| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

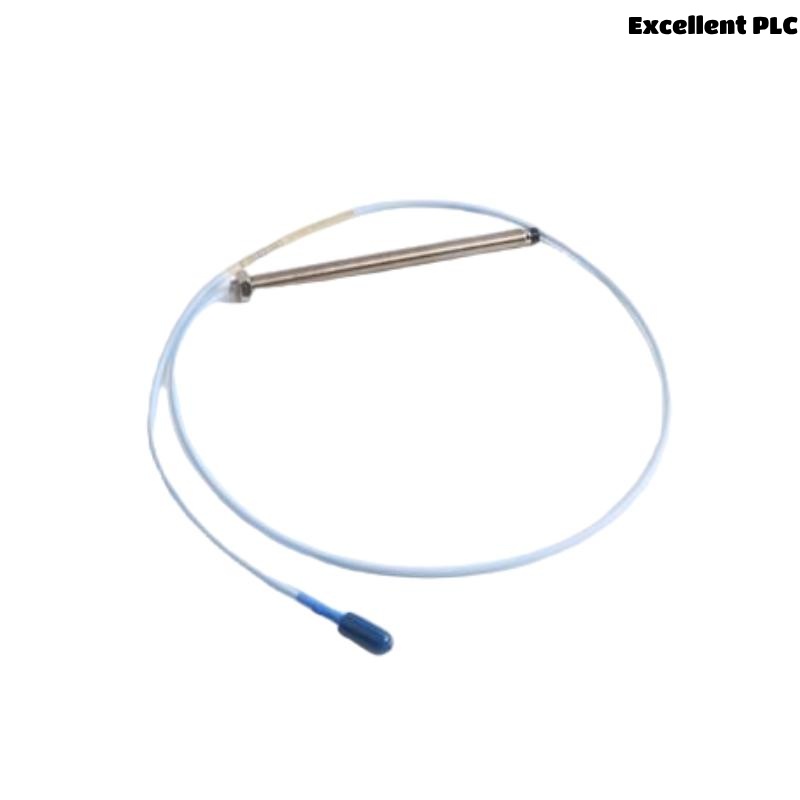

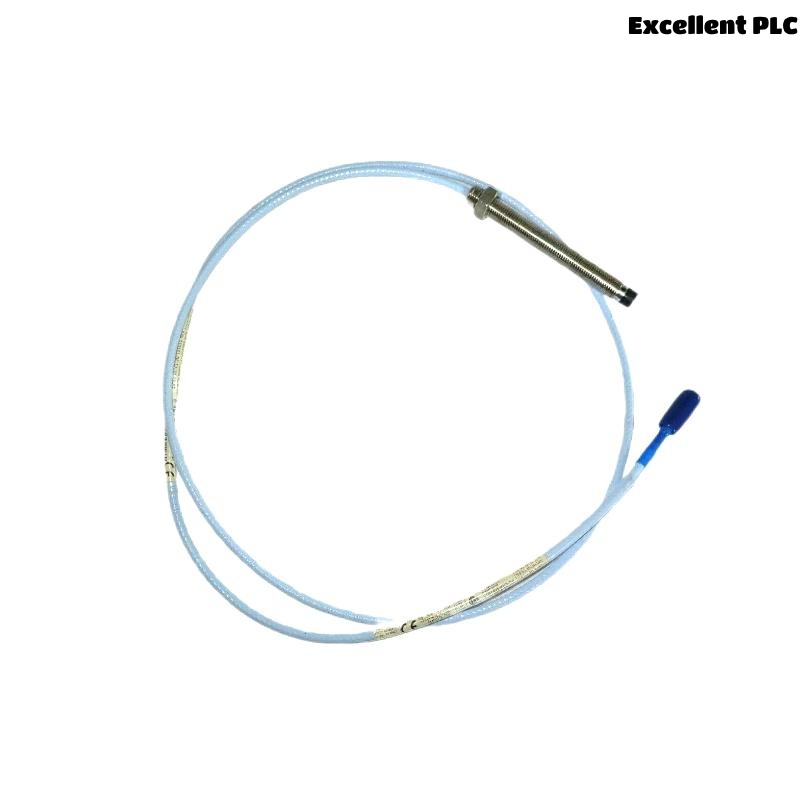

The Bently Nevada 330101-40-60-05-02-CN is a precision-engineered proximity probe belonging to the 3300 XL 8mm Proximity Transducer System, widely recognized in the industrial world for its accuracy, durability, and API 670 compliance. Designed for critical machinery monitoring, this model provides non-contact vibration and position measurements for rotating machinery.

With an 8mm probe tip, 0.5 meter extension cable, and matching Proximitor sensor, the 330101-40-60-05-02-CN is built for rigorous environments such as gas turbines, steam turbines, compressors, and other high-speed rotating equipment. It features superior mechanical robustness, precise linearity, and immunity to electromagnetic interference, making it an ideal choice for industrial predictive maintenance systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-40-60-05-02-CN |

| Series | 3300 XL 8mm Proximity Probe |

| Sensing Technology | Eddy Current, Non-contact |

| Tip Diameter | 8 mm (0.315 in) |

| Total Length | 0.5 meter |

| Thread Type | M10 x 1 threaded mount |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) ±5% |

| Frequency Response | DC to 10 kHz |

| Shaft Target Material | 4140 Steel or equivalent ferromagnetic materials |

| Operating Temperature | Probe: –35°C to +177°C (–31°F to +351°F) |

| Storage Temperature | –40°C to +200°C (–40°F to +392°F) |

| Environmental Protection | IP65 / IEC 60529 |

| Cable Insulation Material | FEP (Fluorinated Ethylene Propylene) |

| Housing Material | Stainless Steel |

| Certifications | CE, RoHS, ATEX (when used with certified Proximitor sensor) |

| Weight | 0.161 kg |

Product Applications

The 330101-40-60-05-02-CN proximity probe is engineered for precision monitoring of shaft dynamics and position in critical rotating machinery. It plays a crucial role in:

