| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Description

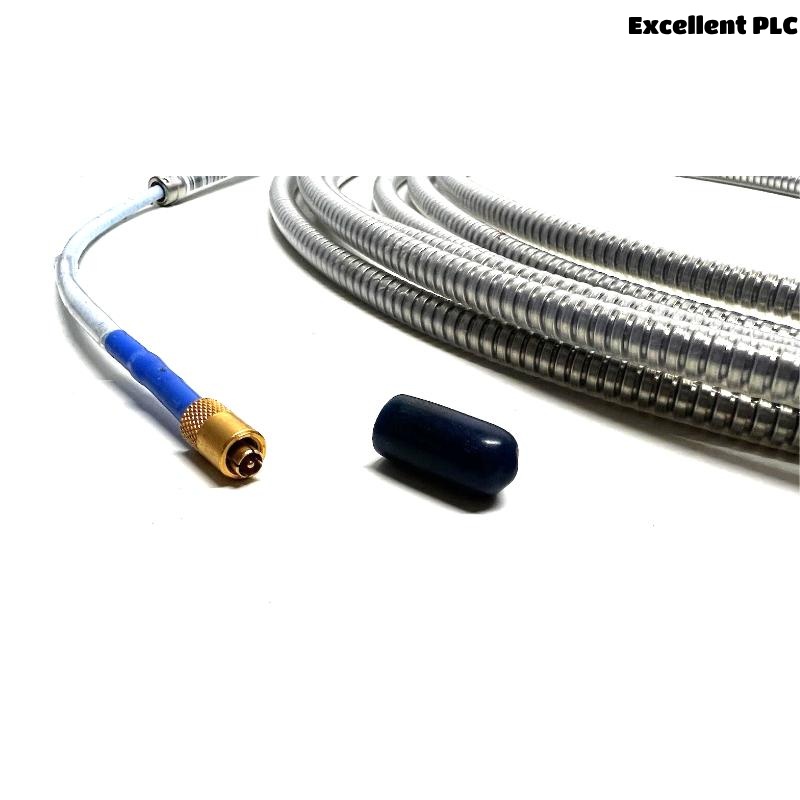

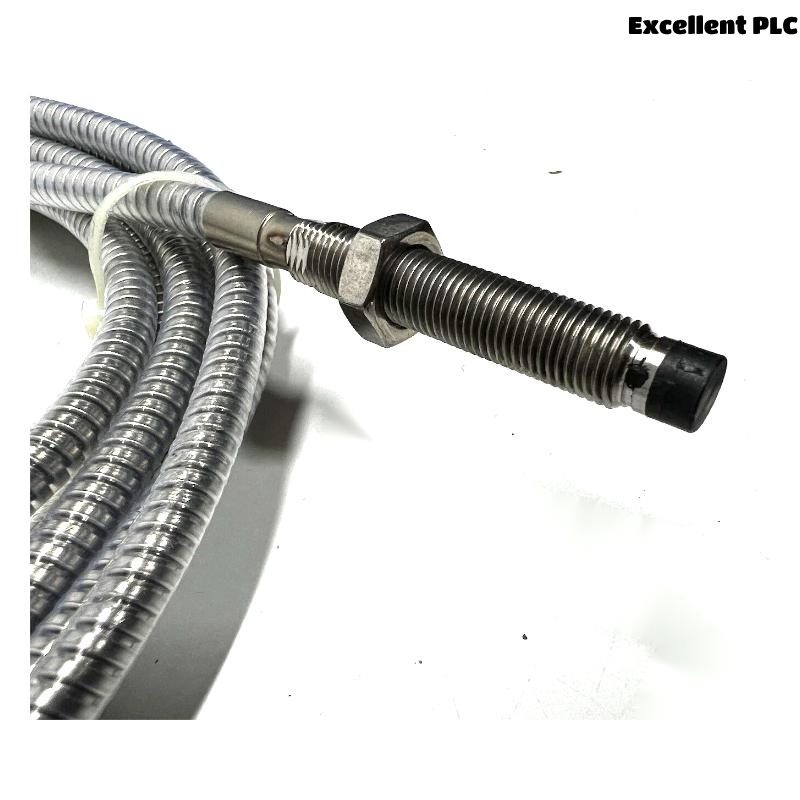

The Bently Nevada 330102-00-20-10-01-05 is part of the 3300 XL 8 mm Proximity Transducer System, designed for precise vibration and position measurement in fluid-film bearing machines. It offers advanced performance, full interchangeability of components, and meets API 670 standards for linearity, accuracy, and temperature stability. Featuring a rugged armored cable for protection, it ensures long-term reliability in demanding industrial environments.

