| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

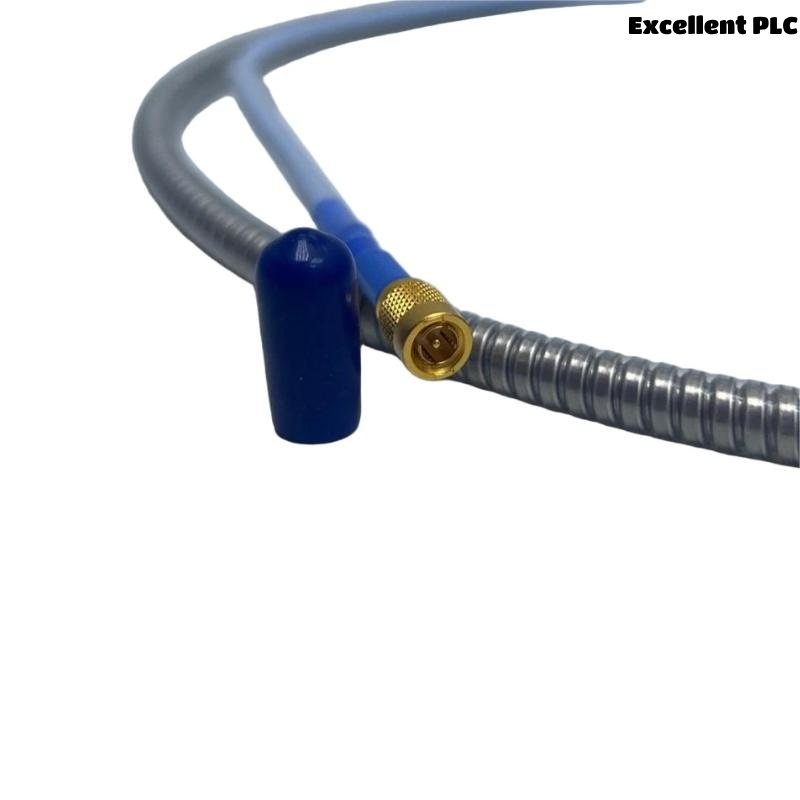

The Bently Nevada 330102-00-25-10-02-05 3300 XL 8 mm Proximity Probe is a high-precision sensor designed for continuous measurement of machine shaft vibrations and axial displacement. This probe is part of the 3300 XL series, a comprehensive line of proximity sensors used for critical machinery protection and condition monitoring.

Designed for use in high-performance applications across industries such as power generation, oil & gas, petrochemical, and manufacturing, the 3300 XL Proximity Probe provides accurate, real-time data on machine conditions. The probe’s non-contact eddy-current technology offers reliable performance in the harshest environments, with minimal wear and no physical contact with rotating machinery, ensuring long-term operational stability and safety.

Key Features

-

Precision Vibration and Position Measurement: The 3300 XL probe offers accurate shaft vibration and displacement monitoring for critical machinery.

-

Non-Contact Eddy Current Sensing: Reliable, wear-free measurement that avoids physical contact with the machinery, preventing wear and tear.

-

8 mm Probe Tip Diameter: Provides excellent precision for machine monitoring, suitable for most industrial applications.

-

Rugged, Industrial-Grade Design: Built to withstand extreme conditions in terms of temperature, vibration, and contaminants.

-

High Sensitivity: Capable of detecting very small vibrations, making it ideal for sensitive equipment.

-

Compatibility with Bently Nevada Systems: Fully integrates with the 3300 XL system, enabling seamless integration with vibration monitoring and protection systems.

-

Wide Operating Range: Ensures reliable operation across a variety of machine types and conditions.

-

Long Operational Life: Designed for durability and longevity in continuous duty applications.

-

Industry Certifications: Complies with CE, ATEX, and other relevant safety and environmental standards for global deployment.

-

Easy Installation: The probe comes with a standard mounting arrangement, enabling simple and cost-effective installation.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330102-00-25-10-02-05 |

| Product Type | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm (0.315 inches) |

| Sensing Technology | Eddy-current, non-contact |

| Measurement Range | 0 to 2 mm (adjustable based on system configuration) |

| Operating Temperature Range | -40°C to +120°C (high-temperature options available) |

| Frequency Response | DC to 20 kHz |

| Mounting Type | Standard 3/8-24 UNF thread |

| Electrical Connection Type | M12 or similar threaded connection for cable integration |

| Extension Cable Compatibility | Compatible with Bently Nevada 3300 XL series cables |

| Protection Class | IP67 (dust-tight and waterproof) |

| Certifications | CE, ATEX, RoHS |

| Dimensions | Total Length : 1.0 meter |

| Weight | 0.323 kg |

Industry Applications

-

Power Generation: Shaft vibration monitoring in turbines, generators, and compressors.

