| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

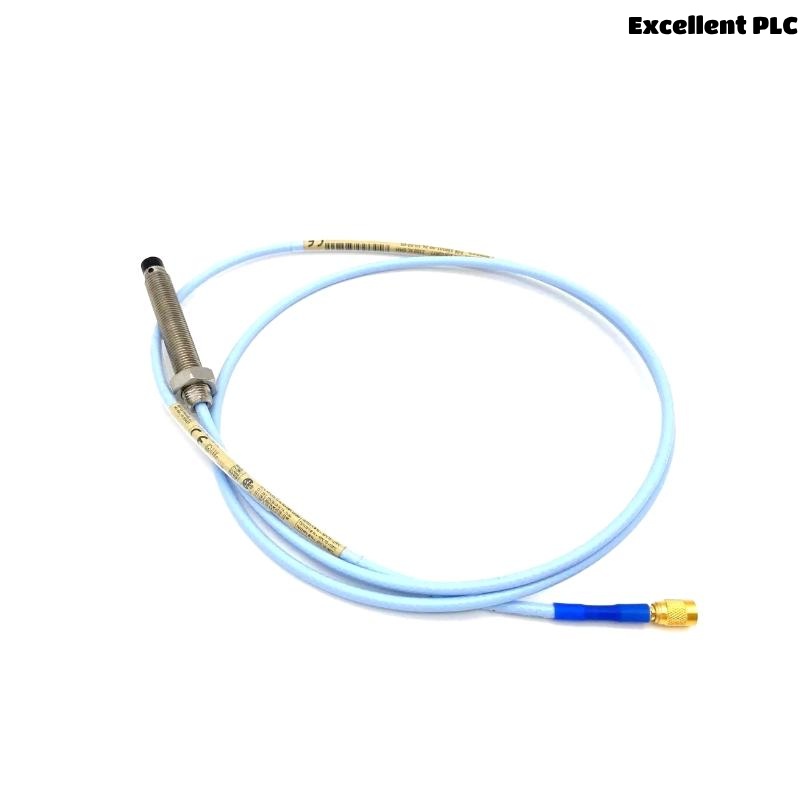

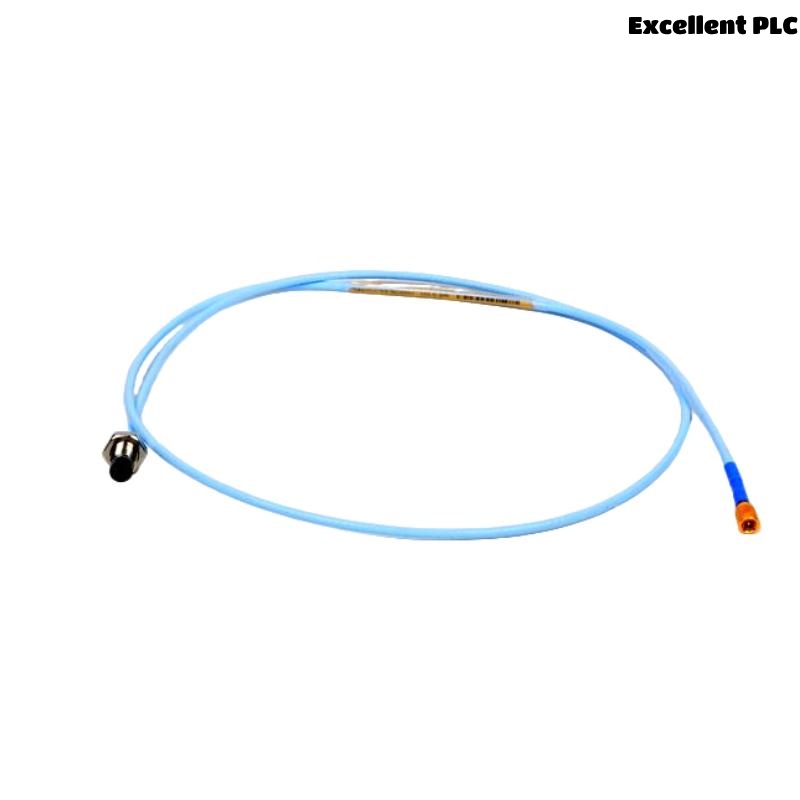

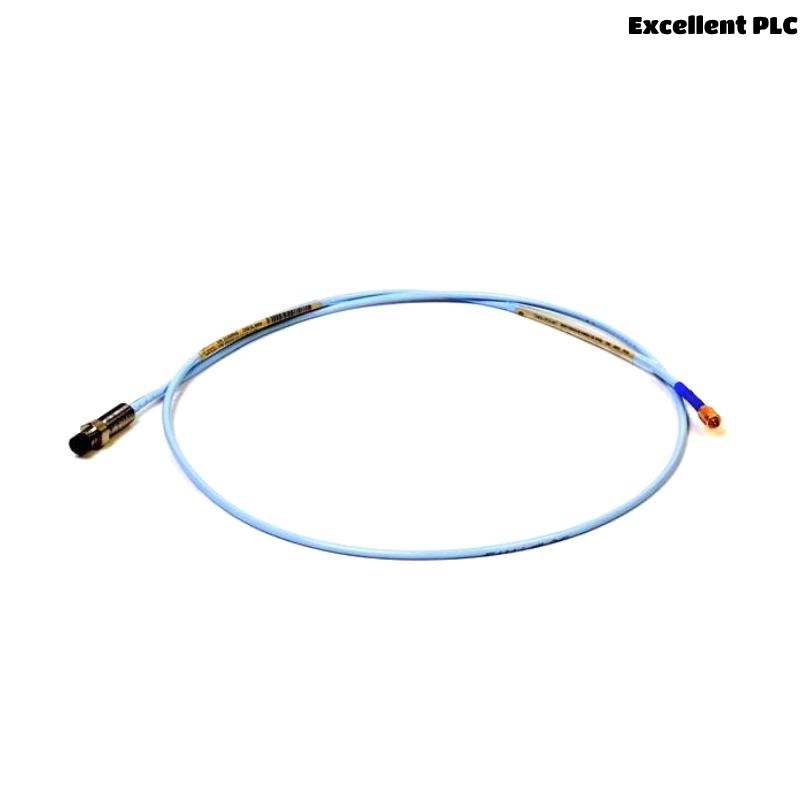

The Bently Nevada 330101-37-57-10-02-05 is part of the 3300 XL 8mm Proximity Transducer System, designed and manufactured by Bently Nevada, a Baker Hughes business. It is a high-performance non-contact proximity probe used primarily for vibration, position, and speed measurements in rotating machinery.

This particular model, with its 8mm probe tip and configured extension cable and Proximitor, is built to deliver exceptional stability, interchangeability, and linearity over extended ranges. It is fully API 670 compliant and widely deployed in industries such as power generation, oil & gas, chemical processing, and manufacturing, where monitoring of critical rotating equipment is essential for predictive maintenance and failure prevention.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-37-57-10-02-05 |

| Series | Bently Nevada 3300 XL 8mm Proximity Probe Series |

| System Type | Non-contact Eddy Current Proximity Transducer |

| Shaft Diameter Compatibility | Typically ≥25 mm (1 in) |

| Tip Diameter | 8 mm (0.31 in) |

| Total Length | 1 meter |

| Thread Type | 3/8-24 UNF or M10 x 1 |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| System Accuracy | ±5% of full-scale typical |

| Frequency Response | Up to 10 kHz |

| Operating Temperature (Probe) | -35°C to +177°C (-31°F to +351°F) |

| Operating Temperature (Cable) | -51°C to +177°C (-60°F to +351°F) |

| Environmental Protection | IP65 / IEC 60529 rated |

| Material (Probe Housing) | Stainless steel |

| Mounting | Threaded mount |

| Certifications | CE, ATEX (for hazardous area configurations), RoHS |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 330101-37-57-10-02-05 proximity probe is a critical component in vibration and position monitoring systems for rotating equipment. Key application areas include:

-

Turbomachinery Monitoring (turbines, compressors, pumps)

-

Journal and Thrust Bearing Clearance Measurement

-

Shaft Vibration & Displacement Tracking

-

Rotational Speed Detection

-

Condition Monitoring in Power Plants

-

Predictive Maintenance in Oil & Gas Facilities

-

Heavy-Duty Machinery in Steel, Pulp & Paper Industries

-

API 670-compliant safety and shutdown systems

The probe’s robust construction and precise signal fidelity make it ideal for long-term deployment in both benign and hazardous industrial environments.