Applications

-

Vibration and position monitoring of rotating machinery

-

Keyphasor and speed measurement

-

Fluid-film bearing machines

-

Turbines, compressors, and motors in oil, gas, and power generation

Advantages

-

API 670 compliant performance

-

Full component interchangeability without calibration

-

Improved RFI/EMI immunity for reliable operation

-

Rugged armored construction for harsh environments

-

Extended temperature options available

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Tip Diameter | 8.0 mm |

| Thread Size | 3/8-24 UNF |

| Total Length | 1.0 m |

| Weight | 0.323 kg |

| Case Material | Stainless Steel |

| Cable Type | Armored |

| Linear Range | 2 mm (80 mils) |

| Recommended Gap | 1.27 mm (50 mils) |

| Operating Temperature | -52°C to +177°C |

| Storage Temperature | -52°C to +177°C |

| Humidity Resistance | ≤3% ASF variation in 93% RH |

| Frequency Response | 0–10 kHz |

| Minimum Target Diameter | 15.2 mm |

FAQ

Q1: What is the main use of the 330102 probe?

A1: It is used for vibration and position monitoring in rotating machinery with fluid-film bearings.

Q2: Does it meet API standards?

A2: Yes, it fully complies with API 670 requirements.

Q3: Can components be mixed with other 3300 series?

A3: Yes, it is backward compatible and interchangeable with non-XL 3300 8 mm components.

Q4: What is the recommended gap setting?

A4: Approximately 1.27 mm (50 mils) or -9 VDC.

Q5: Is this probe suitable for high-temperature environments?

A5: Yes, extended temperature versions are available for up to +218°C.

Q6: What is the minimum shaft diameter for accurate measurement?

A6: Recommended minimum shaft diameter is 76.2 mm (3 inches).

Q7: Does it require special installation tools?

A7: No, thanks to ClickLoc connectors and SpringLoc terminal strips.

Q8: How is the cable protected?

A8: The probe includes a rugged stainless steel armored cable.

Q9: Can it withstand high humidity?

A9: Yes, it is tested for ≤3% change in scale factor under 93% RH.

Q10: What certifications does it carry?

A10: It is certified for use in hazardous areas, meeting ATEX, IECEx, and CSA standards.

Related Models

| Model Number | Description | Length | Weight |

|---|---|---|---|

| 330101-00-20-10-02-05 | 3300 XL 8 mm Probe, unarmored | 1.0 m | 0.250 kg |

| 330103-00-20-10-02-05 | 3300 XL 8 mm Metric Probe, unarmored | 1.0 m | 0.250 kg |

| 330104-00-20-10-02-05 | 3300 XL 8 mm Metric Probe, armored | 1.0 m | 0.323 kg |

| 330105-02-12-10-02-05 | 3300 XL 8 mm Reverse Mount Probe | 1.0 m | 0.320 kg |

| 330191-00-20-10-02-05 | 3300 XL 8 mm Extended Temp Probe | 1.0 m | 0.300 kg |

| 330192-00-20-10-02-05 | 3300 XL 8 mm Extended Temp Probe, armored | 1.0 m | 0.340 kg |

Popular Bently Nevada Models

| Model Number | Description | Length | Weight |

|---|---|---|---|

| 330180-50-00 | 3300 XL Proximitor Sensor, Panel Mount | 5.0 m | 0.700 kg |

| 330130-060-00 | 3300 XL Extension Cable | 6.0 m | 0.240 kg |

| 3500/42M-01-00 | 3500/42M Proximitor Seismic Monitor | – | 1.2 kg |

| 3500/22M-01-01 | 3500/22M Transient Data Interface | – | 1.5 kg |

| 3500/25-01-01-00 | 3500/25 Keyphasor Module | – | 1.3 kg |

| 3500/15-05-01-00 | 3500/15 Power Supply Module | – | 1.8 kg |

Excellent PLC

Excellent PLC