| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

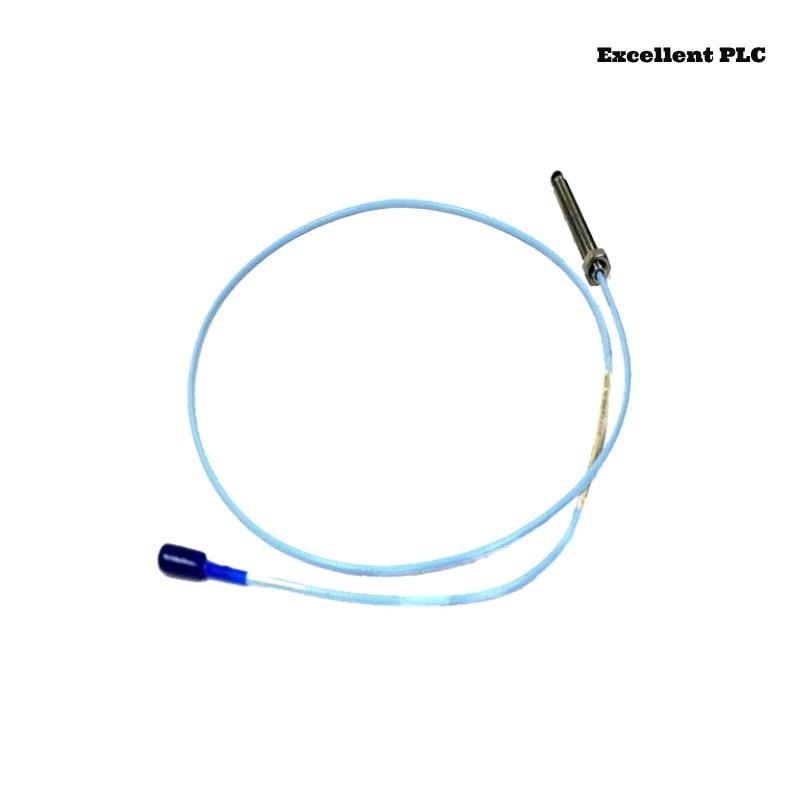

The Bently Nevada 330102-00-50-10-02-05 is a high-precision 8 mm proximity probe from the 3300 XL series, specifically designed for non-contact measurement of shaft displacement and vibration in critical rotating machinery. This probe is a vital component in predictive maintenance systems, ensuring machinery operates efficiently and safely.

With robust signal stability, high resistance to environmental factors, and excellent measurement accuracy, this probe is widely used in industries such as oil and gas, power generation, and manufacturing. It is engineered to work seamlessly with the 3300 XL Proximitor Sensor, forming a complete transducer system that delivers precise and reliable readings.

Product Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 3300 XL 8 mm Proximity Probe |

| Model Number | 330102-00-50-10-02-05 |

| Measurement Principle | Eddy Current |

| Shaft Measurement Range | 0 to 2.0 mm (80 mils) |

| Linear Range | 2.0 mm (80 mils) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Output Voltage | -2 VDC to -18 VDC |

| Power Supply | -24 VDC Nominal |

| Operating Temperature | -51°C to +177°C (-60°F to +350°F) |

| Environmental Protection | IP67 (Dust & Water Resistant) |

| Cable Length | 1.0 meters |

| Connector Type | ClickLoc™ Connector |

| Probe Tip Diameter | 8 mm |

| Thread Size | M10x1 |

| Probe Body Material | Stainless Steel |

| Weight | 0.323 kg |

| Certifications | ATEX, CSA, IECEx for Hazardous Locations |

Applications

The Bently Nevada 330102-00-50-10-02-05 proximity probe is used in various industrial applications where precise shaft vibration and displacement monitoring is required. Key applications include:

-

Gas & Steam Turbines – Helps detect early signs of misalignment or bearing wear.

-

Centrifugal & Reciprocating Compressors – Monitors rotor dynamics to prevent failures.

-

Pumps & Motors – Ensures proper alignment and detects early-stage damage.

