| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

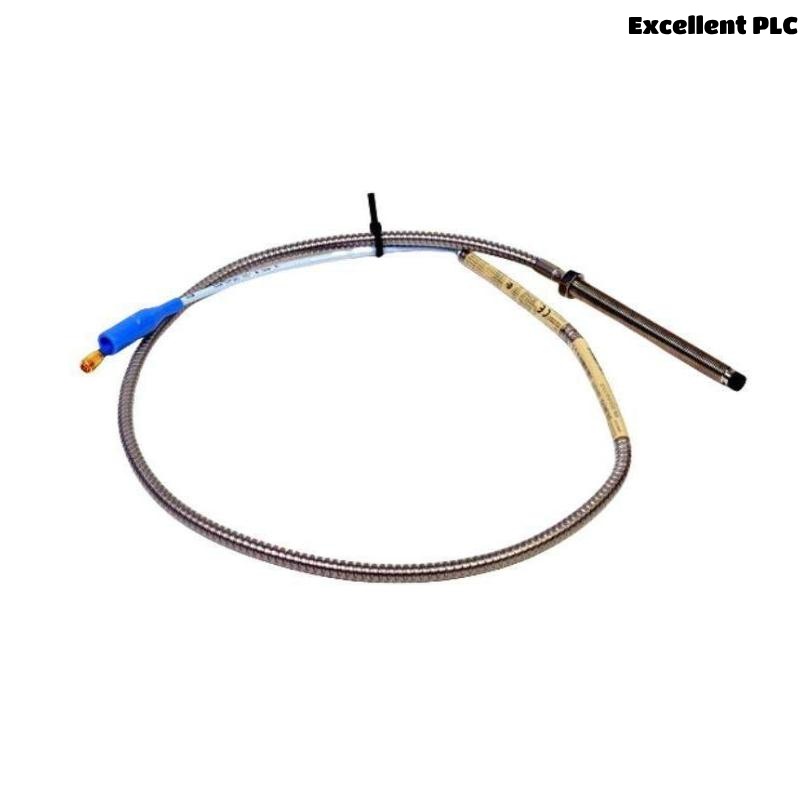

The Bently Nevada 330102-00-12-10-02-05 is a high-precision component from the 3300 XL 8mm Proximity Transducer System series, developed by Bently Nevada, a GE-owned brand recognized for its world-class vibration monitoring solutions. This particular model is part of a proximity probe system designed for continuous, non-contact measurement of shaft position and vibration in critical rotating machinery.

The 3300 XL 8mm system is renowned for its rugged design, superior EMI/RFI resistance, and compatibility with API 670 standards. The probe works seamlessly with matching extension cables and proximitor sensors to form a complete monitoring loop for proximity and vibration analysis, making it a foundational part of condition monitoring systems across industries.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330102-00-12-10-02-05 |

| Series | 3300 XL 8mm Proximity Probe |

| Manufacturer | Bently Nevada (GE) |

| Sensing Range | 2 mm (80 mils) typical |

| Connector Type | Miniature coaxial |

| Target Material | 4140 Steel (calibrated per API 670 standard) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linear Range | 0.25 mm to 2.0 mm |

| Probe Tip Diameter | 8 mm |

| Thread Type | 3/8-24 UNF-2A |

| Mounting | Threaded or bracket mounted |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Relative Humidity | 0 to 95% (non-condensing) |

| Shock Resistance | 1000 g, 0.5 ms duration |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Dimensions (L x Ø Tip) | Probe Length: 2.0 in (50.8 mm), Tip: 8 mm diameter |

| Compliance | API 670, CE, RoHS |

| Housing Material | Stainless Steel (probe & connector) |

Product Applications

The 330102-00-12-10-02-05 proximity probe is utilized extensively in:

-

Steam and Gas Turbines

Monitoring shaft vibration and axial position to prevent catastrophic failures. -

Compressors and Expanders

Ensures stable operation through precise monitoring of rotating components. -

Pumps and Motors

Provides early fault detection by measuring dynamic shaft movement. -

Gearboxes and Generators

Critical for predictive maintenance strategies in mechanical drive systems. -

Refinery and Petrochemical Plants

Forms part of safety shutdown systems governed by API 670. -

Power Plants and Industrial Manufacturing

Used for high-value asset protection and process reliability assurance.

Product Advantages

-

Exceptional Accuracy and Sensitivity

Delivers precise measurements even in challenging industrial environments. -

API 670 Compliance

Fully adheres to industry standards for machinery protection. -

Enhanced RFI/EMI Resistance

Stable signal integrity even in electrically noisy environments. -

High-Temperature Tolerance

Reliable performance up to 177°C, suitable for turbine environments. -

Field-Proven Durability

Stainless steel housing and rugged construction for long service life. -

Modular and Interchangeable

Compatible with other 3300 XL components, simplifying inventory and maintenance. -

Wide Application Versatility

Suitable for virtually any rotating machinery setup requiring non-contact vibration sensing.

Frequently Asked Questions (FAQ)

-

Q: What does the model number 330102-00-12-10-02-05 specify?

A: It identifies specific parameters such as total length (1.0 meter), connector type, and thread type. -

Q: Can this probe be used with other Bently Nevada proximitor sensors?

A: Yes, it is designed to work specifically with 3300 XL series proximitor sensors. -

Q: Is this probe compatible with API 670 specifications?

A: Yes, the 3300 XL 8mm system is designed to meet and exceed API 670 requirements. -

Q: What is the maximum operating temperature?

A: Up to +177°C, allowing installation in high-heat environments like turbines. -

Q: Can it measure both static and dynamic shaft motion?

A: Yes, it measures static position and dynamic vibration (radial and axial). -

Q: What target material is required for accurate readings?

A: Standard calibration is done using AISI 4140 steel; other materials require re-calibration. -

Q: How is the probe mounted?

A: It can be mounted using a threaded port or bracket based on the machinery design. -

Q: What is the typical output sensitivity?

A: 200 mV/mil (7.87 mV/μm), with a linear range of 2 mm. -

Q: Can the cable be replaced in the field?

A: Yes, the probe and extension cable are separate components and can be individually replaced. -

Q: Is this probe suitable for hazardous environments?

A: Yes, when installed with certified proximitor and cable, it supports hazardous area applications.

Related Models (Same Series or Function)

| Model Number | Description |

|---|---|

| 330103-00-12-10-02-05 | 3300 XL 8mm Probe with different cable/thread configuration |

| 330104-00-05-10-02-00 | Reverse mount probe, same series |

| 330130-040-00-00 | XL Extension Cable, 40 ft |

| 330180-91-00 | Proximitor Sensor for 8mm system |

| 330105-02-12-10-02-05 | 8mm probe with armor cable and extended length |

| 330106-05-30-10-02-00 | Long-reach probe version for turbine shaft monitoring |

Popular Bently Nevada Models (High Demand / Cross-Sector Use)

| Model Number | Description |

|---|---|

| 3500/22M | Transient Data Interface Module for 3500 Series |

| 3500/42M | Proximitor Seismic Monitor Module |

| 330104-00-05-10-02-00 | Reverse Mount Probe from 3300 XL Series |

| 330180-51-00 | Proximitor Sensor with standard range and calibration |

| 146031-01 | 3500 Series Keyphasor Module |

| 3300/20-05-03-01-00-00 | Dual Vibration Monitor |

Excellent PLC

Excellent PLC