Product Advantages

-

Industry-Leading Accuracy: Delivers high-precision shaft position and vibration data critical for machinery health diagnostics.

-

API 670 Compliant: Meets global standards for safety, performance, and reliability in vibration monitoring.

-

Wide Temperature Tolerance: Operates reliably in extreme thermal environments (up to 177°C).

-

Modular Configuration: Interchangeable components (probe, cable, proximitor) for simplified field replacement.

-

Rugged Construction: Stainless steel housing and sealed design ensure durability under harsh industrial conditions.

-

Ease of Installation: Threaded mounting and factory-configured lengths reduce installation time.

-

Non-Contact Measurement: No mechanical wear, reducing maintenance and enhancing lifespan.

-

Versatile Deployment: Compatible with various shaft sizes, mounting locations, and machinery types.

-

Diagnostic Compatibility: Fully integrated with Bently Nevada monitoring systems like 3500 and ADAPT.

-

Proven Track Record: Globally used in mission-critical infrastructure for decades.

Frequently Asked Questions (FAQs)

-

What is the primary use of the 330101-37-57-10-02-05 probe?

It is used for non-contact measurement of shaft vibration and position in rotating machinery. -

What does the “8mm” refer to in the model description?

It refers to the diameter of the probe tip, which determines the sensing area and mounting configuration. -

Can the probe operate in high-temperature environments?

Yes, the probe and cable are rated up to 177°C (351°F), suitable for high-heat applications. -

Is this probe compatible with all Bently Nevada proximitor modules?

It is designed to be used with the 3300 XL Proximitor Sensor, not legacy proximitor modules. -

Is it API 670 compliant?

Yes, the entire 3300 XL system (probe, cable, proximitor) is compliant with API 670 standards. -

Can I replace just the probe or cable if one fails?

Yes, the modular design allows for individual replacement without re-calibrating the entire system. -

What type of machinery benefits most from this probe?

Turbines, compressors, pumps, and motors—especially in critical applications like power plants and refineries. -

How is the probe mounted?

It typically uses a threaded mount (3/8-24 UNF or M10) into a machined bracket or sensor block. -

Does the cable require special shielding?

The extension cable is factory-shielded and designed to reduce EMI in industrial environments. -

Can this model be used in hazardous locations?

Yes, when paired with the correct ATEX/IECEx certified proximitor and installation practices.

Related Models in the 3300 XL 8mm Series

| Model Number | Cable Length | Tip Diameter | Thread Type | Application | Weight |

|---|---|---|---|---|---|

| 330101-00-05-10-02-00 | 5 meters | 8 mm | 3/8-24 UNF | Standard probe for compressors | 0.6 kg |

| 330101-00-20-10-02-00 | 7 meters | 8 mm | M10 x 1 | European machinery setups | 0.7 kg |

| 330101-00-12-10-01-00 | 9 meters | 8 mm | 3/8-24 UNF | General purpose | 0.8 kg |

| 330104-00-05-10-02-00 | 5 meters | 11 mm (oversize) | 1/2-20 UNF | Large shaft applications | 0.9 kg |

| 330101-00-14-10-01-00 | 8 meters | 8 mm | 3/8-24 UNF | Long-distance installs | 0.8 kg |

| 330102-00-08-10-01-00 | 6 meters | 8 mm | M10 x 1 | API pump systems | 0.7 kg |

Popular Models from Bently Nevada (Other Series)

| Model Number | Description | Application | Compatibility | Weight |

|---|---|---|---|---|

| 3500/22M | Transient Data Interface (TDI) | Data acquisition | 3500 Series Rack | 1.2 kg |

| 330130-040-00 | XL Extension Cable, 4m | Probe cable extension | 3300 XL Probes | 0.4 kg |

| 3300/20 | Dual Vibration Monitor | Legacy machinery monitoring | 3300/25 Proximitor | 1.3 kg |

| 330400-02-12-10-01-00 | Velomitor Piezoelectric Sensor | Vibration monitoring | Bently Monitoring Systems | 0.6 kg |

| 7200-50-06-03-00 | Proximitor Monitor Card | Legacy proximity monitoring | 7200 Series | 1.1 kg |

| ADAPT 3701/55 | Advanced Machinery Protection Monitor | Vibration + process | ADAPT System | 1.5 kg |

Excellent PLC

Excellent PLC