| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

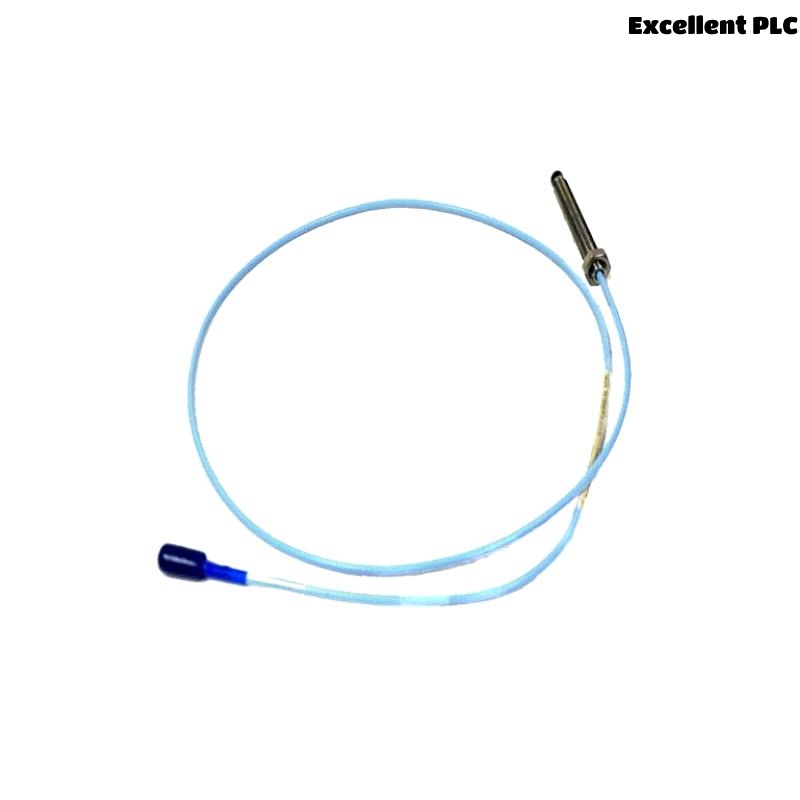

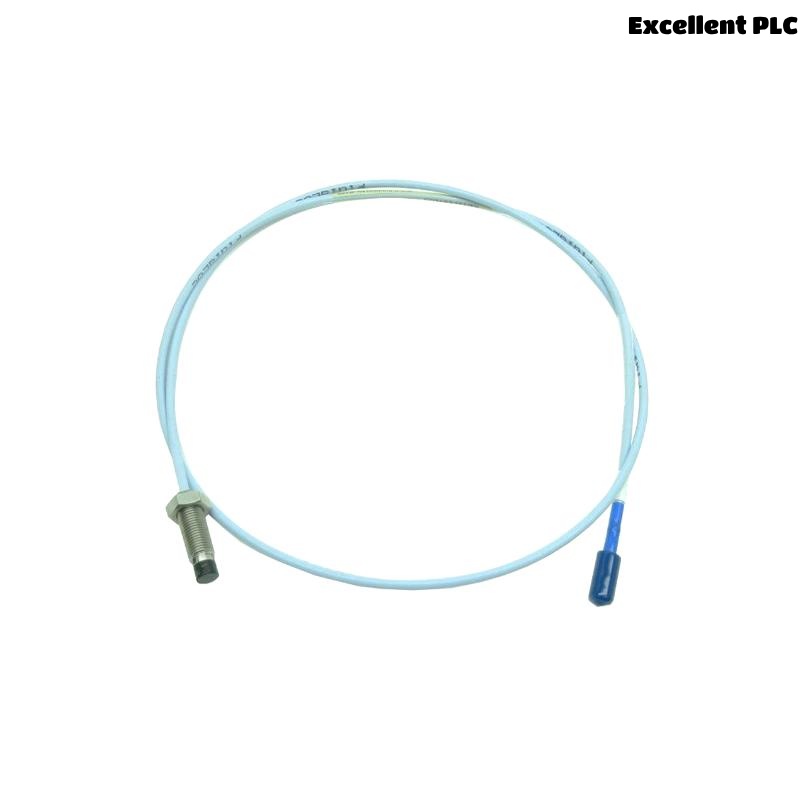

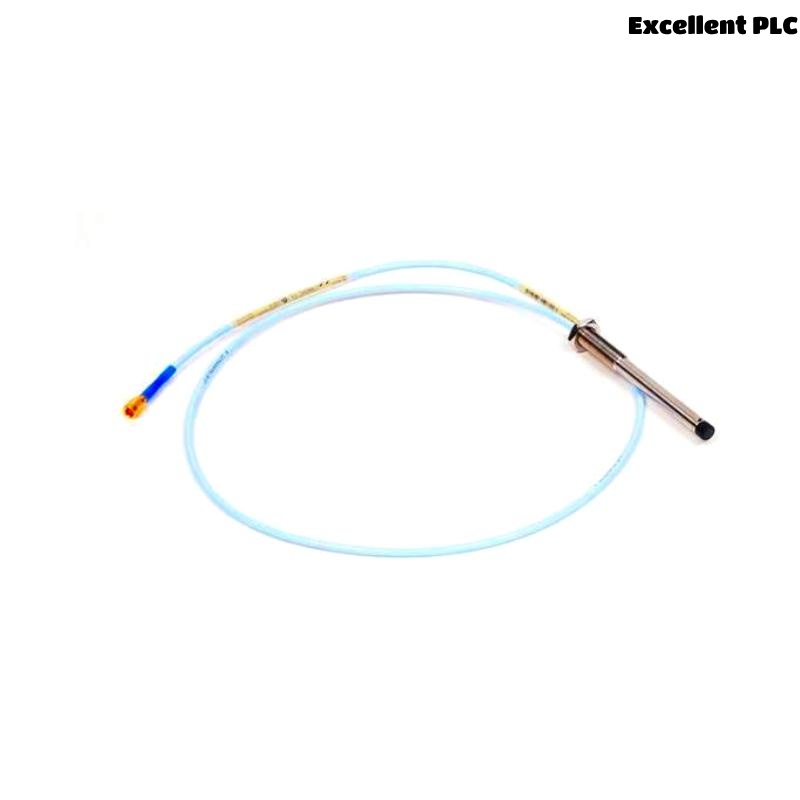

The Bently Nevada 330101-36-80-10-02-05 is a high-precision proximity probe from the 3300 XL series, designed for monitoring shaft displacement and vibration in rotating machinery. This probe features an 8mm diameter sensing tip and employs eddy-current technology to deliver reliable, non-contact measurements that are critical in industrial condition monitoring.

Built to withstand demanding industrial environments, the 3300 XL 8mm probe provides accurate, repeatable measurements that help detect early signs of machinery wear, imbalance, or misalignment. The rugged stainless steel construction, combined with advanced signal integrity and noise rejection capabilities, ensures long-term durability and dependable performance.

This model is commonly used in critical rotating equipment across multiple industries such as power generation, oil and gas, manufacturing, and mining. It integrates seamlessly with Bently Nevada 3300 XL monitoring systems, enabling effective asset protection and maintenance optimization.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330101-36-80-10-02-05 |

| Series | 3300 XL Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Sensing Range | 0.25 mm to 2.54 mm (typical) |

| Measurement Type | Shaft displacement and vibration monitoring |

| Output Signal | Analog AC output proportional to displacement |

| Operating Temperature Range | -40°C to +121°C |

| Total Length | 1 meter |

| Connector Type | MIL-C-26482 military style connector |

| Probe Housing Material | Stainless steel |

| Weight | 0.323 kg |

| Cable Type | Shielded, low-noise cable |

| Mounting Options | Threaded or flange mount |

| Compliance Standards | IEC vibration monitoring standards, ISO |

Applications

The 3300 XL 8mm proximity probe is widely used for monitoring critical rotating equipment in various industries, including:

-

Power Generation: Turbines, generators, and motor shaft vibration and displacement monitoring.

-

Oil and Gas: Pumps, compressors, and rotating machinery condition monitoring.

-

Mining and Minerals Processing: Crushers, mills, conveyors, and other heavy machinery.