-

Oil & Gas: Monitoring of pumps, compressors, and turbines in upstream and downstream operations.

-

Petrochemical: Protects critical processing equipment, ensuring safe and efficient operation.

-

Manufacturing: Vibration monitoring for motors, conveyors, and other production machinery.

-

Mining: Provides early warning of vibration issues in crushers, mills, and other heavy-duty equipment.

-

Water Treatment: Monitors pumps and turbines in water and wastewater facilities.

-

Aerospace & Marine: Protects sensitive equipment on aircraft and ships from excessive vibration damage.

Product Advantages

-

Non-Contact Measurement: No physical contact with rotating machinery ensures no wear or degradation of the probe over time.

-

High Precision: Ideal for applications requiring highly sensitive detection of small vibrations or axial displacements.

-

Robust Construction: Built for harsh industrial environments, ensuring long-term reliability and minimal maintenance.

-

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL vibration monitoring systems.

-

Wide Range of Applications: Suitable for a wide range of industrial applications, including turbines, pumps, compressors, and other rotating machinery.

-

Long Service Life: The durable design minimizes maintenance requirements and extends the lifespan of the equipment.

-

Easy to Install: Mounting and installation are straightforward, reducing setup time and cost.

-

Global Standards Compliance: CE, ATEX, and other certifications ensure the probe meets international standards for safety and performance.

-

Real-Time Data: Provides immediate, real-time vibration data, enabling faster response times and better decision-making in machine protection.

Frequently Asked Questions (FAQ)

-

What does the Bently Nevada 3300 XL 8 mm Proximity Probe measure?

It measures shaft vibration and axial displacement in rotating machinery to monitor equipment health. -

What is the key advantage of the non-contact sensing technology?

Non-contact sensing prevents wear on the probe, ensuring long-term reliability and minimal maintenance. -

What is the operating temperature range of the probe?

The operating temperature range is from -40°C to +120°C, with options available for higher temperatures. -

Can the probe be used with other Bently Nevada monitoring systems?

Yes, it is fully compatible with Bently Nevada 3300 XL systems and related components. -

How sensitive is the probe?

The 3300 XL Proximity Probe is highly sensitive, capable of detecting small vibrations and axial displacements in sensitive equipment. -

Is the probe suitable for use in hazardous environments?

Yes, the probe meets ATEX and other safety certifications for use in hazardous environments. -

How does the probe connect to the monitoring system?

The probe connects using a threaded electrical connection (M12 or similar), which integrates with Bently Nevada extension cables and monitoring systems. -

Can the probe be used in high-vibration environments?

Yes, the probe is designed for high-vibration industrial environments and can withstand harsh conditions. -

What industries can benefit from the 3300 XL Proximity Probe?

Industries such as power generation, oil & gas, petrochemical, manufacturing, mining, and water treatment can all benefit from using this probe. -

What is the weight of the 3300 XL Proximity Probe?

The probe weighs approximately 0.323 kg, making it easy to handle and install.

Related Models

| Model | Description |

|---|---|

| 330102-00-10-02-05 | 3300 XL 8 mm Proximity Probe with a shorter length for compact installations. |

| 330101-00-16-10-02-05 | 3300 XL 8 mm Proximity Probe with extended cable length for large installations. |

| 330104-00-09-10-02-00 | 3300 XL Reverse Mount Proximity Probe for tight-space installations. |

| 330104-00-16-10-02-05 | 3300 XL 8 mm Proximity Probe for precision vibration monitoring in turbines. |

| 330180-91-05 | Velomitor Piezoelectric Velocity Sensor for machinery diagnostics. |

| 330130-045-00-05 | 3300 XL Extension Cable for proximity probe systems. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500/15-05-05-00 | 3500 Series Power Supply for monitoring systems. |

| 3500/22M-01-01-00 | 3500 Transient Data Interface Module for system diagnostics. |

| 3500/30-02-00 | 3500 Control and Monitor Interface Module for alarming. |

| 3500/33-01-00 | 3500 Series 16-Channel Relay Module for system control. |

| 330101-00-14-10-02-05 | 3300 XL 8 mm Proximity Probe for general-purpose vibration monitoring. |

| 3500/40-02-00 | 3500 Digital Output Module for critical control applications. |

Excellent PLC

Excellent PLC