-

Steam and Gas Turbine Monitoring

-

Compressor Shaft Vibration Measurement

-

Thrust Bearing Position Monitoring

-

Motor and Generator Shaft Alignment

-

Speed Measurement and Rotor Positioning

-

API 670-compliant machinery protection systems

-

Petrochemical, Power Generation, and Heavy Industries

Its accurate, non-contact operation enables early detection of mechanical faults such as imbalance, misalignment, and shaft whip, helping facilities avoid catastrophic failures.

Product Advantages

-

API 670 Compliance: Meets global standards for vibration monitoring in critical rotating machinery.

-

High Linear Accuracy: Delivers stable, repeatable measurements with minimal drift across long service periods.

-

Rugged Industrial Design: Stainless steel housing and FEP cable insulation ensure longevity in high-temperature, corrosive, or vibrating environments.

-

Wide Operating Range: Capable of measuring displacement and vibration across a large temperature and frequency range.

-

Modular Configuration: Interchangeable probe, cable, and proximitor components minimize downtime during maintenance.

-

Electromagnetic Immunity: Built-in shielding reduces signal distortion from ambient electrical noise.

-

Easy Installation: Threaded probe design ensures fast and secure mounting in tight spaces.

-

Global Compatibility: “CN” suffix indicates configuration for Chinese markets or specifications.

-

Low Lifecycle Cost: Long service life with minimal calibration or replacement needs.

-

Diagnostic Integration: Seamlessly interfaces with Bently Nevada’s 3500 and ADAPT systems.

Frequently Asked Questions (FAQs)

-

What does the “CN” suffix stand for?

It typically indicates a configuration optimized or certified for China, including documentation or certification differences. -

Can this probe be used with older 7200 series Proximitor sensors?

No, it is designed for compatibility with the 3300 XL Proximitor sensor only. -

What is the measurement principle behind this probe?

It uses eddy current sensing to detect changes in the gap between the probe and a ferromagnetic shaft surface. -

Is the probe suitable for hazardous environments?

Yes, when used with certified Proximitor sensors and proper installation, it is ATEX compliant. -

What’s the maximum shaft diameter this probe can monitor?

Generally designed for shafts ≥25 mm (1 inch) for optimal sensitivity and signal stability. -

How long is the service life of this probe?

Under normal operating conditions, 10+ years of reliable operation is expected. -

Is field calibration required?

No, factory calibration is provided; only system verification is recommended during installation. -

Can the extension cable be cut or spliced?

No, altering cable length affects system calibration. Use only factory-matched components. -

What is the maximum cable length allowed?

Standard configurations range from 0.5 to 9 meters, depending on the application and signal requirements. -

How does it integrate with Bently Nevada 3500 systems?

It connects via the Proximitor sensor to the input channels of the 3500 machinery protection system.

Related Models from the 3300 XL 8mm Series

| Model Number | Tip Diameter | Cable Length | Thread Type | Mounting | Weight |

|---|---|---|---|---|---|

| 330101-00-08-10-02-00 | 8 mm | 8 meters | M10 x 1 | Threaded | 0.7 kg |

| 330101-00-05-10-01-00 | 8 mm | 5 meters | 3/8-24 UNF | Threaded | 0.7 kg |

| 330101-00-09-10-01-00 | 8 mm | 9 meters | 3/8-24 UNF | Threaded | 0.8 kg |

| 330101-00-14-10-01-00 | 8 mm | 14 meters | 3/8-24 UNF | Threaded | 0.9 kg |

| 330104-00-05-10-02-00 | 11 mm | 5 meters | 1/2-20 UNF | Oversized Shaft | 0.9 kg |

| 330102-00-06-10-01-00 | 8 mm | 6 meters | M10 x 1 | Threaded | 0.75 kg |

Popular Bently Nevada Models (Other Product Lines)

| Model Number | Description | Application | Compatibility | Weight |

|---|---|---|---|---|

| 3500/22M | Transient Data Interface (TDI) | Data acquisition | 3500 Series Rack | 1.2 kg |

| 330130-040-00 | XL Extension Cable, 4m | Probe cable extension | 3300 XL Proximity Probes | 0.4 kg |

| 3300/20 | Dual Vibration Monitor | Vibration monitoring | 3300/25 Proximitor | 1.3 kg |

| 330400-02-12-10-01-00 | Velomitor Piezoelectric Velocity Sensor | Velocity monitoring | Bently Nevada Systems | 0.6 kg |

| ADAPT 3701/55 | Advanced Protection + Diagnostic Module | Real-time machinery health | ADAPT Suite | 1.5 kg |

| 7200-50-06-03-00 | Legacy Proximitor Monitoring Card | Signal Conditioning | 7200 Series Systems | 1.1 kg |

Excellent PLC

Excellent PLC