-

Generators – Aids in the prevention of electrical and mechanical failures.

-

Gearboxes – Identifies abnormal wear and potential gear misalignment.

-

Fans & Blowers – Helps reduce downtime by detecting imbalances and vibrations.

Advantages of the 330102-00-50-10-02-05

-

High Measurement Accuracy – Ensures reliable and repeatable shaft displacement readings.

-

Robust Environmental Protection – IP67-rated for water and dust resistance.

-

Wide Operating Temperature Range – Designed for harsh industrial conditions (-51°C to +177°C).

-

Secure ClickLoc™ Connector – Vibration-resistant, ensuring stable data transmission.

-

Long Cable Length (5m) – Provides greater flexibility for installation in complex machinery.

-

Durable Stainless Steel Construction – Resists corrosion and harsh environments.

-

Seamless Integration – Fully compatible with 3300 XL Proximitor Sensors.

-

Certified for Hazardous Locations – Complies with ATEX, CSA, and IECEx standards.

Latest Industry News on 3300 XL Proximity Probes

-

Bently Nevada Unveils Next-Generation Condition Monitoring Solutions for Rotating Equipment

-

How 3300 XL Proximity Probes Improve Reliability in Power Generation

-

Oil & Gas Industry Adopts Bently Nevada Technology for Advanced Vibration Monitoring

-

Case Study: Increasing Equipment Uptime Using Non-Contact Proximity Probes

-

Bently Nevada Expands 3300 XL Series to Enhance Machinery Protection

Frequently Asked Questions (FAQ)

-

What is the main purpose of the Bently Nevada 330102-00-50-10-02-05 probe?

It is used for non-contact measurement of shaft vibration and displacement in rotating machinery. -

Is this probe compatible with older Bently Nevada monitoring systems?

Yes, it works with 3300 XL Proximitor Sensors and other legacy systems. -

Can this probe be used in hazardous environments?

Yes, it is ATEX, CSA, and IECEx certified for use in hazardous locations. -

What is the maximum operating temperature for this probe?

It can operate in -51°C to +177°C (-60°F to +350°F) conditions. -

How is this probe installed?

It is mounted using a threaded M10x1 fitting for secure and stable positioning. -

Does the probe require periodic calibration?

While factory-calibrated, it is recommended to verify calibration periodically for optimal performance. -

What materials are used in the probe construction?

The probe body is made of stainless steel for durability and corrosion resistance. -

Can I use a different cable length with this probe?

Yes, Bently Nevada offers different cable lengths to suit installation needs. -

How does this probe compare to the 5 mm version?

The 8 mm version provides a larger linear measurement range than the 5 mm variant. -

What kind of maintenance does this probe require?

The probe requires minimal maintenance, but routine inspections ensure long-term reliability.

Related Models from the Same Series

| Model Number | Description |

|---|---|

| 330103-00-05-50-02-05 | 3300 XL 8 mm Proximity Probe with 0.5m cable |

| 330104-00-10-10-02-05 | 3300 XL 8 mm Reverse Mount Probe with 1.0m cable |

| 330130-045-00-05 | 3300 XL 8 mm Probe with 4.5m cable |

| 330180-50-00 | 3300 XL 8 mm High-Temperature Probe |

| 330101-00-50-10-02-05 | 3300 XL 8 mm Probe with 5.0m cable |

| 330105-02-12-10-02-00 | 3300 XL 8 mm Reverse Mount Probe with 1.2m cable |

| 330106-05-30-10-02-05 | 3300 XL 8 mm Probe with 3.0m cable |

| 330108-00-07-10-02-05 | 3300 XL 8 mm Probe with 0.7m cable |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/42M | Proximitor/Seismic Monitor Module |

| 3500/22M | Transient Data Interface Module |

| 3500/32M | Relay Module |

| 3500/50M | Tachometer Module |

| 3500/25 | Keyphasor Module |

| 3500/15 | Power Supply Module |

| 330500 | Velomitor Piezoelectric Velocity Sensor |

| 3701/40 | Machinery Condition Monitoring System |

Excellent PLC

Excellent PLC