-

Pulp and Paper: Equipment vibration monitoring to avoid unscheduled downtime.

-

Manufacturing: Heavy-duty motors, gearboxes, and rotating shafts.

-

Aerospace & Defense: High-precision monitoring of rotating components in engines.

Advantages

-

Accurate Non-contact Measurement: Eddy-current sensing ensures precise displacement and vibration data without mechanical wear.

-

Rugged Construction: Stainless steel housing protects against harsh environmental conditions including temperature extremes and contaminants.

-

Long Service Life: Designed for reliable, maintenance-free operation over extended periods.

-

Flexible Installation: Multiple mounting options including threaded and flange configurations.

-

Compatibility: Seamlessly integrates with Bently Nevada 3300 XL monitoring systems.

-

Enhanced Signal Integrity: Shielded cables and advanced probe design minimize electrical noise.

-

Wide Operating Temperature: Suitable for use in extreme industrial environments.

-

Standardized Connectors: Military-style connectors ensure reliable electrical connections.

-

Early Fault Detection: Provides critical data for predictive maintenance to reduce downtime.

-

Global Support: Backed by Bently Nevada’s extensive technical and service network.

Frequently Asked Questions (FAQs)

1. What measurement principle does the 3300 XL proximity probe use?

It operates on eddy-current technology for contactless measurement of shaft displacement.

2. What is the sensing range of this 8mm probe?

Typically, it detects displacement from 0.25 mm up to 2.54 mm.

3. Can this probe function in high-temperature environments?

Yes, it is rated to operate between -40°C and +121°C.

4. What kind of output signal does it provide?

An analog AC signal proportional to the shaft’s displacement.

5. Is the cable length customizable?

Yes, standard length 1 meter, but longer cables can be provided upon request.

6. How is the probe mounted?

It supports both threaded and flange mounting depending on the installation requirement.

7. What type of connector does the probe use?

It uses a MIL-C-26482 connector for secure and reliable electrical connection.

8. How durable is the probe?

With a stainless steel housing and rugged design, it withstands harsh environments.

9. Can it be used with other condition monitoring systems?

Though optimized for Bently Nevada 3300 XL systems, it may work with other compatible systems supporting eddy-current probes.

10. How often should the probe be serviced or calibrated?

Generally, annual calibration and inspection are recommended to maintain measurement accuracy.

Related Models from the Same Series

| Model Number | Description | Probe Tip Diameter | Cable Length | Weight |

|---|---|---|---|---|

| 330101-33-66-10-02-05 | 3300 XL Proximity Probe, 8mm tip | 8 mm | 10 m | 0.15 kg |

| 330101-36-80-10-02-06 | 3300 XL High-Temperature Probe | 8 mm | 15 m | 0.18 kg |

| 330101-33-66-10-02-01 | 3300 XL Proximity Probe, 5mm tip | 5 mm | 10 m | 0.12 kg |

| 330101-33-66-10-02-03 | 3300 XL Proximity Probe, 12mm tip | 12 mm | 10 m | 0.18 kg |

| 330101-33-66-10-02-08 | 3300 XL Probe with Flange Mount | 8 mm | 15 m | 0.19 kg |

| 330101-33-66-10-02-09 | 3300 XL Probe with Extended Cable | 8 mm | 20 m | 0.25 kg |

Popular Bently Nevada Models

| Model Number | Description | Application | Weight |

|---|---|---|---|

| 330104-01-01-05 | 3300 XL Proximity Probe System | Shaft vibration monitoring | 0.20 kg |

| 330190-01-02-02 | 3300 XL Monitor Module | Vibration data processing | 0.50 kg |

| 330202-01-00-05 | 3300 XL Keyphasor Probe | Speed and phase reference | 0.15 kg |

| 330401-01-00-02 | 3300 XL Monitor Interface Module | Signal conditioning | 0.45 kg |

| 330200-01-02-10 | 3300 XL Vibration Monitor with Display | On-site vibration analysis | 2.0 kg |

| 330206-01-01-01 | 3300 XL Proximity Probe Cable | Shielded cable assembly | Varies |

Excellent PLC

Excellent PLC