.

Q7: Does it support extended temperature environments?

A7: Yes, with the ETR version rated up to +218°C at the tip and +260°C at the cable.

Q8: What is the recommended gap setting?

A8: 1.27 mm (50 mils) to achieve optimal linearity.

Q9: What material is the probe tip made of?

A9: It is made of durable PPS plastic encapsulation.

Q10: Is special calibration required for non-steel targets?

A10: Yes, custom calibration for materials other than AISI 4140 is available.

Recommended Related Models

| Model Number | Description | Length | Weight |

|---|---|---|---|

| 330101-00-05-10-02-05 | 3300 XL 8 mm Probe, std cable | 0.5 m | 0.2 kg |

| 330101-00-10-10-02-05 | 3300 XL 8 mm Probe, std cable | 1.0 m | 0.25 kg |

| 330102-00-20-10-02-00 | 3300 XL 8 mm Probe, armored | 2.0 m | 0.4 kg |

| 330105-02-12-05-02-00 | 3300 XL Reverse Mount Probe | 0.5 m | 0.2 kg |

| 330191-00-90-10-02-05 | 3300 XL ETR 8 mm Probe | 9.0 m | 3.0 kg |

| 330140-00-50-10-02-00 | 3300 XL Smooth Case Probe | 5.0 m | 0.6 kg |

Popular Bently Nevada Models

| Model Number | Description | Length | Weight |

|---|---|---|---|

| 330104-00-06-10-02-00 | 3300 XL 8 mm Probe, armored M10 | 0.6 m | 0.22 kg |

| 330106-05-30-10-02-00 | 3300 XL Reverse Mount Probe M10 | 3.0 m | 0.35 kg |

| 330180-91-CN | 3300 XL Proximitor Sensor | 9.0 m | 0.25 kg |

| 330130-030-00-00 | 3300 XL Extension Cable | 3.0 m | 0.1 kg |

| 3500/42M-01-00 | 3500/42M Proximitor Seismic Monitor | N/A | 1.2 kg |

| 3500/44M-02-00 | 3500/44M Aeroderivitive Vibration | N/A | 1.5 kg |

Excellent PLC

Excellent PLC